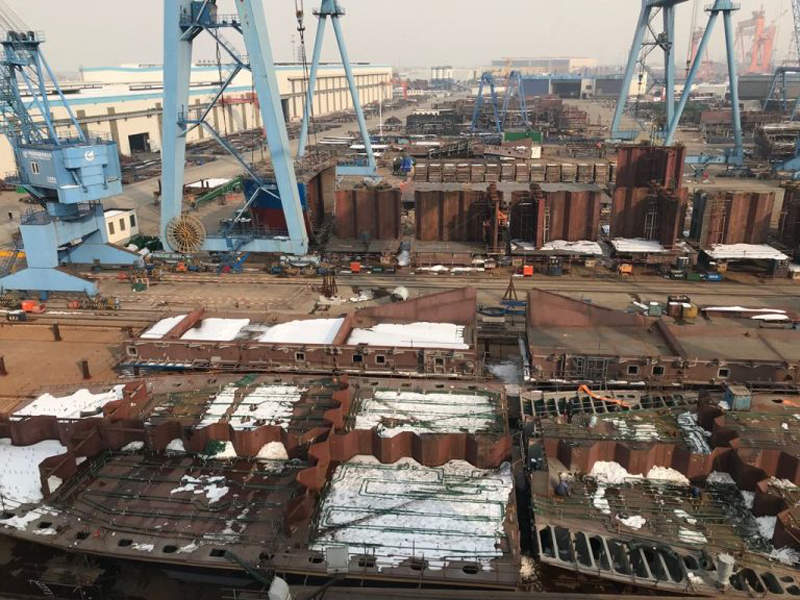

The EVOLUTION-class 7,999dwt oil / chemical tankers are being built by AVIC Dingheng Shipyard for Sweden-based Sirius Shipping.

Development of the EVOLUTION-class began in 2012, with design provided by Sirius and FKAB.

Two EVOLUTION-class vessels were ordered in September 2016 and the keel-laying ceremony of the first vessel, hull number AD0030, was held in February 2018.

EVOLUTION-class oil / chemical tankers design details

The EVOLUTION-class incorporates an optimised hull form to provide low maintenance and fuel consumption, as well as high performance in rough weather conditions.

Each tanker will have an overall length of 119.9m, breadth of 19.4m and draught of 5.5m. The vessels will comply with the Tier III rules and regulations.

It will be able to accommodate up to 16 crew members in 14 cabins and will also feature a fitness room and treatment room. The main operational equipment will be located in enclosed areas, which enables efficient maintenance and operation.

It will also be equipped with two ballast pumps with a rated capacity of 500m³/h each.

Cargo capacities of the EVOLUTION-class tankers

The cargo storage area will be divided into 11 cargo tanks and two slop water tanks. The combined storage capacity of the cargo tanks will be 9,774m³, while the slop pumps will have a total storage volume of 145m³.

The FRAMO submerged centrifugal type cargo pumps aboard the tanker will be made of acid-resistant (AISI 316L) stainless steel. Each cargo pump will offer a transfer capacity of 330m³/h, while the slop pumps will have the transfer rate of 100m³/h each. All six cargo pumps can be operated at the same time if required.

The capacity of heating coils for cargo tank heating will rise from 44°C to 66°C in 96 hours.

The tanker will also be equipped with a stripping system and a super stripping system.

Sustainable features

The tankers will be built with major emphasis on the environmental factors including low-friction hull design, lower NOx emissions below 2g/kWh for ME and auxiliary engines, bio-type products for lube and grease, propulsion redundancy, lower CO2 emissions, and two-stroke propulsion with low losses.

Additionally, the main engine, deck strength, and stability of the vessel are compatible with the installation of two 200m³ LNG type-C tanks for LNG-powered operations.

Engines and propulsion of EVOLUTION-class tankers

The tanker will be equipped with a MAN B&W 6S35ME-B main engine, which will produce a maximum power output of 4,500kW at 144rpm. The engine will be installed with high-pressure selective catalytic reduction system (HPSCR).

The vessel will also feature three Mitsubishi S6R MPTA six-cylinder auxiliary diesel engines, which have a rated power of 610kW.

The SAM 600kW shaft generator aboard the vessel will operate in parallel with auxiliary generators.

A Brunvoll 800kW transversal and retractable azimuth-type controllable pitch bow thruster powered by electric motor will be installed aboard the tanker for manoeuvering, propulsion redundancy and alternative propulsion class notation.

The vessel will also feature Rolls Royce PROMAS-system integrating a rudder and a controllable pitch propeller (CPP). The four-blade high skew type, bronze CPP will have a diameter of 4,400mm.

The tanker will also integrate two 1,500kW thermal oil-type main boilers fuelled by marine gas oil (MGO) and heavy fuel oil (HFO), as well as an exhaust boiler.

The propulsion system will enable the tanker to sail at a maximum speed of 14.3k.