Strainstall

Marine Safety Systems for On-Board, Onshore and Offshore Applications

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Marine safety systems work year after year in changeable and often hazardous environments. Reliability is essential, as vessels and equipment on the move around the world depend on the systems to ensure safe operation. Strainstall have experience in providing long-term solutions for the unpredictable and often severe challenges posed by marine operations.

Strainstall’s marine safety products include jetty management systems, vessel approach monitoring systems, mooring load monitoring systems and hull stress monitoring systems.

Our custom-designed integrated multi-sensor packages are supported by comprehensive installation and after-sales services.

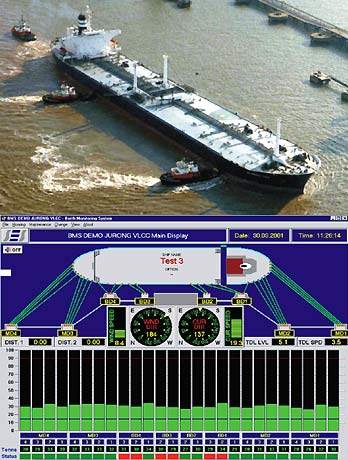

BERTH MANAGER – JETTY MANAGEMENT SYSTEM

Based on more than 40 years of experience in load and force measurement, Strainstall’s Berth Manager system is designed to assist the mooring master by providing comprehensive surveillance of mooring and vessel-related parameters during approach to the berth, and while moored.

Sensors monitor speed of approach, mooring loads, weather conditions, oceanographic parameters and detect any drift off. All of these values are processed and presented on a PC-based control room display system, which provides graphics and lists of all critical data, and which is available on screens in the harbour office and via fibre-optic link or radio to the ship.

The Berth Manager jetty management system integrates a number of sub-systems which are all available as standalone packages. These systems are:

- DockAlert vessel approach monitoring – provides speed, distance off and drift-off data

- MoorAlert mooring load monitoring – provides mooring set-up, mooring tension and alarm data

- Meteorological / oceanographic monitoring – provides weather and sea-state information for reference

DOCKALERT – VESSEL APPROACH MONITORING

The Strainstall DockAlert vessel approach system uses distance-measuring lasers on the mooring jetty to compute the speed of approach, angle of approach and distance off for a vessel being manoeuvred onto a dockside mooring.

The vessel approach parameters can be displayed in the harbour office and can also be made available to the ship’s master via a large digit display on the jetty which is visible from the ship, or via a data link. With the vessel moored alongside, DockAlert can provide information on drift-off and fender compression. External items can be supplied certified for hazardous areas to meet the requirements of oil and gas jetties.

MOORALERT – MOORING LOAD MONITORING

Strainstall’s MoorAlert mooring load monitoring system provides an accurate indication of mooring loads in multi-line mooring spreads. A vessel’s mooring lines are measured and monitored by strain-gauged load measuring pins, installed in the quick release mooring hooks. This enables each mooring line to be pre-tensioned according to each vessel’s individual mooring scheme. The load pins detect any deviation from these defined values and indicate any alarm conditions.

The instrumented hooks and electronics can be supplied in hazardous area certified form for use on oil and gas jetties, and have been supplied to many port and harbour installations worldwide.

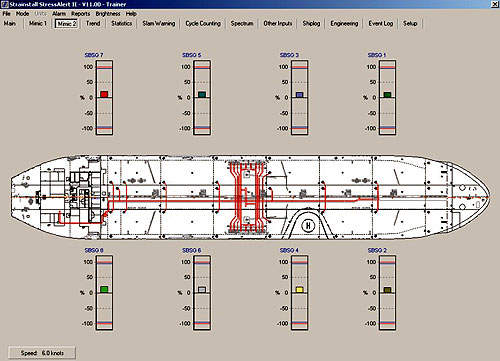

STRESSALERT – HULL STRESS MONITORING

StressAlert enhances vessel safety by maintaining a log of hull stresses throughout the life of a ship, and warning the master in real-time of any overstress or bow slamming. This is achieved by continuous measurement of the hull using deck-mounted long baseline strain gauges and a bow accelerometer to provide displays of bending moments, alarms when unsafe levels of stress are experienced, detection of bow slamming and long-term monitoring of fatigue.

Additional sensors (bow pressure, wave height, heave / pitch / roll) can be fitted to meet more advanced certification requirements.

StressAlert is in use with major ship operators around the world, and installations have been approved by the major certifying authorities, including DNV, LRS, ABS, BV, etc.

Contact Details

Website

Email Address

Address

Cowes,

Isle of Wight,

PO31 8PD,

Other,

United Kingdom