AI is the headline of 2025, but it’s the data story underneath that will determine how far the maritime industry can take it, writes Denis Morais, CEO at SSI.

The next 12 months will see a meaningful and measurable advance in how AI is applied within ship design and construction. There’s a lot of excitement around AI and rightly so. But as with many transformative technologies, we tend to overestimate its short-term impact and underestimate its long-term potential.

AI will move faster than previous waves of tech adoption, but its true value will unfold over time as the industry adapts.

Shipbuilding is inherently complex, and while we generate vast amounts of data, much of it is fragmented, spread across spreadsheets, custom databases and disconnected tools. For AI to deliver real value, we need to invest in structuring and connecting that data in scalable ways. That’s not just a technical challenge; it’s a cultural and operational one.

In the near term there are significant opportunity in planning and scheduling, areas rich with structured data and ripe for optimization. AI can help us make better decisions faster, whether it’s sequencing work more efficiently or predicting bottlenecks before they occur.

Maintenance, repair and overhaul are other obvious areas for its application. Image-based AI, already proven in fields like healthcare, can be trained on historical vessel imagery to identify issues like premature cracking or corrosion. The data is available, the models are maturing, and the ROI is clear with faster diagnostics, fewer surprises, and safer vessels.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

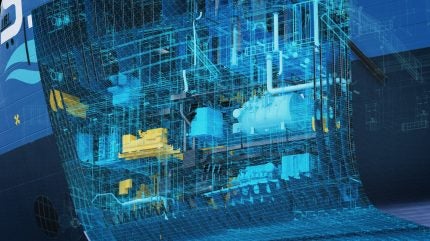

By GlobalDataAI will play a role in design and modeling such as functional, detail, and even generative design. But to get there, we need to lay the groundwork now by improving how we capture, structure, and share data across the lifecycle of a vessel.

Challenging the established order

One perspective that’s often overlooked is how AI will reshape the relationship between shipyards and classification societies. As AI begins to assist in design validation and compliance checking, we’ll need to rethink how rules are interpreted, verified and applied. That shift won’t happen overnight, but it will fundamentally change how we collaborate across the industry.

Another is the role AI can play in bridging the gap between engineering intent and operational reality. Shipbuilding is full of assumptions made early in the design phase that ripple through construction and into service.

AI has the potential to surface those assumptions, test them against real-world outcomes, and help teams make better decisions earlier in the process. That feedback loop is something the industry has struggled to close, and AI could be the key to making it practical.

The last major impact is how AI is changing the economics of experimentation. In the past, testing a new idea in shipbuilding could be expensive and time consuming. With AI, the cost of running simulations, analyzing historical data, or prototyping new workflows is dramatically lower.

That shift allows shipyards to explore more options, fail faster, and iterate more intelligently. It’s not just about spending to save, it’s about spending to learn, and that’s a mindset change we’re starting to see across the industry.

Managing expectations

We’ve never seen shipyards more open to investing in technology than they are right now, particularly when it comes to AI. There’s a growing recognition that the cost of not investing is starting to outweigh the cost of adoption. The industry has always been cautious, and for good reason, but the conversation has moved from “should we spend” to “where should we spend?”

What’s different this time is the speed of decision-making. Shipyards are not only allocating budgets for AI related initiatives, they’re also moving faster to test and validate ideas. Many are partnering with specialists to run focused pilots, not necessarily with the expectation of immediate transformation, but to understand what’s possible and where the value lies.

That said, we need to be focused and disciplined. There will be wins, and there will be missteps. AI is not a magic wand. Like any technology, its success depends on how well it’s aligned with real business problems. The most impactful projects are those that start with a clear understanding of the challenge and a realistic view of how AI can help solve it.

Let’s not overstate where we are. Shipbuilding is still in the early stages of grasping AI’s full potential. There’s excitement, but also a need for discipline and clarity. The challenge isn’t just technical, it’s about aligning people, processes, and data so that AI can be applied meaningfully. Our job is laying that groundwork.