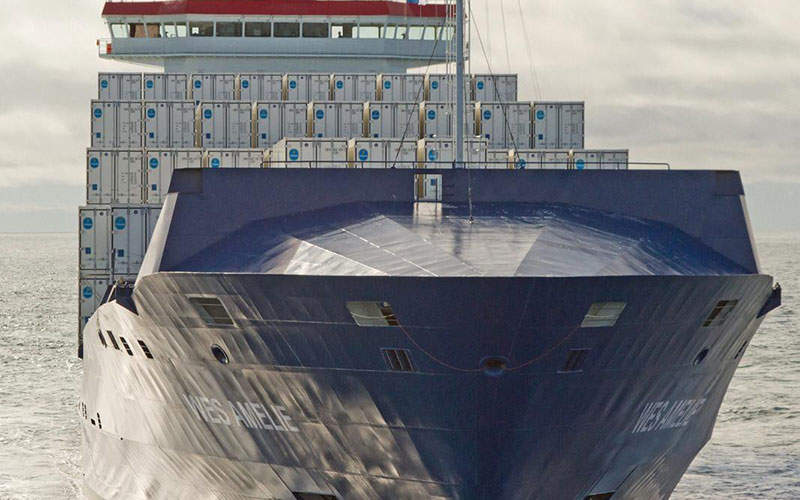

German shipping company Wessels Reederei contracted MAN Diesel & Turbo to retrofit Wes Amelie, a 1,000TEU feeder container ship, to enable dual-fuel operation in November 2015.

Wes Amelie is the ship first of its kind in the world to be transformed into a liquefied natural gas (LNG) powered vessel.

The LNG conversion is expected to ensure that the ship significantly reduces its sulphur oxide emissions by more than 99%, nitrogen oxide emissions by approximately 90% and carbon dioxide by up to 20%.

The Federal Ministry of Transport and Digital Infrastructure released a grant for the vessel’s retrofit in October 2015 through the Mobility and Fuel Strategy programme, which was launched to promote maritime use of LNG as an environment-friendly fuel.

MAN Diesel & Turbo performed the conversion at its German shipyard in the fourth quarter of 2016.

The completely converted LNG powered vessel was subsequently launched in August 2017 and the conversion project was formally concluded in September 2017.

The dual-fuel vessel meets the emission requirements set by the International Maritime Organisation (IMO).

It also achieved a significant reduction in particulate and CO2 emissions and will be compliant with future stringent tier III emissions set by the IMO.

Wes Amelie conversion project details

Wes Amelie is a modern feeder vessel operating in the North and Baltic Seas that was originally launched in 2011.

Significant efforts were made to achieve a noticeable multiplier effect through the selection of the vessel for conversion, which is intended to benefit follow-up refit projects.

Other factors considered during the selection process included the scalability of engineering services, development costs and costs of follow-up projects.

Wes Amelie has a toal of 23 sister ships, including 16 that are structurally identical, making it easy to execute follow-up projects after the first conversion.

The common conversion model also reduces various costs involved with consecutive conversions, preventing the need for further financial support.

Technical specifications of Wes Amelie container ship

The vessel was built according to a German-Dutch design and has an overall length of 151.72m and beam of 23.4m.

It has a deadweight of 13,200 metric tonnes (mt), a gross tonnage of 10,585mt and net tonnage of 4,958mt.

The vessel has a maximum service speed of 18.5k and an economical speed of 13k.

It can carry up to 1,036 TEUs, 403 45ft containers and 740 14t containers.

The ship has been classified by Bureau Veritas (BV) as BV + 1 HULL AND MACH INWATER SURVEY AUT – UMS ICE 1A CONTAINERSHIP (EQUAL FINISH-SWEDISH).

Wes Amelie LNG-fuelled propulsion

Wes Amelie was originally fitted with a MAN 8L48/60B main diesel engine with a continuous rating of 9,000kW at 500rpm, which was later replaced with a multi-fuel, four-stroke MAN 51/60DF engine.

Engineering manufacturer MAN Diesel & Turbo collaborated with gas specialist TGE Marine Engineering to assist in the engine conversion, which included the reconstruction of the main engine plant and installation of a new LNG tank.

Several components of the combustion chamber and associated systems were replaced, including the water cooling jacket, pistons, piston rings, injection components and cylinder head.

The cylinder bore was also increased from 48cm to 51cm and the pilot oil system for gas operation was completely reconstructed.

New valve cams and a turbocharger rotor assembly were added to allow for a change of ignition timing for the new engine.

The vessel’s engine sensors were also converted and new instruments were installed to optimise the performance of the new engine.

The entire conversion process required approximately 30t of material.

Key players involved

MAN Diesel & Turbo supplied the conversion components required for the conversion programme.

The necessary calculations and blueprints for the conversion and installation initiative were provided by engineering company SMB Naval Architects & Consultants.

TGE Marine Gas Engineering provided tank and LNG components for the project.

Increasing popularity of low-emission propulsion systems

The transition to low-emission propulsion systems is gaining importance in the shipping industry as a result of the 2015 Exhaust Emission Directive, which was released by the IMO for the Emission Controlled Areas (ECAs) of the North and Baltic Seas.

Wessels Reederei, along with its partners MAN Diesel & Turbo and TGE Marine Gas Engineering, have been working on a possible conversion of 1,000TEU container ships from heavy oil to low-emission LNG operation since 2013.

The company has also studied the installation of an emission control system (scrubber), which would allow the use of heavy fuel oil in ECA zones.

LNG operation is still preferred as an ideal solution, however, as scrubbers offer poor environmental performance compared to LNG propulsion.