Cryonorm designs and supplies LNG marine fuel systems for both inland waterways as (short) sea-going vessels.

The company supplies tailor-made LNG solutions that meet the highest international standards and regulations, and are certified by appointed third-party inspection agencies for marine classifications.

Liquefied natural gas marine fuel systems

Cryonorm fully engineers complete LNG marine fuel systems, including bunker stations, Type C vacuum-insulated fuel tanks and connection spaces, as well as gas-processing, water-glycol, control, monitoring and emergency shutdown (ESD) systems.

The company installs, supervises and commissions LNG systems on-board ships, and provides assistance during the first gas trial, cool-down and fill of LNG. It also offers training, after-sale services and spare parts.

Cryonorm’s marine LNG fuel systems can be deployed on both inland waterway and seagoing, retrofit and new-build, dual-fuel propulsion or 100% full natural gas propulsion ships.

The company’s energy-efficient LNG systems reduce emissions, noise and ship fuel and operation costs, as well as provide cleaner engine rooms.

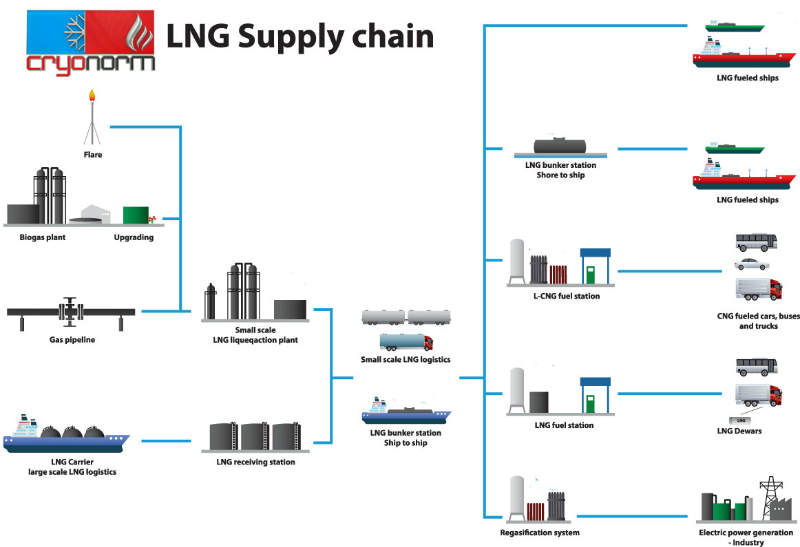

LNG bunkering systems

Cryonorm offers MID-approved shore-to-ship bunkering stations, including LNG storage tanks, pumps, flow meters and loading arms / flexible hoses.

The company is involved in several studies for small-scale LNG bunkering vessels that engage in ship-to-ship LNG transfer.

Cryogenic vaporizers for liquefied natural gas

Cryonorm supplies solutions for regasifying LNG, such as ambient air-heated and gas-fired designs.

About Cryonorm

Based near Amsterdam, the Netherlands, Cryonorm employs more than 100 people, including more than 18 expert cryogenic engineers.

Around 65 professionals manufacture systems at Cryonorm’s construction facilities, which cover an area of 8,000m².

Cryonorm has engineered, manufactured and installed Marine LNG fuel systems for:

- Argonon of Deen Shipping: the first dual fuel-powered inland ship was provided with one 40m³ LNG fuel system

- Eiger from Danser Containerline: Cryonorm retrofit the inland ship with a 60m³ system

- Greenstream and Greenrhine of Interstream Barging: the first two 100% gas electric-powered inland ships in the world, each provided with two 40m³ systems

- Coral Sticho and Coral Star of Anthony Veder: the dual-fuel propulsion ships were provided with two 100m³ systems

- Greenland and Ireland of joint venture JT cement, in which Erik Thun AB cooperates with KG Jebsen Cement (KGJ) from Norway. Dual-fuel propulsion ships were provided with a 140m³ vertical tank