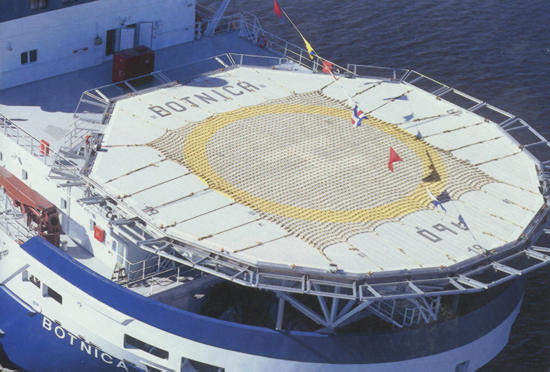

The Botnica, a huge, 6,370gt combined icebreaker, tug and supply vessel, is widely considered by the offshore industry to be the most advanced state-of-the-art vessel of her type. She was built at Aker Finnyards in Finland to Det Norske Veritas class standards, and delivered in 1998 to the Finnish Maritime Administration (FMA).

Botnica is the third in a series of multipurpose vessels built at the yard and was completed in just 13 months. She was being deployed in Norwegian waters during her first northern hemisphere summer under a seven-year charter with options for extensions.

During her first year, she was also under a contract with Saga Petroleum on subsea well intervention duties in the Vigdis field in the North Sea. In the winter months she returns to her main task as an icebreaker keeping southern Finland’s waterways and coastlines open to commercial traffic.

The FMA operates a fleet of nine icebreakers. Up to 80% of Finland’s trade is handled through its seaports and 50% of this is handled during the winter months.

Propulsion

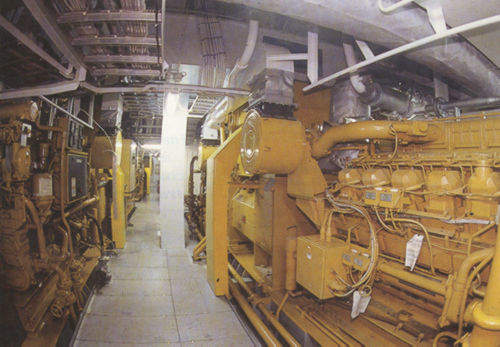

The main difference between Botnica and her predecessors, the Fennica and Nordica, is the propulsion method employed. Both her sisterships used Wrtsil medium-speed diesels as their main propulsion plants. However, for its most recent vessel, the FMA decided on an ‘engine-generator-engine’ diesel electric plant. This comprises six packages of twin Caterpillar 3512B units, giving a total output for the twelve engines at 12MW.

The six packages are twin Caterpillar V12, four stroke 51.8l design, and are connected to six ABB generators powering a Megastar controlled thruster system of two 5MW Azipods.

The thrusters can be used to create a propeller wave that pushes broken ice away from the hull and creates a wider channel for the following convoy of commercial merchant vessels. This is the first application in the world for this type of engine generator package.

The excellent seakeeping and stability required from a satellite-controlled, dynamically positioned exploration drilling vessel would, therefore, seem to be at odds with the sort of hull design adopted for the Botnica.

Yet the new package, developed and patented by the FMA, appears to have achieved an unusually high performance level. It can use the maximum power needed for a front line icebreaker, without the economic and environmental downside of running a massive slow-speed engine at virtually idle power for offshore standby or positioning duties.

By employing a 92% efficient diesel electric system and housing the propulsion motors in the Azipod units themselves, significant weight, space and maintenance penalties associated with larger, slower-speed engines, gearboxes and drive shaft systems have been eliminated. This multipack approach has also ensured that the vessel has two fully watertight and capable engine rooms, an essential feature for arctic operations.

Design

According to the FMA, the classic icebreaker design generates its performance from the fore section of the hull, while an offshore vessel is exceptionally stable because of its aft characteristics. Botnica combines both of these elements in a new hull design, featuring stability tanks.

The power arrangements are part of a revolutionary concept designed by senior engineers and naval architects at the FMA. The classic icebreaker action of riding up on the ice before slamming down in a dynamic side to side motion is well proven.

However, this is a hull induced action that tends to make the vessel extremely uncomfortable for those on-board with excessive shuddering and twisting. It also makes the vessel relatively unstable in open water. Thus, for most icebreakers, their operation is usually limited to eight months of the year and they are unable to manage additional, lucrative work in the offshore spot market.