As many industries start to move away from relying on fossil fuels, offshore wind energy has become a promising alternative source of renewable energy. It also has the potential to contribute significantly to generating electricity on a global scale. The renewable wind energy industry has rapidly progressed over the last several years, which is due to the industry beginning to use technology that was previously developed and tested for the oil and gas industries. Using this technology means that developing and certifying new wind technology has become much quicker and easier, as the wind energy industry has been able to benefit from the experience gained in other sectors.

Anchors for offshore wind farms

Offshore floating wind farms face many challenges, including anchoring the structures in a way that is both secure and efficient. Traditional designs use suction anchors as the main anchoring solution for offshore floating structures across the world. The large suction anchors are beneficial during storms and bad weather conditions, but they are expensive to install and require the use of large crane vessels.

At Deep Sea Anchors, general manager Dr. Jon Tore Lieng created the perfect solution to this issue with the development of the Deep Penetrating Anchor (DPA) concept. The DPA design features a dart-shaped body, with a rounded front tip and pronounced fins. This ellipsoid shape is a cross between a cone and a sphere. DPA-style anchors are also cheap to manufacture due to their simple design. Approximately 65% of the main anchor body is composed of high grade steel and the remaining mass is made from inexpensive ballast material, which helps to significantly lower costs. This is important for floating wind farms as it helps developers to reduce costs across the entire project.

So far, over 2000 similar style anchors have been used for anchoring offshore floating structures in deep waters offshore Brazil. These have all been very successful, thus demonstrating the viability of gravity installed anchors.

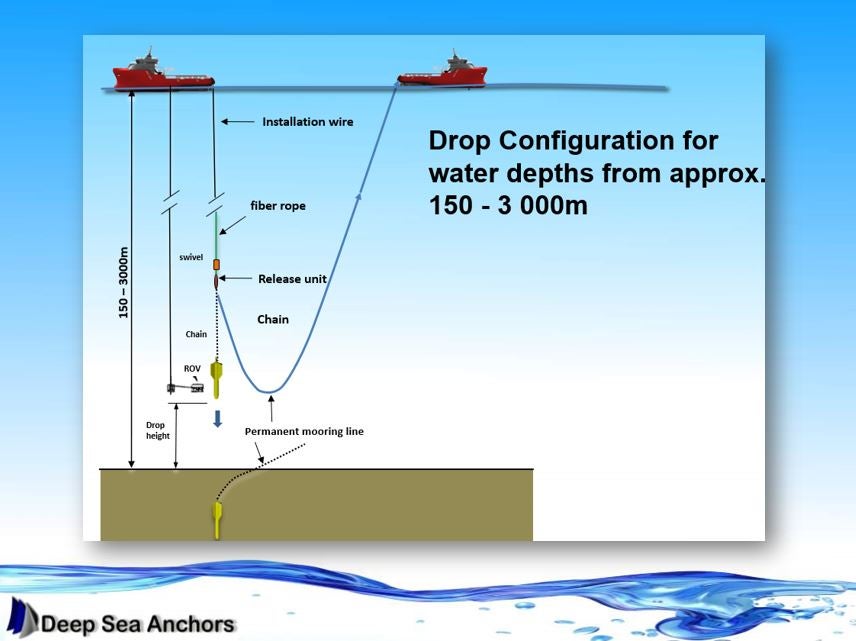

DPA deep water installation

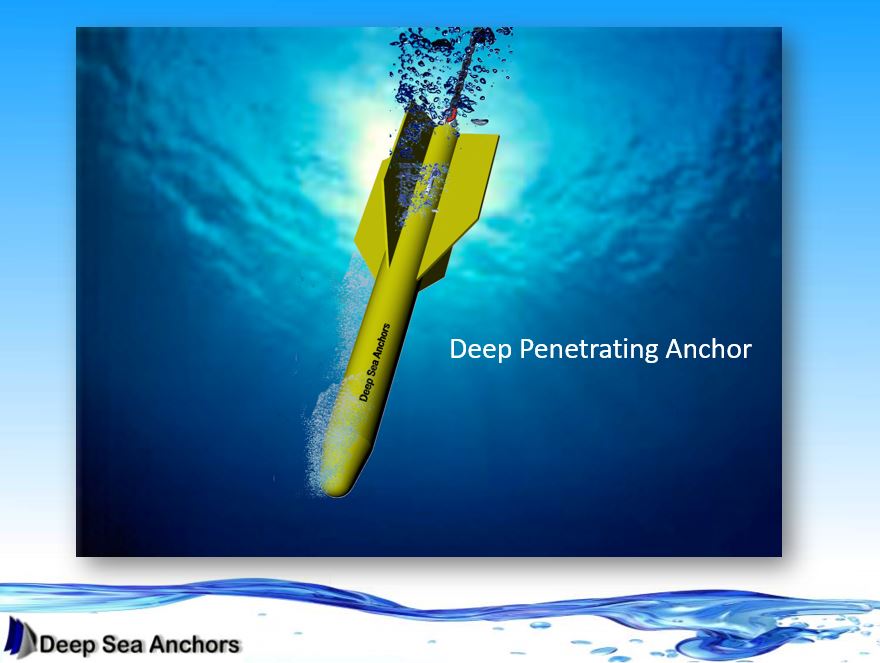

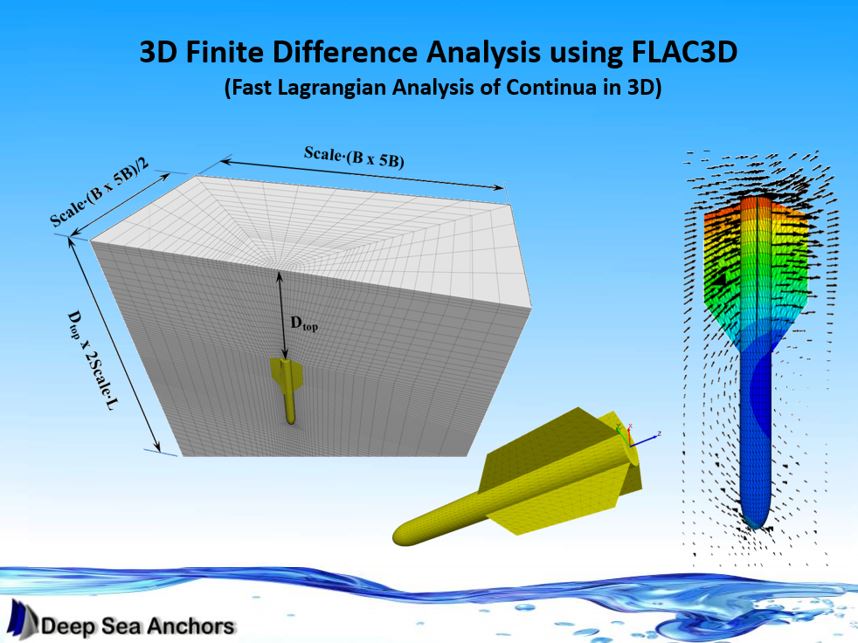

To install a DPA-style anchor, it is first placed in an anchor recovery frame of an anchor handling vessel, before being over boarded and lowered to the correct height above the seabed. During this process, the motion of the anchor is controlled by the hydrostatic stability margin, which is the distance between the anchor’s centre of gravity (CoG) and centre of buoyancy. When the anchor is released, its vertical velocity is near zero, meaning it is in an unstable state and vulnerable to large current forces, which could cause a slight rotational acceleration. In such case, it is important to have adequate separation between the anchor’s CoG and area centroid. If placed correctly, the anchor will be able to reduce the pitch velocity and correct any initial tilt while travelling a relatively short distance. The unique, rounded tip of the DPA creates less rotational resistance during this process and reduces its hydrodynamic resistance to directional changes. This prevents the anchor from slicing through the water phase, making it easier to correct any pitch or yaw.

The height at which an anchor is positioned above the seabed is determined by the size of the anchor. In most instances, the installation height is approximately six times the length of the anchor, which allows the anchor to reach a velocity of approximately 100kph. At this speed, a large amount of kinetic energy is generated to drive the anchor into the seabed. In soft clay sediments, the anchor will sink in deeper, compared to stiff clay, but this does not impact the holding capacity. Using an acoustic release, an anchor will typically penetrate 20m to 30m into the clay sediments to secure floating wind installations with loads of more than 1000 tonns. This process is the same at all water depths. DSA’s anchor technology has been ISO certified and is also qualified in Equinor and approved by Det Norske Veritas.

DPAs are also quicker to install than conventional suction anchors, which can take between six and 12 hours and require the use of large crane vessels. A DPA can be installed using standard anchor handling vessels in most cases and is also less sensitive to weather conditions, providing greater flexibility for installation times.

The type of anchor required often depends on the seabed lithology and DPAs are most suitable for use in cohesive clay sediments. This means that DPAs are ideal for use with floating wind farms, as many potential new farms will be located in deep water areas from 150m to 350m, where clay sediments are commonly found.

Benefits of DPA anchors

Anchor sharing where three mooring lines are connected to one anchor will reduce the number of required anchors in a windmill farm, where suction anchors are the preferred solution. However, this results in substantially bigger anchors since they must take larger loads during a design storm, or if a line break in an accidental limit state condition occurs. In addition, a three-line configuration will prohibit any trawling by the fishing industry in the area due to the relatively short distances between each floating wind turbine. Alternatively, two mooring lines per anchor should allow for trawling, if the seabed infrastructure is arranged appropriately, and considerably reduce the anchor size and mass. A two-line configuration may be handled using DPAs, although this has, at present, not been demonstrated through full scale tests. A paper describing such a wind farm configuration has been published in the journal Ocean Engineering with title: “Dynamically installed anchors for floating offshore wind turbines”, November 2022.

Nevertheless, all wind farms with anchor sharing will have several anchors with only one mooring line attached at the perimeter. Depending on the field size, there may be 30% or more of the total number of anchors. Therefore, DPAs can be used as a cost-cutting alternative to suction anchors.