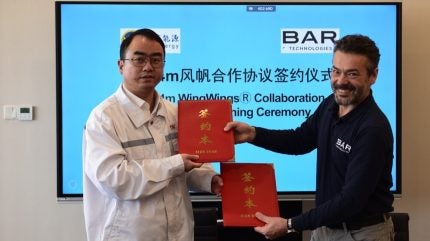

Shipping technology developer Bar Technologies has signed a collaboration agreement with CM Energy Tech (CMET) to commence production of the newly launched 20m and 24m WindWings models.

This partnership aims to meet the increasing market demand for wind-assisted propulsion systems from shipowners and operators of Handymax bulkers, chemical tankers, and general cargo vessels.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The new WindWings models build on the strong uptake of Bar Technologies’ existing 37.5m WindWings.

The models broaden the availability of wind-assisted propulsion technology across a wider range of vessels and are expected to contribute to fuel efficiency and emissions reduction efforts in the maritime industry.

The latest models align with industry-wide decarbonisation targets and have the potential to deliver up to 0.7 tonnes of fuel savings per WindWing per day on global routes, Bar Technologies said.

Bar Technologies CEO John Cooper said: “Bar Technologies’ innovative technology, combined with CMET’s advanced manufacturing expertise, allows us to efficiently scale production and deliver this pioneering solution to a wider market.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData“This partnership is built on a shared vision: accelerating maritime decarbonisation and providing shipowners with practical, future-ready solutions as they navigate evolving regulatory landscapes.”

The agreement comes at a time when shipowners seek cost-effective solutions to meet tightening regulations under FuelEU Maritime and the International Maritime Organization’s (IMO) 2030 emissions targets.

The WindWings models are designed for mid-sized vessels, offering a viable retrofit option without the need for major fleet modifications or investment in alternative fuels.

The models incorporate a fail-safe self-feathering mechanism that enables them to withstand extreme wind conditions of up to 100kt.

The patented three-element wing design generates 2.5 times the lift of conventional single-element wings, offering “enhanced” thrust and fuel efficiency.

Furthermore, WindWings do not require continuous power for suction fans or spinning mechanisms, ensuring minimal energy consumption.

Its fully adjustable camber and angle of attack allow for automatic optimisation based on wind conditions, improving operational performance.

The models are available in both foldable and non-foldable variants, providing flexibility for navigation during port operations and pilotage.

With a lightweight design of under 30 tonnes, the models require minimal deck reinforcement, making them suitable for both newbuilds and retrofits.

Operating entirely on electric power, WindWings are designed to integrate seamlessly into existing vessel infrastructure.

In November 2024, Bar Technologies signed a memorandum of understanding with Mitsubishi and Nihon Shipyard to promote wind propulsion in Japanese shipbuilding.