The Stena Perros is a P-MAX tanker ordered by Concordia Maritime AB as part of a ten-ship contract with the Croatian shipyard Brodosplit.

The Perros was delivered from the shipyard in December 2007 and has been signed for a five-year charter with the French oil company Total for the transportation of refined oil products.

MAX CONCEPT

The MAX concept means that the vessels have been designed to undertake their maximum loading capacity in shallow waters.

In addition, they were designed for safer oil transportation with double main engines in two completely separate engine rooms, double rudders, double skin and steering gear, two propellers and double control systems.

The redundancy and back-up systems in this vessel design means that they are some of the safest tankers afloat.

P-MAX TANKER SPECIFICATIONS

The Perros has a length of 182.9m, a breadth of 40m, a design draft of 11.3m, scantling draft of 13.0m and moulded depth 17.9m. Cargo volume is 70,200m³ (maximum) and the width of the double skin is 2.0m–2.1m. The vessel has a gross tonnage of 36,000t.

These Perros has been built with an ice class 1B specification (to negotiate moderately difficult ice conditions). The ship also has provision for 2,000m³ of heavy fuel oil, 360m³ of freshwater and 26,200m³ of water ballasting when required.

ENGINES

Two B&W 6S46MC-C engines produce 7,860kW each at a speed of 129rpm.

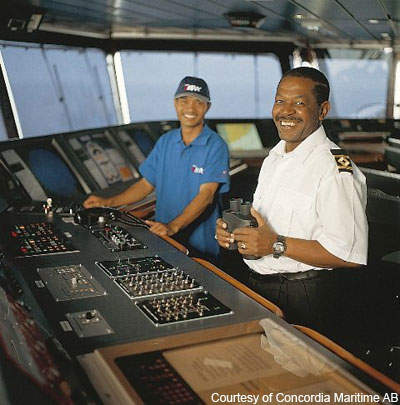

The Perros’ navigation system is designated NAUT-AW and is equipped with automatic grounding avoidance (the vessel will operate in shallow waters at maximum loading so this is vital). There is also a fully integrated bridge layout to allow safe navigation in narrow channels.

CARGO HOLDS

There are five pairs of epoxy-coated cargo tanks along with two slop tanks. The tank cleaning system is a single-nozzle programmable automatic system (allowing quick changeover from dirty to clean products) and tank heating is carried out using stainless steel steam heat exchanger coils (SS SUS316L).