The CCNI Potrerillos is designed to carry containers, as well as metal, wood products and bulk products such as grain and minerals. The vessel was built by Stocznia Szczecinska of Szczecin, Poland, and is part of the fleet of tankers operated by CCNI (Compania Chilena de Navegacion Interoceanica SA) of Chile.

DESIGN

The CCNI Potrerillos has an overall length of 185m, a design draught of 12m and a moulded breadth of 32.2m. It has a deadweight of 45,000dwt. The bulker is a transom type structure with a bulbous bow. It has a double bottom extending from the forepeak to the afterpeak bulkhead. The bottom skins have been strengthened by longitudinal framing, and the forward area has been reinforced to counter the slamming effect of the water. The side construction is also double-skinned.

The CCNI Potrerillos has a maximum container capacity of 1,830 TEU. This is divided into 922 TEU, which can be carried in the holds, and 908 TEU on the main deck as well as on the hatch covers. Containers are stored in holds 1, 3, 6 and 8. Holds 2, 4, 5 and 7 have a grain-carrying capacity of over 27,000m³. In front of the superstructure, a stack load of 60t/TEU or 90t/TEU, or a uniform load of 3t/m can be supported by the main deck.

Tanks in the afterpeak and forepeak areas combine with the side tanks to provide the necessary ballast areas. The ballast water capacity totals 18,400m³. The ballast pumping facilities have been supplied by the Danish company, IRON. The bulker can de-ballast in eight hours. There are eight hatches with steel hatch covers manufactured by Fugo Konin, the MacGregor licensee in Poland. Four of the covers (hatches 1, 3, 6 and 8) have an open web-construction and a lift-away type. The covers on the others are double-skinned and pivot by means of hydraulic cylinders that are fitted to the hinges.

There are three Towimor hook-type cranes on deck. These have a 40t lift capacity and a 28m outreach. For 20ft containers, it can attain a 32m outreach.

PROPULSION

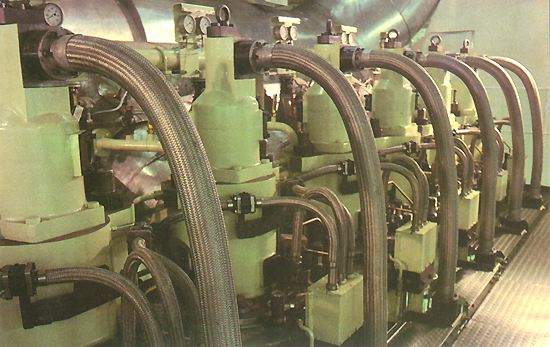

The CCNI Potrerillos is driven by a Cegielski/Sulzer 6RTA58T main diesel engine which was built by HCP, the Sulzer licensee in Poland. The six-cylinder engine provides an output of 11,400kW (15,280bhp) at 101.5rpm. This drives a single, fixed-pitch, bronze, four-bladed ABB Zamech propeller. The Ulstein Frydenbo electrohydraulic steering system is a rotary vane system leading to a partially balanced rudder. The engine room equipment also includes electrically driven centrifugal seawater, fresh water, ballast and bilge pumps.

Also located in the engine room are two Aalborg boilers. The auxiliary boiler is designed to burn 600cSt (at 50°C) heavy fuel oil. It has a capacity of approximately 2,800kg/h and a 0.7MPa steam pressure. The second boiler is a forced circulation exhaust gas boiler system. This has capacity of 1,500kg/h at 85% MCR. Electric power is afforded by three Cegielski/Sulzer 6S20UH main diesel gensets. Each of these has a rated output of 960kW at 900rpm.

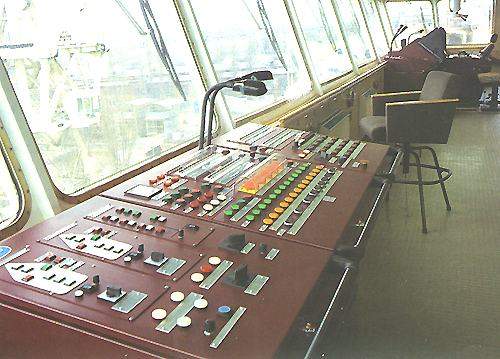

AUTOMATION AND CONTROL

The engine room is arranged with a control and monitoring system, that meets LR class requirements for a periodically unmanned engine room. Stein & Sohn of Germany supplied the main engine control system, as well as its Camos 2000 engine-room alarm and monitoring system.

The CCNI Potrerillos is equipped with GMDSS compliant equipment. The 600WMF/HF radio station is supplied by Sperry, and there are two DSC VHF radiotelephone sets. Amongst the navigational aids on-board the CCNI Potrerillos are two Sperry navigation radars, a Sperry speed log, a Raytheon-Anschutz gyrocompass and an Allied Signal/Elac echosounder.