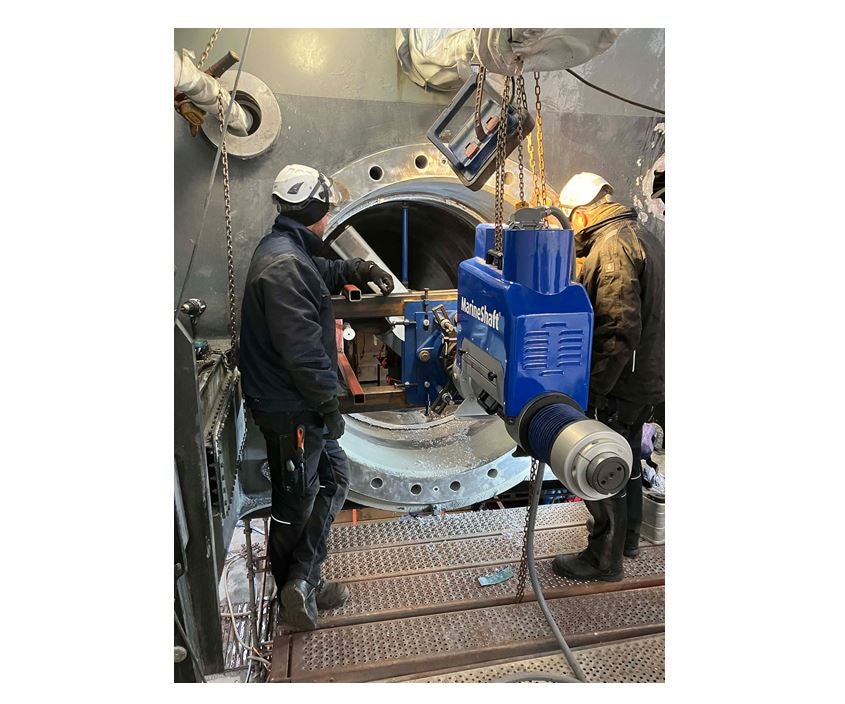

Our new machining capability was functional and necessary when we carried out this recent job which included the on-site machining of a seal seat for a waterjet with an outer diameter of 1,555mm.

This process involved :

- Boring the stern tube, boring the rudder neck bearings, and boring of the rudder horn

- Machining the cones in rudder blades, and machining the cones on shafts

- Welding rudder blade cones

- Machining and welding damage on the shafts

- Aligning the shaft line and rudder line

- Jack-up tests

- Run-out measurement services

- Shaft withdrawal

- Disassembly and assembly/fitting

- Modification

- Grinding and polishing

- Supervision

We hope you will keep us in mind for your next on-site request.