On April 1st 2010 maxit changed name to Weber. Weber is a wholly-owned subsidiary of the Saint-Gobain Weber, which is Europe’s leading manufacturer and supplier of materials and solutions to the building and marine industry. The Weber group is a part of the worldwide operating building materials group Saint-Gobain.

Fire-insulated ship floors

Weber supplies functional and durable floors specified for ships requiring fire insulating constructions with non-combustible materials, sound insulating constructions, primary deck coverings, and more. Floors for marine applications are subject to extreme stresses, such as knocks, vibrations and tremors, torsions and shrinkage where failure to adhere are common industry problems.

By installing a Weber Marine Floor you avoid these challenges. The decisive benefits of the Weber range of marine solutions are the efficient properties of the solutions – speed of application and access.

Pumpable ship floors

The Weber range of products are pumpable, reducing the time needed for screeding, thus ensuring installation of primary deck covering at 300m²/hr to 500m²/hr that is walkable after one to three hours. Floor covering can be laid after just one to three days.

Pumpable self-levelling ship floor screeds

The Weber Premix range leads the world in production of pumpable cementations self-levelling floor screeds.

Weber Marine Flooring systems are built layer by layer to provide the optimum solution for each individual client’s requirement. Pumpable self-levelling floor screeds allow you to achieve the flattest, smoothest and thinnest floors possible, performing to exact standards even in highly demanding environments. They are pre-mixed at the manufacturing plant, and boast the following benefits:

- Factory blending to ensure consistent quality

- Machine mixing, guaranteeing optimum consistency

- Choice of delivery in bags, bulk or pump trucks

- Pumpable form to minimise downtime and enhance ergonomics

- Rapid drying time, meaning floors are walkable after one to three hours

- High strength / low thickness mix to minimise loss of floor to ceiling height

- Self-compacting and self-levelling; ready to surface finish after one to three days

- Marine flooring systems only installed by accredited Weber contractors – Accredited Weber Marine Floor Contractors

Weber Waterproofing System

Weber waterproofing (previously Deitermann – a company in the maxit Group) has products and systems for various construction chemical application areas. These modern-construction chemical products and systems are flexible in use and therefore ideal for applicators, architects, contractors, planners and construction workers. This flexibility is ensured by the work carried out by highly qualified specialists in our research and development department.

For marine applications, Weber has developed a complete wet area system that is DNV approved.

Weber Marine Primary Deck Covering

Weber Marine Primary Deck Covering features flexible, durable pumped screed systems for steel decking with a low constructional height. The fresh surface can be smoothed gently with a toothed spatula to give a perfectly smooth surface.

Weber Marine A-60 Floor

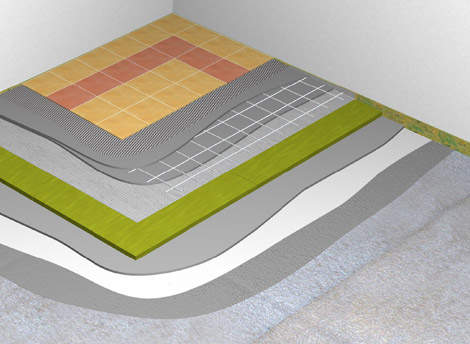

This system is DNV A-60 approved and recommended for ship installations requiring fire-insulating constructions where the material must be non-combustible according to IMO rules. It is composed of following layers:

- 50mm of insulation, approved type according to DNV certificate

- Steel reinforcement net of 5mm in diameter and a grid of 150mm x 150mm

- Interglas woven glass fabric with weight 100-3000g/m², or equivalent non-combustible product

- 25mm of Weber.floor 4665 Marine Fire

Weber Marine Light dB Floor

The Weber Marine Light dB Floor is a flexible, durable pumped screed system for steel decks, with low constructional height and structure borne sound insulation. It comprises a:

- 1,5mm Visco Elastic layer (ACM, DG U-1 or DG U-1 Green, from Swedac)

- 15mm Weber.floor 4660 Marine Elastic

Weber Marine dB Floor

The Weber Marine dB Floor is recommended for ships and offshore installations requiring sound-insulation, effective against airborne, impact and structure-borne sound. Composed of following layers:

- 1,5mm Visco Elastic layer (ACM, DG U-1 or DG U-1 Green, from Swedac)

- 15mm Weber.floor 4660 Marine Elastic

- 50mm of insulation, approved type according to DNV certificate

- 1,2 mm fibertextile GeoPro SI 401 from GeoTippTex with weight 135 g/m2, or equivalent

- Steel reinforcement net of 5mm in diameter and a grid of 150mm x 150mm

- 25mm Weber.floor 4665 Marine Fire

Weber Marine dB A-60 Floor

The Weber Marine dB A-60 Floor is recommended for ships and offshore installations requiring fire-insulated constructions and sound-insulation. System is composed of the following layers:

- 1,5mm Visco Elastic layer (ACM or DG U-1 Green, from Swedac)

- 15mm Weber.floor 4660 Marine Elastic

- 50mm of insulation, approved type according to DNV certificate

- Interglas woven glass fabric with weight 100-3000g/m2, or equivalent non-combustible product

- Steel reinforcement net of 5mm in diameter and a grid of 150mm x 150mm

- 25mm Weber.floor 4665 Marine Fire

Certification and approvals

The Weber range of marine products satisfies the requirements stipulated by the authorities and leading classification societies. All our marine self-levelling compounds and flooring systems are design approved by DNV. The manufacturing process is also registered in accordance with SS-EN ISO 14001:2004 and SS-EN ISO 9001:2000.