The Chikyu is a scientific drillship which was designed to operate in water depths in excess of 2,500m. It incorporates a range of facilities that enable it to drill up to 7,000m below the sea bed. This makes it one of the world’s deepest drilling vessels. By comparison, the US deep-sea research ship Joides Resolution achieved a hole of 2111m.

Its mission is to drill into the tectonic plates and potentially into the earth’s mantle. It is anticipated that research will play an important role in understanding the principles of tectonic movement and earthquake prediction.

Chikyu means ‘Earth’ in Japanese. It was built by Mitsubishi Heavy Industries for the Japanese Agency for Marine Earth Science and Technology (JAMSTEC).

The Chikyu was delivered to its owners in 2005, but since then it has been carrying out a range of system integration tests. These were followed by a shakedown cruise, which involved test drilling off the Shimokita Peninsula to ensure that everything was working satisfactorily before it commenced full operations in 2007.

In March 2011, the ship was damaged by the earthquake and tsunami in Japan. It was repaired at Shingū, Wakayama dock and returned for service in June 2011.

Design

In May 2009, the vessel embarked on a 319 NanTroSEIZE Stage 2 expedition in Nankai Trough, Japan. It completed the riser drilling operations in August 2009. The expedition prepared boreholes at two sites to be used for future installations of the long-term borehole monitoring systems.

At the first site in the Kumano Basin (Site C0009), riser drilling and casing operations proceeded approximately 1,600m beneath the seafloor. Also, hole conditions were assessed through LWD/MWD (logging while drilling/measuring while drilling) and wireline logging. Spot coring and downhole measurements were also taken up.

The drillpipe, riser and casing are stored in the pipe rack which is located next to the V-door. They enter the derrick by an automated pipe transfer system. This is based on a rail-mounted Hydratracker. Once the pipes are introduced and stored in the derrick, an iron roughneck is then used to connect them onto the drillstring.

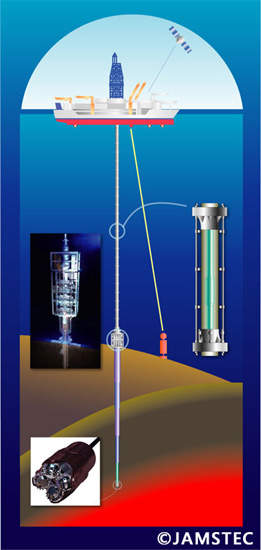

Drilling is carried out by means of a top drive system. The drillstring enters the water through a 12m by 22m moonpool. In order to allow for the vertical and lateral movement of the drillship in the ocean, the ship includes a crown-mounted heave compensator.

When drilling, to prevent reservoir pressure suddenly forcing its way back up the drillpipe, there is a blowout preventer system. This weighs 380t, stands 14.5m high and can withstand a pressure of 103MPa. Because of the water depths, the drillship has a riser drilling and a riserless drilling option.

To facilitate well operations, there is an electric hydraulic knuckle boom crane system. Its principal operation is to load and unload stores from the support vessels, mainly the drill pipe, casing and other tubulars.

Propulsion

The main propulsion is by a series of thrusters, which are also responsible for the dynamic positioning that is fundamental to deep water operations. These enable the drillship to maintain position in conditions of up to 23m/s wind speeds, a surface current of 3–4 knots and wave heights of up to 4.5m.

The system includes a 2550kW tunnel thruster in the bow, three 4100kW thrusters located forward and another three 4100kW thrusters aft. The diameter of the thruster propellers is 3.8m. This also gives a 12 knot cruising speed and gives the ship a range of around 14,800 nautical miles (full load condition, 10 knots).

The power is provided by six generators with an output of 5000kW each. There are also two auxiliary generators with an output of 2,500kW each.

Technology, research and operations control

Chikyu uses the riser drilling system for conducting upstream oil and gas industry activities. The equipment and material include a riser pipe, drill pipe, downhole measurement tools and devices, and an artificial drilling vessel. In addition, a blow out preventer ensures safe drilling in unexpected high pressure flows of oil and gas and other fluids from the well.

The vessel has onboard research facilities such as borehole observation, microbiological analysis, sampling processes, testing laboratories and long-term downhole monitoring systems.

Chikyu controls its drilling activities by using GPS positioning data from satellites and an acoustic positioning system in communicating with the transponders on the ocean floor. The data gained from this system is used to position the vessel based on the direction and speed predictions. A 50cm diameter pipe, with 3cm-thick walls, stretches from the ship to the seabed.

Expeditions

In May 2009, the vessel embarked on a two-month 319 NanTroSEIZE Stage 2 expedition in Nankai Trough, Japan. The expedition will prepare boreholes at two sites to be used for future installations of the long-term borehole monitoring systems.

At the first site in the Kumano Basin (Site NT2-11), riser drilling and casing operations will proceed approximately 1,600m beneath the seafloor. Also, hole coditions will be assessed through LWD/MWD (logging while drilling/measuring while drilling) and wireline logging. Spot coring and downhole measurements will also be taken up.

At the second site, C0010 (near C0004), riserless drilling and casing was driven to 555m, with LWD.

Future expeditions included the 322 NanTroSEIZE Stage 2 ‘Subduction Input’, which was completed in October 2009. It characterised composition, architecture and state of pre-subduction sediments transported to the seismigenic zone. Proposed site NT1-07 witnessed coring, logging and downhole measurements at 1,200m below the seafloor. The contingency site NT1-0, with a target depth of 600m, involved coring. The drilling site was located at a depth of 4,000m.