Prelude floating liquefied natural gas (FLNG) facility is developed by Shell for its Prelude and Concerto fields in the Browse Basin, offshore Western Australia. It is the first FLNG development in the world.

The FLNG complex enables placement of the liquefaction facilities directly on the offshore fields. It is based on Shell’s own technology.

Prelude’s front-end engineering and design (FEED) was undertaken by the Technip Samsung Consortium (TSC), a joint venture of Technip and Samsung Heavy Industries. The same consortium is also responsible for the construction of the facility. Inpex, Korea Gas and CPC also respectively hold 17.5%, 10% and 5% stakes in the project.

Prelude was constructed at Samsung’s shipyard in Geoje Island in South Korea and placed at 475km offshore of Broome. It will be moored at the location for 25 years, when it needs an overhaul.

Purpose of the world’s first FLNG development

The FLNG facility processes gas at the field itself. It can prove economical to the fields where reserves are low and development of separate processing facilities may not be profitable.

The facility provides development of various small and remote offshore fields, which have not been tapped so far for their uneconomical propositions. Australia has 140tcf (trillion cubic feet) of stranded gas.

Shell initially utilises the facility to process gas extracted from the Prelude and Concerto fields, which have gas reserves of 3tcf. The fields are small and remote, thus making them suitable for the use of FLNG.

Design of the floating liquefied natural gas facility

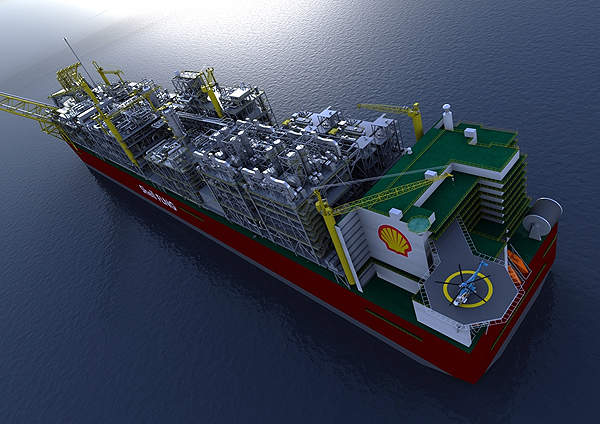

Prelude is 488m-long, 74m-wide and the topsides weigh more than 50,000t each. A fully loaded FLNG weighs 600,000t, six times more than an aircraft carrier.

The constructed facility is towed to the site and moored at a water depth of 250m, by four groups of mooring chains. The mooring chains are held by suction piles in the seabed.

The FLNG has been designed to overcome category five cyclones and is suitable to be used under severe metocean conditions in distant offshore fields.

The hull of the FLNG has tanks to store gas. More than 260,000t of steel was used in the construction of the facility.

Seven boiler units are installed on the topside for power generation and the LNG production processes. The facility comprises approximately 3,000km of electrical and instrumentation cables.

Development of Prelude, the largest floating facility in the world

Shell awarded the FEED contract to TSC in July 2009. It has simultaneously signed another contract with the consortium to design, construct and install multiple FLNG facilities over a 15-year period.

The decision to develop Prelude and Concerto fields using the FLNG technology was announced in October 2009.

The board of Royal Dutch Shell took the final investment decision on the project in May 2011 and TSC was asked, in the same month, to proceed with the construction. The first steel for the facility was cut in October 2012 and the keel was laid in May 2013.

Prelude was placed in its position in December 2017 and gas was later introduced for the first time onboard in June 2018.

Processes and economic benefits of Shell’s FLNG facility

The facility freezes the produced natural gas to -162°C and reduces the volume of the produce by 600 times. The gas is stored in tanks. The frozen gas is loaded to ocean-going carriers. The carriers also carry the by-products, such as condensate and LPG.

Prelude is estimated to produce 3.6Mtpa of LNG, 1.3Mtpa of condensate (equivalent to 35,000bbl/d) and 0.4Mtpa of LPG, totalling 5.3Mtpa of liquids.

The FLNG enables liquefaction of gas at the field itself, avoiding the need for land-based infrastructure such as pipelines, compression platforms, jetties and processing plants. This is economical while producing stranded offshore fields.

The facility requires less material, land and seabed areas than conventional onshore facilities.

The project created 350 direct jobs in Australia and also bring in tax revenues to the government. It also benefits the local businesses as Shell plans to make significant capital and operational investments in the facility. Construction of the facility employed approximately 5,000 people while an additional 1,000 people involved in the construction of the various equipment worldwide.

Contractors involved

GE Oil & Gas supplied two steam turbine-driven compressor trains, which are used to cool the natural gas.

Kawasaki Heavy Industries (KHI) provided seven boiler units, which produce 220t of high-temperature and high-pressure steam per hour.

Norsafe delivered free fall lifeboats, which have a capacity of 70 people and are certified for a drop height of 40m. SBM Offshore supplied the mooring systems.