Hyundai Mipo Dockyard (HMD) is set to deliver a new 7,600m³, ballast-free liquefied natural gas (LNG) bunkering vessel to its owner, Bernhard Schulte Ship, in Germany later this year.

The vessel is currently under construction at HMD’s shipyard in Ulsan, South Korea.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

It will be classed by Lloyd’s Register (LR) and is designed to help Bernhard comply with the International Maritime Organisation’s (IMO) new Ballast Water Management Convention, which came into force in September last year and requires all new ships to feature a ballast water treatment system.

However, the new vessel’s ballast-free design is anticipated to eliminate for an onboard ballast water treatment system.

In addition, the concept removes the need for the ship to comply with the Performance Standard for Protective Coatings for ballast tanks, as well as other related regulations.

It is also expected to offer maintenance costs savings.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataHMD Initial Planning Division senior vice-president Seung-Ho Jeon said: “The ballast-free concept will be made a reality by the technology expertise of HMD.

“We aim to stand out in the field of eco-friendly business practice.”

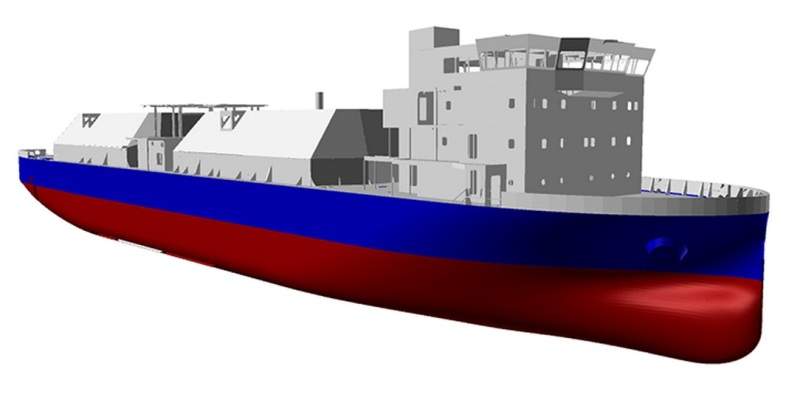

HMD developed a special hull form in order to integrate the ballast-free concept into the vessel design, which features deadrise, a forward ‘engine room and deckhouse’ and a twin propulsion system equipped with azimuth thrusters.

The inclusion of these solutions is set to help the vessel retain its damage stability and allow it to easily control the trim and heel without ballasting.

The smaller diameter of the vessel’s propellers will also allow it to achieve full immersion in all operational conditions.

LNG will be stored on-board the ship in two separate IMO type-C tanks, which will maintain a minimum temperature of -165°C and maximum vapour pressure of 3.75 bar(g).

The fuel is expected to be transferred to LNG-powered vessels at a rate of roughly 1,250m³/hour via cryogenic flexible hoses without ballasting and / or de-ballasting operations.