The 4,864 TEU panamax containership Antwerpen Express was built by Hyundai Heavy Industries in South Korea and delivered to owner Hapag-Lloyd Container Line in April 2000. The owner planned to deploy the vessel on its Far East express routes, conducted with its operating partners, P&O Nedlloyd, NYK, OOCL and MISC, within the framework of the Grand Alliance.

Antwerpen Express is the first in a series of seven panamax containerships under construction for Hapag-Lloyd at Hyundai. Of the subsequent six newbuildings, three are owned by Hapag-Lloyd, while the other three will be chartered from Greek owner Costamare Shipping.

Antwerpen Express flies the German flag and has Germanischer Lloyd classification.

DESIGN

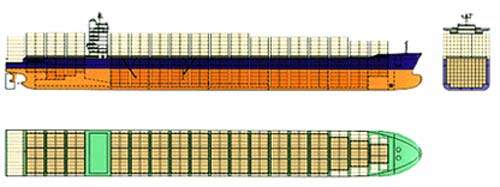

In common with the earlier series of eleven containerships led by Hannover Express, Antwerpen Express has panamax main dimensions of 294m overall length, 32.2m moulded breadth and a maximum draught of about 13.5m.

Improvements in engine design from MAN B&W enabled Antwerpen Express’ naval architects to gain extra cargo space within the given hull envelope. Hannover Express had a cargo capacity of about 4,600, compared to Antwerpen Express’ greater capacity of 4,864 TEU. This increase derives in part, about 70 TEU, from the change in engine design. In addition, an extra bay of containers has also been gained by the construction of a shorter accommodation block.

Antwerpen Express’ cargo arrangements comprise six cellular cargo holds, five of which are arranged forward of the superstructure and engine room, with the sixth positioned aft. Being of the so-called ‘girderless’ type, the underdeck area has been optimised for container stowage, to give a maximum of eleven rows and eight tiers of TEU in the hold spaces in the parallel body. The beam also allows an upper deck stow of 13 rows of boxes.

Hyundai, the builder of the vessel, has put the vessel’s maximum capacity at 4,890 TEU. Of this, 2,326 TEU can be stowed in the holds and 2,564 TEU can be accommodated on the weatherdeck and pontoon type hatch covers. 350 sockets are available for the transport of reefer containers.

PROPULSION

Antwerpen Express has been fitted with a seven-cylinder MAN B&W two-stroke K98MC engine. The engine was developed by MAN B&W in Denmark and its twelve-cylinder 93,360bhp configuration has been chosen by Hapag-Lloyd for its 7,200 TEU series of containerships under construction at Hyundai.

The earlier series of Hannover Express class containerships were fitted with the K90MC engine, which was the widest two-stroke machinery at the time of ordering. The greater power density of the K98MC has enabled Antwerpen Express’ power needs to be met with two cylinders less than the nine cylinders used in these preceding vessels.

The 9K90MC installation in each of the Hannover Express sisters delivers 55,980bhp at 94rpm, at a mean effective pressure of 18bar, whereas the seven-cylinder examples for the Antwerpen Express series turn out 54,460bhp at the crankshaft speed, on 18.2bar. The slight reduction in maximum power was regarded as acceptable on the basis of the speed performance of the vessels already in operation.

The 7K98MC engine is supercharged by three units of the TPL85-B11 turbo charger design developed by ABB Turbo Systems based in Switzerland, providing one of the first applications for the new TBL-B generation, tailor-made for two-stroke machinery.

The vessel is equipped with a STN Atlas navigation and command system (Nacos).