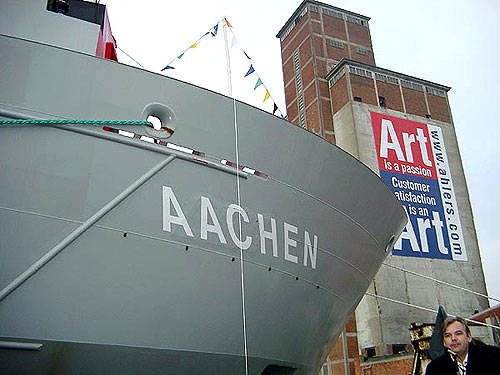

The Aachen was the first of six general cargo container vessels built at the Koninklijke Niestern Sander shipyards for Intersee Shipping in 2004. Designed to sail in Arctic and tropical regions, the vessel has a length of 106.2m. It has a moulded breadth of 14.4m and a draught of 6.14m. It registers 3,930gt and has a displacement of 7,660t.

Construction

In order to enable the vessel to operate in icy areas, the ship has been fabricated with transverse frames, fore and aft. It has a double bottom construction, with longitudinal frames ensuring a 650mm spacing. Crossbeams supported by longitudinal girders stiffen the decks.

The hull is protected from corrosion by epoxy paints and a corrosion control impressed current system. The bunkers include 225m³ of heavy fuel oil, 89m³ of marine diesel, 61m³ of fresh water, 21m³ of

sewage water and 2,778m³ of ballast water.

Cargo capacity

The Aachen has a large deck area of 908m² of covered hatches. The hatch covers can withstand a maximum load of 1.75t/m², which affords the vessel a container capacity of 104 TEU. The movable grain bulkheads and pontoon box type construction covers are handled by means of a Coops & Nieborg travelling deck gantry crane and secured by stainless steel cleats.

The vessel has two holds, mechanically ventilated by two axial flow fans per hold which manage six air changes per hour. Both holds measure 37.53m x 11.7m x 9.8m which gives a total combined capacity of 27,0049ft³.

Engines, generators and manoeuvring

The cargo vessel is powered by a single Mak 9M25 medium speed engine, with an output of 2,700kW at 750rpm. This is directly coupled to a Flender Bruinhof GBCP-710 reduction gearbox and from there, to a Rolls Royce Kamewa controllable pitch propeller.

The four-bladed 94P1/4 propeller has a diameter of 3,400mm. It rotates at a maximum speed of 194rpm, which gives the vessel a sailing speed of around 40 knots.

A Newage Stamford shaft generator with an output of 10kVA at 1,500rpm is also driven by the main engine. Power is also supplied by two auxiliary generator sets located on the port side. These consist of Caterpillar C9DI-TA engines which drive a Leroy Somer generator. They each have an output of 162kVA at 400VAC. There is also an emergency generator on the main deck aft.

Manoeuvring in ports is assisted by a Veth bow thruster. This 350kW bow thruster is based on a 1,200mm-diameter fixed pitch propeller rotating at 1,500rpm, electrically driven by a feed from the shaft generator.

Accommodation, navigation and safety

At the stern of the Aachen is the accommodation and navigation bridge. Accommodation facilities include two crew cabins, cook’s cabin, mess room, galley and a changing store. Safety systems include an Ajax CO2 fire extinguishing system in the cargo hold and engine room. There is also a water mist and seawater sprinkling system located in the stores area and engine room. There is an array of fire detectors and smoke sampling systems in the cargo holds.

A Hatecke 12-man covered freefall lifeboat system and MOB rescue boat and inflatable rafts located port and the starboard are included in the lifesaving appliances.

The ship’s navigational aids and shipboard communications system were supplied by Radio Holland Netherlands.