The Iran Delvar was built at the Dalian New Shipbuilding Heavy Industries yard in China for the National Iranian Tanker Company. This was the first Chinese yard to build such Very Large Crude Carriers (VLCC). The contract formed the first part of an order for five 300,000dwt tankers. These tankers have been designed to operate worldwide by filling the requirements of all the major oil companies.

The Iran Delvar has an overall length of 333.5m and the length between perpendiculars is 320m. It has a breadth of 58m and a depth of 31m. Its design draft is 21m and its scantling draft is 22.2m. The vessel is manufactured as a complete double skin double bottom unit with a bulbous bow and transom stern with an open water frame. It has two longitudinal bulkheads in the cargo area. The cargo tanks and engine room of the vessel are protected by ballast tanks. The Iran Delvar has a gross tonnage of 160,576t and a net tonnage of 98,368t.

ENGINES

The tanker has a freshwater generator consisting of two sets of Alpha Laval water generating units with a capacity of 45t/day. The VLCC is powered by a seven-cylinder Sulzer 7RTA84T-B low-speed marine diesel engine with an output 27,160kW at 74rpm. This is linked to three sets of heavy fuel oil Wartsila 9L20C units with an output of 1,490kW at 900rpm. There is also a 1,765kVA alternator for Gulf weather conditions as well as an emergency generator with an output of 399kW at 1,800rpm.

The ship has an auxiliary boiler system consisting of two sets of MHI vertical oil-fired units with a saturated steam capacity of 55t/h at 20kg/cm. There is also an Aalborg vertical water tube type exhaust gas boiler.

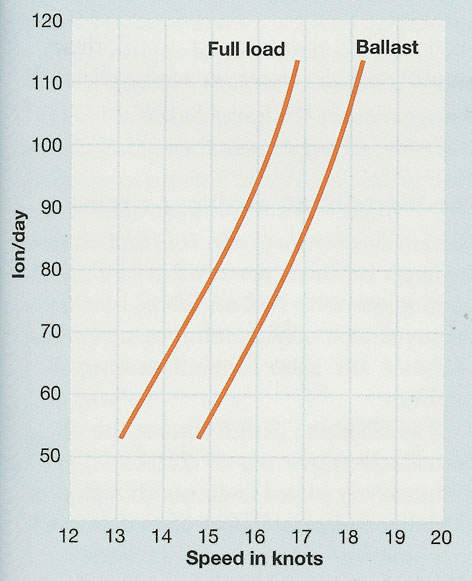

The engine is linked to a single screw four-bladed fixed pitch keyless LIPS propeller with a diameter of 10m. This gives the vessel service speed of 16 knots with 15% sea margin. Oil consumption is recorded at 97t/day in calmer conditions. Steering is carried out using a semi balanced rudder.

COMMUNICATIONS AND CONTROLS

The vessel has a Satcom B and C system as well as in Inmarsat mini M satellite terminal. It also has an integrated bridge system with two X-band and one S-band radar units as well as a planning station with chart digitiser and chart pilot. In addition, there is a stress monitoring system for the hull that lies adjacent to the ship’s loading computer. This gives the navigator details of the vessel and its measured and calculated stress condition at the same time.

There is also a track pilot and bridge monitoring system as well as an automatic identification system, voyage data recorder, engine control, echo sounder, Doppler speed log and independent gyro compasses. Vessel information is communicated via a fibre-optic based local area network (LAN) system consisting of two backup servers running Amosconnect software. Information is distributed to the wheelhouse, control room and cargo control room.

The Captain’s room contains a 21in monitor that shows X-band radar and ECDIS pictures. It displays information such as vessel performance traffic targets, speed course heading and position.

The Iran Delvar is classified by DNV under the notation +1A1 Tanker oil ESP SPM EO W1-OC LCS(SID) VCS2 HMON-1 NATICUS COAT-2 COMF-V(1) Clean.