Tasik Toba is a subsea operation vessel (SOV) being built by Mawei Shipbuilding Company at Fujian Mawei Shipyard on Culu Island in China, for Singapore-based SOV developer Tasik Subsea.

It is the first DP3 vessel designed by the company that could support a larger crane, deepwater operations and saturation diving.

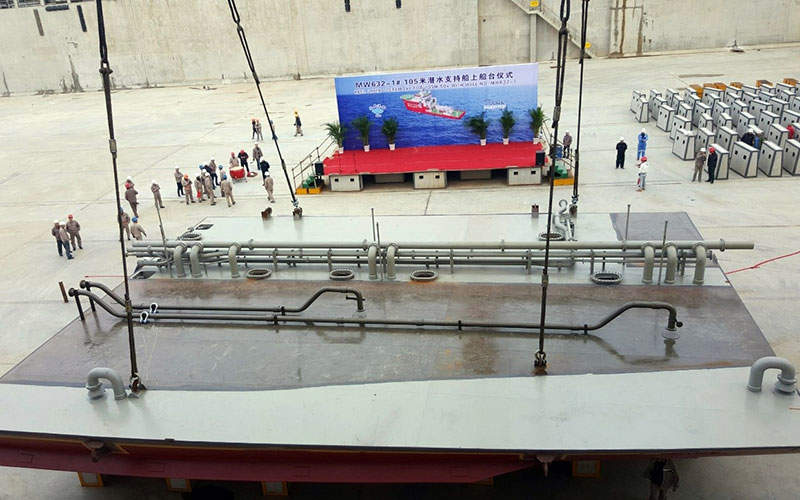

Construction of the vessel began in August 2014 followed by the first steel cut in August 2015 and keel laying in December 2015. The vessel is scheduled to be delivered in the first quarter of 2017.

Tasik Toba SOV design and features

Mawei Shipbuilding Company has worked with selected naval architects and engineers to design and develop a new class of SOV. The vessel will have a deck space of 1,000m² with strength up to 10t/m². It will feature a 150t subsea crane and a 22.2m diameter helideck that will enable fast transfer of crew and operating staff.

It is classified as ABS A1(E) Offshore Support Vessel, (DSV SAT, ROV, SPS), ACC, ENVIRO, GP, and DPS-3 BWT UWILD.

It will have an overall length of 105m, moulded breadth of 24m, depth to main deck of 9m, draft of 6.5m, and length of 96.6m between perpendiculars. It will have deadweight exceeding 4,500t and will operate at a speed of 12k.

The vessel will bear the Marshall Islands flag and will be capable of installing inspection, repair and maintenance (IRM) equipment, inspection, repair, replacement and maintenance (IRRM) equipment and SURF equipment.

It will also support light and medium construction, deepwater intervention, saturation and air diving, and full dual remotely operated underwater vehicle (ROV) operations.

Accommodation

The SOV will have a capacity to accommodate approximately 120 personnel. It will feature 42 twin cabins, 25 single cabins, 11 suites with day and bed rooms, and one hospital with two beds and one treatment room. All the cabins will be fully air-conditioned and feature an attached washroom.

Other facilities on the vessel will include four office rooms, two conference rooms, prayer room, gymnasium, smoking room, two recreation rooms and two laundry rooms.

Tank capacities

Tasik Tabo will have dedicated storage tanks for carrying 4,000m³ of ballast water, 2,000m³ of fuel oil, 900m³ of potable water and 230m³ of dry bulk.

Equipment aboard the SOV

Tasik Tabo will be fitted with five cranes, a main offshore crane, two working cranes and two stores cranes. The main crane will be a MacGregor 150t SWL AP2C1 active heave compensated (AHC), electro hydraulic crane capable of operating in 3,000m water depth. It will have a lifting capacity of 150t at 11.5m, hook travel distance of 3,000m, whipline of 25t at 35m, and a 1.5t man riding function.

The two working cranes will have a lifting capacity of 10t at 10m and a hook travel distance of 3,000m. The two stores cranes will have a lifting capacity of 10t at 10m with a working radius of minimum 4.7m and maximum 18.5m.

The ROV support system will feature facilities to support client’s choice of ROV and ROV launch and recovery system (LARS), a dedicated ROV hangar, control room, tech space workshop and redundant power supplies.

The SOV will feature an in-built, ABS Class / IMCA-compliant saturation diving system with a capacity of 15 men and a depth rating of 300m. It will feature one three-man insulated and positively buoyant bell, a PH hydraulic bell LARS, three six-man DDCs, gas storage of 19,712m³ and other equipment.

The vessel will also have an air-diving system with two stations with DDC, dedicated LARS and dive control.

Propulsion machinery

The SOV will be fitted with four main diesel engines, one 199kW generator, two 2,500kW Voith Schneider main propellers, one 1,999kW azimuth bow thruster, two CPP tunnel thrusters, and two emergency generators.

Navigation systems

Kongsberg will supply its K-POS DP 22+ and K-POS DP-12BU dynamic positioning systems (DPS) for the vessel. Position reference systems will include two differential global positioning systems (DGPS), two HiPAP systems and two lightweight taut wires. It will also feature a sensor system comprising three gyro compasses, three motion reference units (MRU), and three wind sensors.