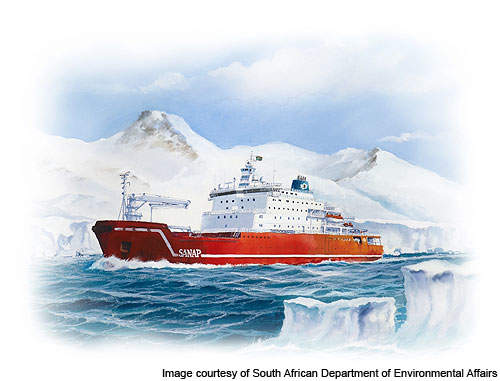

The South African Department of Environmental Affairs (DEAT) and STX Finland signed a contract worth €116m in November 2009, for the construction of the Polar Supply and Research Vessel. The contract is one of the biggest single civil trade pacts to date between South Africa and the Finish industry.

The vessel was being built to replace the DEAT’s existing polar supply and research ship SA Agulhas. Commissioned in 1978, SA Agulhas is operated and maintained by Smit Amandla Marine. It has taken at least one Antarctic replenishment voyage each summer.

The new vessel was named SA Agulhas II in July 2011. She was delivered in April 2012 after completion of sea trials in March.

SA Agulhas II was built by STX Finland’s shipyard in Rauma. She is operated and maintained by Smit Amandla Marine.

Design and construction

SA Agulhas II has been designed as a multi-purpose vessel, capable of serving as an icebreaker, research vessel, expedition vessel, supply vessel and cruise ship. The 134m-long ship is capable of accommodating 100 researchers / passengers and 45 crew members.

Construction of the vessel was launched in September 2010 and required nearly 600 person-years of employment.

In January 2010, STX contracted Ruukki for the delivery of 6,000t of shipbuilding plates for the vessel.

Raytheon Anschutz will supplied an integrated bridge system (IBS) for the vessel by the end of 2011.

Vessel accommodation and facilities

SA Agulhas II is classified as a cruise ship as it is furnished with some of the basic facilities such as accommodation, a library, a gym and a small sick bay that are available on a passenger ship.

The vessel features cabins, a day room for five officers and two passengers; single berth cabins for nine officers, eight passengers and 28 crew members; double berth cabins that can accommodate 40 passengers, four cadets and four crew; and four berth cabins accommodating 13 passengers.

Dining saloon, lounges, mess rooms, smoking rooms, pantries, conference/lecture room/cinema, a business centre with ten computer terminals, a baggage room and laundries with drying rooms also form part of the vessel.

Vessel features

SA Agulhas II was built primarily to carry out research operations and expeditions. It will be used to carry scientists and equipment for the South African National Antarctic Programme.

The vessel can be stationed for several months in the sea. Scientists can continue their marine research onboard as the vessel will operate as a mobile laboratory.

The vessel collects and transmits weather data for use by meteorological institutes around the world. It is also equipped with a helicopter deck, capable of accommodating two Puma class helicopters.

Navigation and communications

The vessel is equipped with a fully integrated navigation system in compliance with DNV’s NAUT-AW classification. It has six widescreen workstations for navigation.

She is capable of performing all the nautical functions of radar, chart radar, ECDIS (electronic chart display and information system) and conning.

The dynamic positioning system (DPS) allows the vessel to carry out most accurate operations within the ice fields.

The ice radar, with its ice imaging capabilities, helps the vessel to find out the best available route through icy waters. This way, the ship’s fuel consumption and the risk of hull damage is reduced.

The vessel has a dedicated communications system, allowing efficient transmission of observational data into a global telecommunications system (GTS). The ship also features an INMARSAT C or Iridium type communications system.

Propulsion

The vessel is powered by four six-cylinder in-line Wartsila 32 engines, enabling it to cruise at a maximum speed of 16kt and a service speed of 14kt. The engines help in mitigating fuel consumption and marine emissions.

Wartsila Corporation delivered four Wartsila 32 engines for the vessel.