Total iron concentration in cylinder drain oil (CDO) is an important parameter to measure regularly in terms of determining the wear condition of two-stroke marine diesel engines, and in particular the wear rate of cylinder components (pistons, piston rings, and cylinder liners).

The surfaces of cylinder components can be subjected to different wear types at the same time:

- Abrasive iron wear caused by mechanical friction between piston ring package and cylinder liner → ferromagnetic iron particles;

- Corrosive iron wear or so-called ‘cold corrosion’ (acid corrosion due to chemical reaction from combustion residues and sulphur present in the fuel oil) → non-magnetic iron salts.

Only the measurement of the total iron concentration (the sum of abrasive and corrosive wear) in CDO samples, in combination with the remaining base number (BN), provides accurate and reliable results for the assessment of cylinder lubrication condition. This is also required in various service letters from leading engine manufacturers.

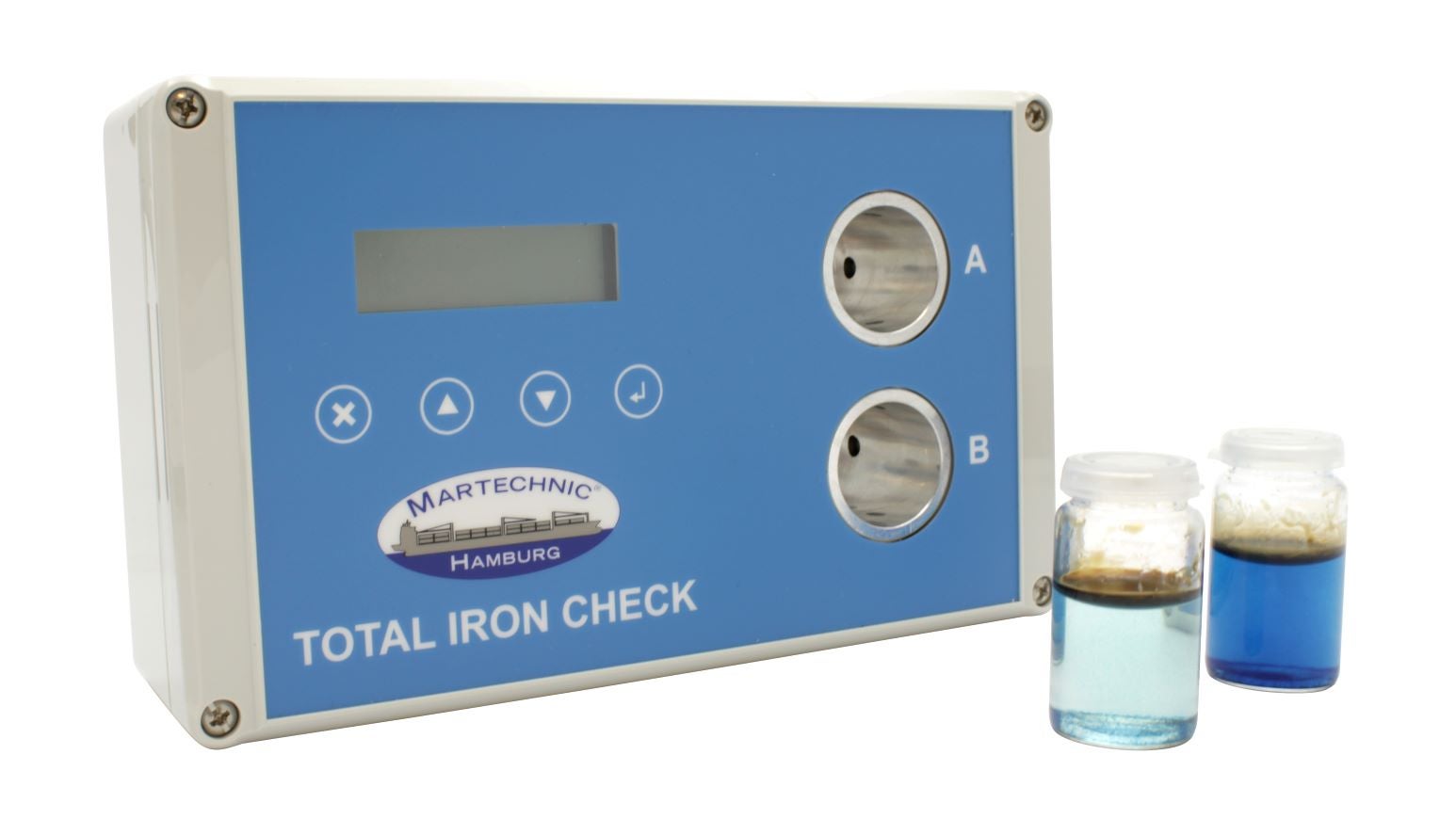

For regular on-board monitoring of total iron content in cylinder drain oil (CDO) samples, Martechnic® has developed the digital test device TOTAL IRON CHECK. Routine analysis with the TOTAL IRON CHECK and its two-chamber measuring system is easy and quick. The glass vials, with special reaction liquid, are pre-heated in the chambers A and/or B of the test device. Then, the CDO sample/samples is/are added to start the automatic measurement of the total iron content. The test device detects and measures all iron particles present in the CDO sample irrespective of their size, including also the large ones. The degree of total iron concentration that can be measured can be ranging up to 1100mg/kg (ppm).

The degree of the measured total iron content can also be visually observed after the test. If any iron is contained in the CDO sample, the chemical reaction between the special reaction liquid and the iron will result in a blue colour change of the liquid. The intensity of the blue colour may vary from light to dark blue and directly depends on actual total iron concentration in the CDO sample

The measured values will be automatically saved on the internal memory chip. The USB to serial connection helps to transfer the test results into a terminal program and further into Excel or similar software for trend analysis.

The TOTAL IRON CHECK enables early identification of unusual measurement values (such as gradual, but constant increase of total iron concentration, as well as high amounts detected). It provides fast information to the engine operator about impeding damages in the engine to take a closer look at the problem and to be able to initiate appropriate countermeasures promptly.

Key benefits of the TOTAL IRON CHECK include:

- Precise semi-automatic measurement of total iron content

- Processing of two samples simultaneously (effective time-saving technique)

- Easy to read, digital display of test results

- Storage of the measured iron values per cylinder with date and time stamps

- Early warning of abnormal wear processes in case of regular application

- Efficient adjustment of lubrication of crosshead engines