Ballast Water Monitoring

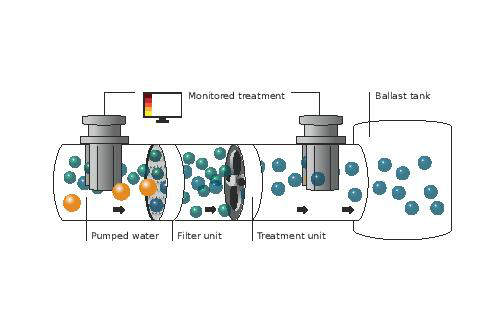

Solutions for Monitoring Ballast Water Treatment Systems

Ballast Water Monitoring develops real-time performance monitors for ballast water treatment systems (BWTS) on-board ships.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Ballast Water Monitoring develops real-time performance monitors for ballast water treatment systems (BWTS) on-board ships.

With our bw-monitor, you get in-line, timely performance data for your BWTS.

Performance monitoring in environment and shipping

BWTS and ballast water management systems (BWMS) are costly and their performance can vary, making continuous monitoring essential for accurate analysis of shipping performance .

The bw-monitor automatically and continuously surveys the functionality and efficacy of your BWMS directly in the ballast. Simultaneously, it monitors the ballasting process during treatment so you can make quick and appropriate adjustments.

Universal monitoring solution for BWTS systems

The bw-monitor can be permanently installed on ships to measure and report on the performance of filters and disinfection units.

The system automatically adapts to the characteristics of incoming water, and instantly provides status notifications to BWMS operators. The monitoring technology works with most systems and can be adjusted to meet your specifications.

Easy-to install, cost-effective ballast water monitoring

The bw-monitor has passed environmental tests in International Maritime Organization (IMO) G8 and US Coast Guard (USCG) land-based full-scale facilities, as well as on-board vessels.

The easy-to-install monitoring system comprises two stainless-steel sensor units, a control unit in an IP65 cabinet, and a display unit with a simple user interface.

Sensors are fitted with DN150 flanges and easily mounted on prepared studs in the ballast line, so they can be operated in just a few hours. The bw-monitor is completely automatic, minimizes the use of energy and consumables, and does not require any interaction from crew members.

Indicative D-2 compliance data for BWTS systems

The bw-monitor uses laser and fluorescence technology to provide performance data on filter efficacy and immediate kill rates, based on your specific BWMS criteria.

Although the bw-monitor is not a port state control system for D-2 compliance it can be modified to provide the data used to assess indicative compliance with International Maritime Organization IMO standards. The bw-monitor can be used to assess treated water on discharge, or installed in a sideline used for monitoring equipment – whatever is most compatible with your BWMS’ design.

Logging and transmitting data

The bw-monitor logs real-time data and provides secure indicative compliance data reports for clients and port state control operators. It also supplies BWMS performance data directly to the ship owner via the internet. Data can be shared with the BWMS manufacturer for improvement or guarantee purposes, without requiring input from the crew.

The solution can be accessed remotely for software modifications and algorithm updates. All data traffic is protected by end-to-end encryption and transmitted in compressed packages.

Contact Details

Website

Email Address

Address

DK 2800 Lyngby,

Copenhagen,

Denmark