MINERVA trailing suction hopper dredger (TSHD), built by Royal IHC for DEME, is the world’s first LNG-powered TSHD.

DEME placed an order with Royal IHC for two LNG-powered trailing suction hopper dredgers in April 2015. The shipbuilder and the owner were presented DPC Innovation Award for the new concept of the vessels, in November 2016.

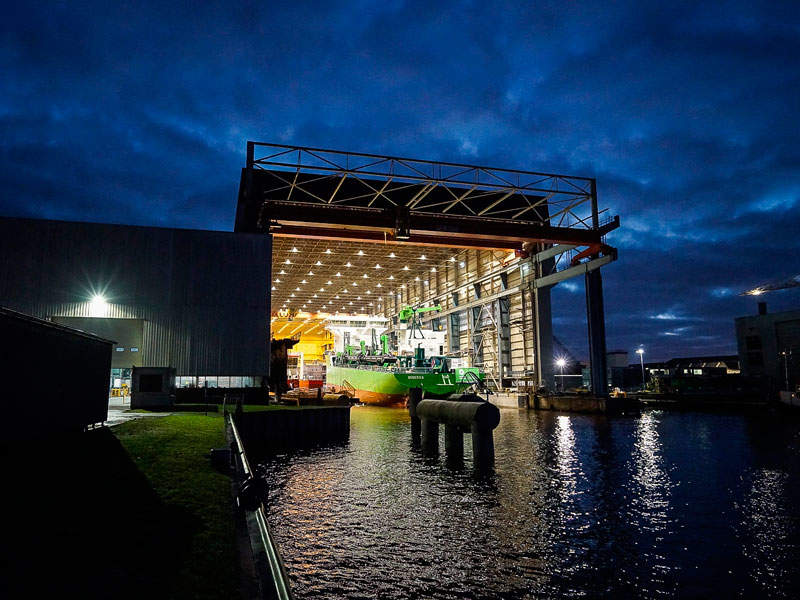

The MINERVA TSHD was launched at Royal IHC’s shipyard in Kinderdijk, the Netherlands, in December 2016. The naming ceremony of the vessel was held in June 2017 in Zeebrugge, Belgium. The vessel replaces the Orwell-class TSHD.

MINERVA was used for dredging works on the access channel at Port of Dublin in September 2017 and

deployed for beach nourishment works in Nieuwpoort in October 2017. It was also used for dredging, trenching and backfilling works for the 309MW Rentel offshore wind farm, in the Belgian North Sea.

MINERVA TSHD design details

The MINERVA dredger incorporates a hydrodynamic hull design powered by dual-fuel propulsion system. The innovative design enables the vessel to conduct maintenance dredging missions in shallow waters for extended periods.

The new-generation trailing suction hopper dredger complies with the extended dry-docking system requirements, extending the maximum dry-dock interval from five to 7.5 years. Some of the dry-dockings are replaced with in-water surveys.

The vessel has received ‘Green Passport’ and ‘Clean Design’ notations and complies with the stringent international emission standards.

The TSHD has an overall length of 83.5m, breadth of 18m, depth of 6.8m and design draught of 5m. It has a hopper capacity of 3,500m³ and can perform dredging up to a maximum depth of 30m. It offers accommodation for 14 personnel.

Equipment and systems aboard the TSHD

The integrated dredging control system (DCS) aboard the vessel effectively monitors and controls the dredging equipment including suction pipes, gantries, swell compensators, overflow ducts, gate valves, dredge pumps and auxiliary equipment through manual or automated modes or using artificial intelligence. The IHC Digisys software platform allows the DCS to execute the missions.

An 80cm suction tube is fitted for dredging to a depth of 30m. The ship can be installed with additional equipment such as degassing installations, wear-resistant pipes, bottom doors, bow couplings, self-emptying systems, jet pumps, nozzles and piping, screening systems and floating pipelines.

MINERVA TSHD propulsion

The vessel is powered by a Wärtsilä 12V34DF and a 9L34DF engine. The nine-cylinder engine has a rated power of 4,500kW, while the 12-cylinder engine develops a maximum power output of 6,000kW.

The propulsion system integrates two Wärtsilä controllable pitch propellers and two transverse thrusters. LNG to run the engines is supplied by the LNGPac gas supply and storage system.

The dual fuel engines allow the vessel to operate on either conventional liquid marine fuels or LNG. The engines can rapidly switch between fuels without loss of power and speed, enabling the vessel to operate in accordance with the regulations in emission-controlled areas, while providing the users an option to select the fuel depending upon the cost and availability.

The engine operating in gas mode complies with IMO Tier III regulations, without the need for the installation of any secondary exhaust gas purification systems. The gas-powered engine reduces the SOx and CO₂ emissions and ensures smokeless operation.

The engine operating in liquid marine fuel oil mode complies with the IMO Tier II exhaust emissions regulations. It can operate on low-sulphur fuels, allowing for operations in emission-controlled areas. The power-plant provides the vessel with a maximum speed of 12k.