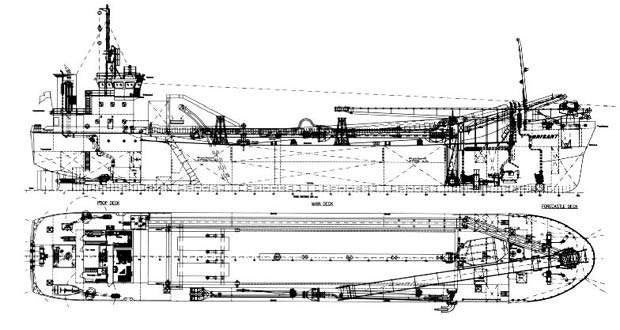

The Orisant trailing suction hopper dredger was built at the Barkmeijer Stroobos shipyard for the Dutch company Zand- en Grind Exploitatie Maatschappij Orisant BV. The vessel has an overall length of 89.2m and a length between perpendiculars of 85m. Its breadth is 14m and it has a 6.6m draught. It can dredge at a depth of 35m and attains a speed of 13 knots. Its main operational area is the North Sea coast. A key feature of the dredger is its self-unloading facility, unique for such a type of vessel.

DREDGING PUMP

The pump room is located in the front of the hopper. It contains a double-walled dredging pump with a capacity of around 10,000m³/h water. This is driven through a Caterpillar of 1,120kW engine. A reduction gear system is located between engine and pump. This includes a power take off of approximately 600kW, which is used for a hydraulic pump. To handle heavy parts into, or out of, the pump room, the foremast can be used as a small crane.

At the end of the pump is an 800mm diameter suction pipe through which the sand and material passes. The material is then discharged into a sieve system, which is used to separate the grain size of the aggregate into sand and coarser materials. In order to ensure sufficient flow, water is injected with high pressure at a number of locations as the mixture then flows to the centre of the hopper. At the bottom of the hopper, two drain gutters extract the water of the dredged mixture. Driven by a 474kW engine, the jet pump can also be used to fill up the midships fresh water tanks. There is also a second, 120kW auxiliary engine in the pump room.

DREDGING AT SEA

When dredging at sea the vessel could be required to deliver sand that is flushed with fresh water. The vessel is consequently equipped with two freshwater tanks for washing the sand and/or gravel at sea when the hopper is filled up.

A specially-designed, self-supported, remote controlled system is used for discharging the sand or gravel out of the hopper. The fully automatic self-unloader is supplied by Stokman.

The mechanism, based on two belts, rides over the hopper and discharges its sand or gravel on a conveyor belt. The material is then passed onto a 38m intermediate and shore conveyor. The shore conveyor can be rotated over an angle of 270°. It is then discharged ashore, at a rate of approximately 2,000m³/h, allowing the hopper to be unloaded in approximately 1.5 hours.

POWER, PROPULSION AND CONTROL

The ship is propelled by a Caterpillar marine diesel engine, driving a five-blade, fixed-pitch propeller in a tunnel shaped emplacement. This is connected via a reverse reduction gearbox and a trolling system. It is capable of developing 2,250kW of power.

Electric power is delivered from one auxiliary generator of 145kW placed in the engine room and one auxiliary generator in the pump room.

Manoeuvring is enabled by a Veth jet-type bow thruster driven by a 474kW marine type diesel engine which is located in order to provide movement in three directions, as well as being used for propulsion in an emergency.

Both the main engine and the dredging operation and navigation can be controlled from the integrated bridge system. Video cameras are located at several positions around the ship to provide all necessary information.

The accommodation of the vessel has been arranged in a superstructure aft and includes eight cabins.

The Orisant is built in accordance with the latest IMO safety regulations and under Bureau Veritas Classification.