The Dragon-class liquid gas transport vessels are a series of eight, identical multi-gas carriers ordered by Danish ship operator Evergas. The vessels are among the world’s biggest ethane carriers.

Evergas has signed contracts with Sinopacific Offshore & Engineering (SOE) for the design and construction of a series of 27,500m³ multi-gas carriers in April 2013.

In January 2013, Evergas signed 15-year charter agreements with INEOS for transporting ethane to Europe from the Mariner East project in the US, beginning in 2015. Under the agreements, Evergas provides and operates customised vessels to transport ethane supplies to INEOS’s facilities. The contract was expanded to six vessels in May 2014.

The Triple-E class container ships are to be built by South Korea’s Daewoo Shipbuilding & Marine Engineering (DSME).

INEOS signed an agreement with Evergas in November 2014 for the extension of the new-build vessels from six to eight units. The fleet of eight vessels will transport shale gas from the US to INEOS’s petrochemical complexes in Grangemouth, Scotland, and Rafnes, Norway.

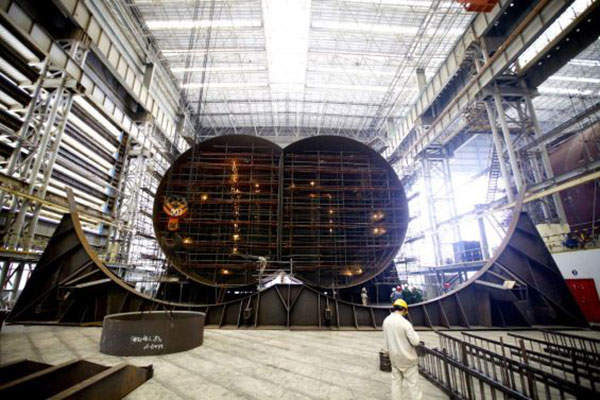

Dragon-class construction

The Dragon-class vessels are being constructed jointly by SOE and Sinopacific Shipbuilding Group (SSG).

SSG is responsible for the construction of the hull, while tanks and cargo system are designed and fabricated by SOE. The vessels are being delivered from SOE’s Qidong construction base.

Wärtsilä was awarded a contract to supply integrated solutions for the vessels in April 2013.In association with Wärtsilä and Wärtsilä Oil & Gas Systems, SOE completes the installation of the dual-fuel power-plant, LNG fuel system, and gas plant system on the liquid gas carriers.

The first vessel was floated out of the No.3 quay of Sinopacific’s Dayang shipyard in April 2015. It was delivered to Evergas in May 2015. Construction of second and third vessels was completed in 2015.

Deliveries of third, fourth and fifth vessels were concluded in October 2015, January 2016 and December 2016, respectively.

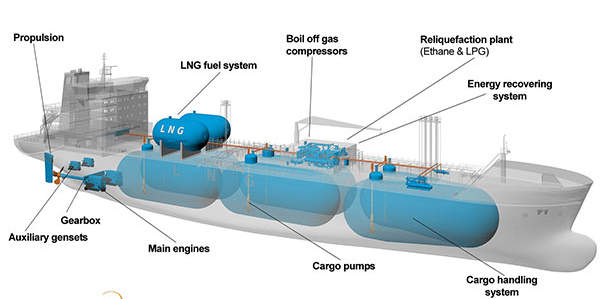

Design and features of Dragon-class multi-gas carriers

The vessels incorporate an entirely new design, which was developed in-house by SOE in concert with Evergas. The modern design includes a range of innovative features such as the optimised ECO hull form and the LNG dual-fuel propulsion.

The advanced capabilities of the Dragon-class will improve efficiency, while reducing emissions. The ballast water treatment system will further safeguard the marine environment. The vessels carry EP-class notation and green passport, comply with the energy-efficiency design index (EEDI) regulations, as well as NOx and SOx Tier III standards.

Each Dragon-class vessel has a length of 180m, a width of 26.6m and a draft of approximately 9m.

Dragon-class storage and cargo handling

The Dragon-class vessels are equipped with autonomous C type bi-lobe tanks, which store 27,500m³ of gases, such as liquefied natural gas (LNG), ethane, liquefied ethylene gas (LEG), and liquid petroleum gas (LPG).

The multi-gas carriers are also installed with boil-off gas compressors, cargo pumps and an energy recovery system. The Wärtsilä comprehensive cargo handling package aboard the vessel includes the deck tank, cargo handling equipment and systems, as well as a purpose-built re-liquefaction plant for LPG and ethane.

Propulsion of the liquid gas transport vessels

The power-plant integrates two Wärtsilä 6L50DF dual-fuel engines, and Wärtsilä propulsion equipment, including the gearbox, two Wärtsilä 6L20DF ancillary generators and a Wärtsilä LNG fuel system. Each engine develops a power output of 5,850kW.

The Wärtsilä Energopac rudder fitted to the vessel lowers resistance and increases propulsive energy by streamlining the water flow from the propeller. It also helps to improve efficiency and reduce fuel consumption.

The Wärtsilä propulsion offers operational flexibility as it allows for the usage of other conventional fuels in addition to LNG.