XBEE Enzyme Fuel Technology is designed to clean up vessel fuel systems, dispersing all kind of organic contaminants, as well as water, and sludge.

Our natural fuel treatment reduces toxic gas emissions, fuel consumption, and maintenance costs. Enzymes can purify all marine systems, such as fuel tanks, filtering equipment, and engines.

Organic vessel fuel additive using biodegradable enzymes

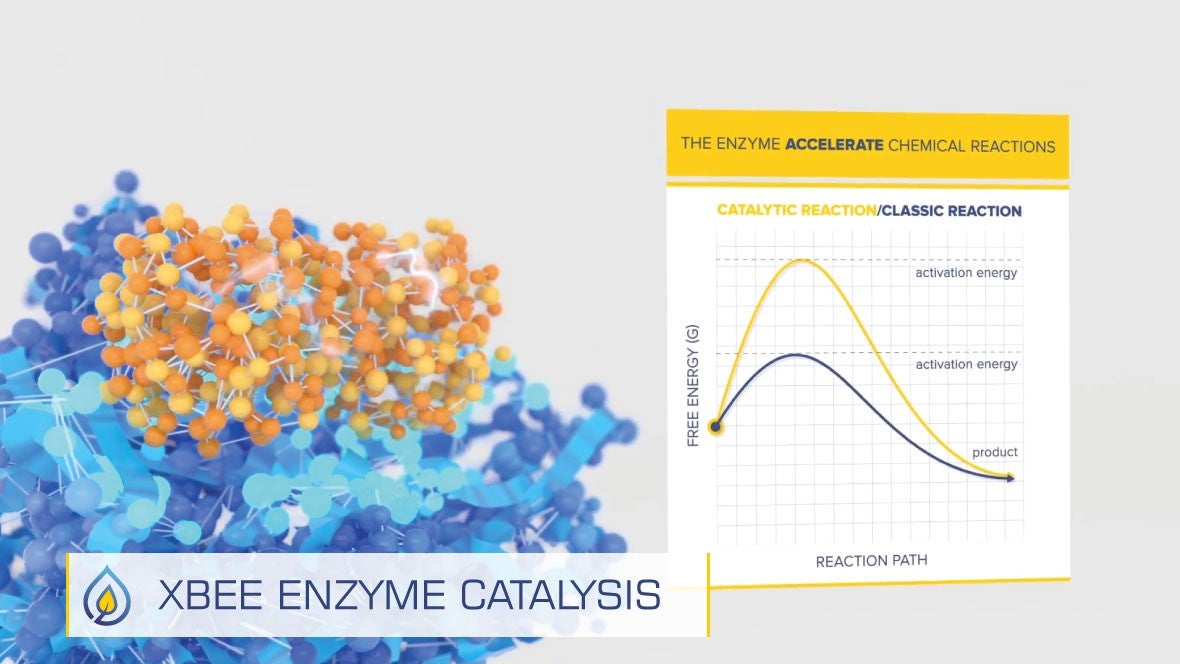

The organic composition of XBEE ensures it complies with all international fuel standards for gasoil, MDO, and heavy fuel oils. XBEE enzymes improve the molecular structure hydrocarbon molecules in fuel and increase the efficiency of the combustion process to prevent residue and carbon particles from being formed.

Enzymes are powerful dispersants and surfactants that take away the contaminant’s ability to stick to fuel tank walls.

Fuel additive to remove organic fuel-derived contaminants

XBEE removes natural contaminants found in fuel, helping to clean tanks and filters. It also minimises the workload for separators.

It is added during bunkering to ensure the optimal volume of the fuel technology is well dispersed throughout the fuel. XBEE is recommended for diesel, biodiesel and HVO, heavy fuel oils, and mazout.

Organic cleaning agent for ship engines

XBEE is a non-chemical agent that is compatible with all fuels and ship engines. The cleaning agent removes all contaminants from fuel, in addition to carbon deposits or soot in various parts of the engine.

The filtered fuel and elimination of contaminants naturally clean all engine components, such as pipes, valves, pistons, filters, and injectors.

Reducing fuel consumption and operating costs

XBEE restores the initial fuel consumption rate of engines through the removal of contaminants and other deposits in pipes and tanks. It also helps in preventing damage and wear to pumps and injectors.

Purified fuels burn faster and more efficiently in vessel engines, providing more power and reducing consumption.

Laboratories have measured specific fuel consumption reduction of -6.5% in diesel engines and -4,7% in HFO.

Environmentally friendly fuel additive for ships

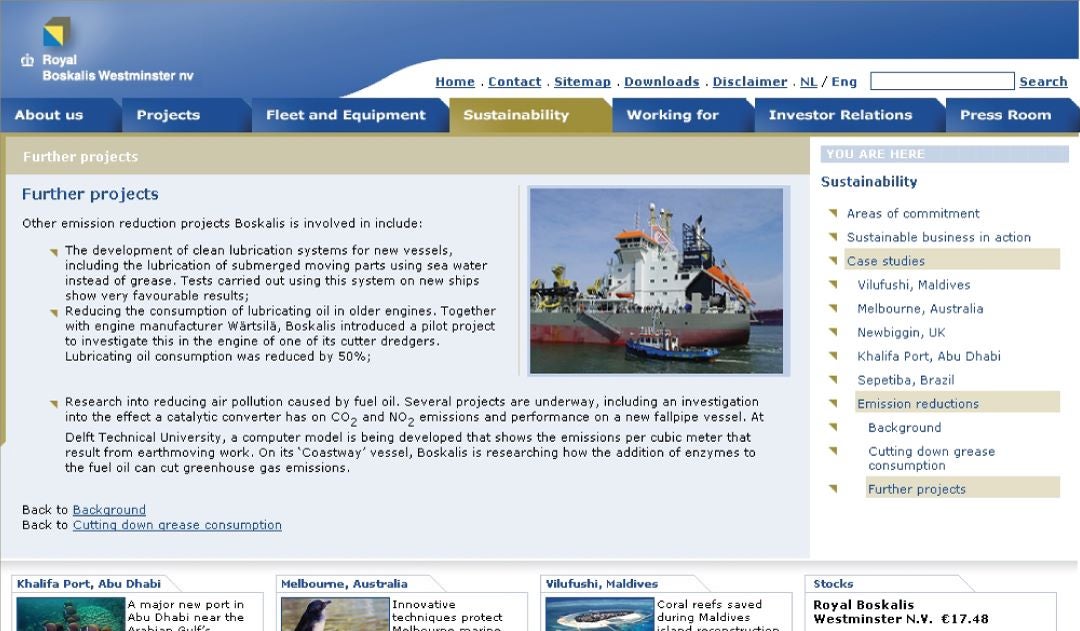

Vessels using XBEE can perform more efficiently, which means they will produce fewer greenhouse gas emissions, including carbon dioxide, nitrogen oxide, and other particles.

Said improvements have been repeatedly measured by laboratories, such as Bureau Veritas, Dekra, Eurofins, and SGS. All gas emissions, such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulates, are significantly reduced thanks to the action of the enzymes in the fuel.

About XBEE Enzyme Fuel Technology

Det Norske Veritas (DNV) has carried out analysis that shows XBEE is safe for maritime vessel engines and their components. Major original equipment manufacturers (OEMs) recognise or recommend the use of XBEE in their engines.

Fuels that have been treated with our technology comply with all standards, including EN590 for diesel and gas oil, and ISO 8217 for DMA and heavy fuel oil 180 and 380.