Burckhardt Compression provides compressor installations for applications within the shipping industry, including liquefied natural gas (LNG) fuelled merchant ships, floating storage and regasification units (FSRU) and LNG bunker vessels.

Solutions for compressing fuel gas on ships

For advanced fuel gas control, Burckhardt Compression offers a range of compressor solutions that can withstand dynamic suction or discharge pressure, as well as changes in mass flow, gas temperature and composition.

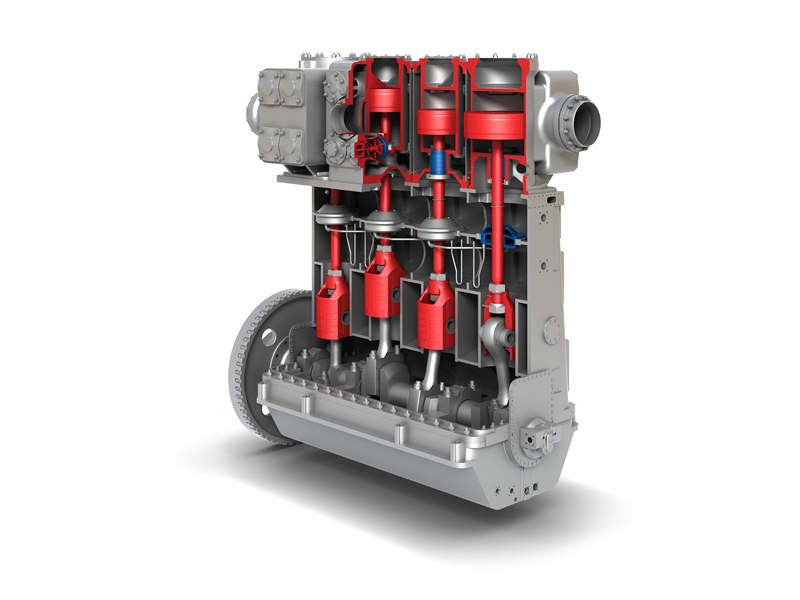

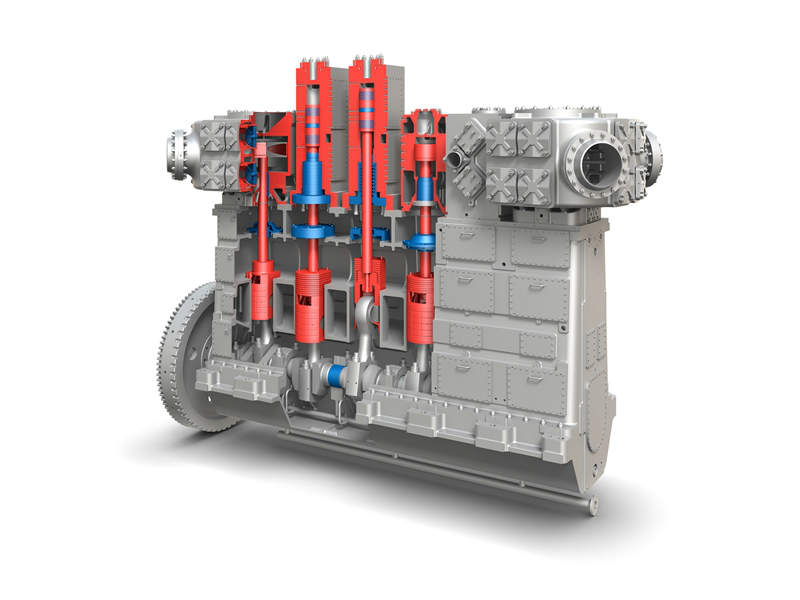

The Laby®-GI Compressor fuel gas solution offers the additional capacity of enhancing operations with its temperature-resistance that removes the need to preheat gas or pre-cool compressors. The system is contactless and oil-free, allowing operators to instantly power-up the compressor.

Integrated boil-off gas compressors for the marine industry

The solution allows boil-off gas (BOG) to be reused as fuel, or returned to tanks after being reliquefied. Fuel capacity can also be controlled from 0% to 100%, providing optimum natural gas regulation.

The Laby-GI can tolerate gas composition, as well as suction temperature and pressure, operating proficiently across a wide range of applications.

Operational efficiency is enhanced with the Laby-GI Compressor’s ring-sealed technology. Its integrated multi-purpose compression capabilities remove the need to use multiple pieces of equipment for different pressures.

Laby-GI is fully balanced and vibration-free, minimising damage to tank systems, and made with high-quality Swiss technology to deliver robust slow-speed compression.

Compression for LNG fuel tanks on merchant ships

An increase in the number of LNG powered merchant ships means that there is also a growing demand for compression tanks. Various sizes of LNG tanks are available to suit a range of functions, including different container systems for storing LNG fuel.

Tanks are fitted with an option to control pressure caused by gas constantly evaporating. As a cost-effective alternative to reliquefaction or flaring, BOG can be used in on-board main propulsion or auxiliary engines.

Vessels with dual-fuel engines can use Burckhardt Compression’s solutions in diesel cycles for injection pressure of up to 350bar.

Compressors are designed so that they can be easily serviced by crew on-board ships.

Enhanced capacity for ship fuel gas supply

Burckhardt Compression provides FSRUs as a cost-effective method of enhancing the capacity of an on-board gas supply.

The amount of BOG created each hour varies depending on multiple factors, including tank size and insulation, as well as its LNG capacity.

FSRUs allow BOG to be used in reliquefaction, or as a fuel supply for twin fuel engines or gas combustion units.

LNG refuelling bunker vessels

Burckhardt Compression’s LNG bunker vessels are used to refuel ships at sea. They are designed so tank pressure can be regulated to manage the continuously evaporating LNG.

The company’s marine compressors provide simple and efficient storage of BOG, even within restricted spaces.

Solutions are compatible with leading marine propulsion systems, including Wärtsilä XDF, Bergen / Rolls-Royce, MAN B&W ME-GI, and Caterpillar MaK.

About Burckhardt Compression

Burckhardt Compression is a recognised worldwide leader in compressor technology, having provided more than 2,000 installations since 1962. Proven design and operation are a testament to the company’s decades of providing compressing solutions to the offshore and shipping industries.