LEHMANN & MICHELS are providers of diesel, gas, steam and compressor engine condition and performance analysis systems for the marine industry. LEHMANN & MICHELS specialise in engine mean indicated pressure (MIP) systems for performance reporting and condition based maintenance (CBM). The MIP range includes electronic indicators, MIP calculators and permanent computerized MIP systems that enable 24hr engine monitoring to shaft power measuring systems.

LEHMANN & MICHELS’ engine condition and performance analysis systems enable our customers to achieve optimum power and energy use and to enable the customer to carry out CBM combined with planned maintenance (PM).

Engine performance analysis for CBM

LEHMANN & MICHELS’ engine performance experts provide engine performance analysis to achieve better operational reliability and reducing fuel consumption for their customers. By conducting engine performance analyses it is possible to base maintenance and repair costs on hard facts, not just time. LEHMANN & MICHELS’ engine performance analysis paves the way for CBM and provides detailed information about the actual condition of the engine.

PREMET – mobile electronic indicators

PREMET mobile electronic indicators are designed and manufactured for use on diesel and gas applications for the marine market and mobile / stationary power stations and are not affected or restricted by heavy fuel oil. It is possible to measure and record peak of pressure (pmax), course of pressure (p/alpha), maximum increase in pressure (dp/da) and vibration. This data can be used to analyse:

- Indicated power (kW/hp)

- MIP

- Power distribution

- Ignition pressure distribution

- Revolution (rpm)

- Torsional vibration

The PREMET software offers several diagrams to analyse combustion and pressure changes in the cylinders. The data can easily be compressed to quickly send files by email or satellite to the main office.

PREMET online – permanently installed MIP system

LEMAG PREMET online is a permanently installed MIP system developed for measurement of cylinder pressure on diesel and gas engines. It monitors:

- MIP

- Maximum cylinder pressure

- Indicated power (kW/hp)

- Torsional vibration

- Expansion pressure

- Main trend function

In this system each cylinder is equipped with a LEMAG PREMET online pressure sensor. These sensors are attached to the existing indicator valves which all measure the cylinder pressure at the same time. This online information is then transmitted to a central computer for analysis.

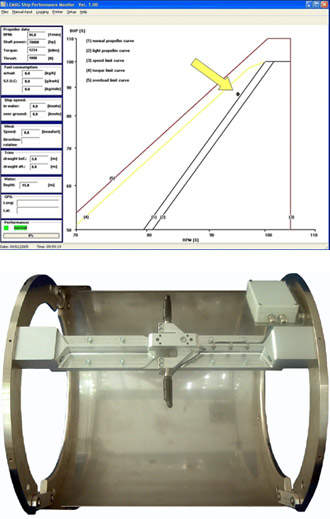

LEMAG Shaftpower – propulsion engine power measurement system

LEMAG Shaftpower is a permanently installed power measurement system that measures the actual power output of the ship’s propulsion engine. LEMAG Shaftpower operates absolutely contact free and does not use strain gauges. The measured power data is displayed in ‘real-time’. Comparing the actual data with the pre-set ‘propeller curve’ helps the operator avoid unintentionally overloading the engine. As an option it is possible to measure fuel consumption, enabling the crew to optimize cruising speed and trim.

LEMAG Slashpol H – fuel-oil homogeniser

The LEMAG Slashpol H homogenizer reduces the size of asphaltenes, creating a consistently fine fuel-oil structure that enables a more stable combustion and can therefore extend equipment life. The system is based on the stator-rotor principle: The conical rotor runs against the stator with only very low clearance but high rotating

speed, creating strong frictional forces that cause the long carbon chains in the fuel to break up.

LEMAG Slashpol E – water-in-fuel (WIF) emulsifier

The LEMAG Slashpol E WIF emulsifier can reduce NOx and particle emissions adding water to the fuel oil. The LEMAG Slashpol E emulsifier creates a homogeneous water in fuel emulsion with a droplet size of max. 5µm, which enables NOx and particle emission reductions across the marine and power station engine’s entire operating range.