ShaftMaster 1000 systems are propeller torsion meters, which display and record shaft horsepower, shaft torque, shaft RPM, total shaft revolutions, total shaft horsepower hours, and engine hours, triggered by an RPM set point.

High-speed and low-speed torsion meters for ships

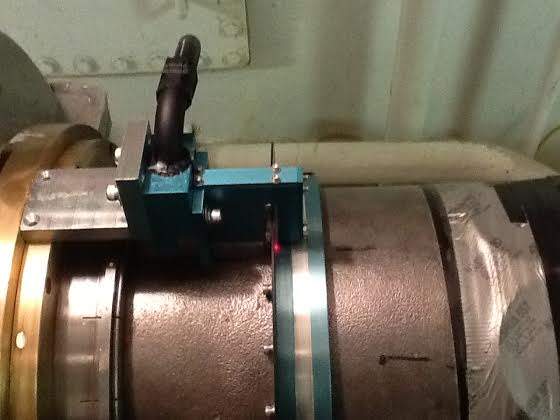

The ShaftMaster 1000F is our current system designed for high-speed and low-speed shafts using fiber-optic technology. Installations range up to 1,800 shaft RPM. The system comes prewired with a standard 20ft sensor cable. All that has to be done electrically is to run +24VDC, 120VAC, or 220VAC to the enclosure and to terminate the network to the touchscreen in the control room via four conductor-shielded wires. The source voltage is determined prior to installation. The torque rings are installed on the shaft and is bolted together with allen screws.

Environmentally-resiliant torsion meters

The ShaftMaster 1000M has been successfully installed for shafts up to 800RPM. The system is designed for very harsh environments where dirt and oil can be a factor. The 1000M has been installed on ships with oil leaks that have saturated our torque tapes but does not have an effect on the accuracy and longevity. The 1000M works with the same torque rings as the 1000F although the targets and the sensors are different. The 1000M can work without the torque rings by installing the torque tapes directly to the shaft. The 1000M can be used as a portable or a permanent system. The only limitation of the system is the shaft RPM. We can determine at what RPM we can go up to, based on your maximum RPM and the outside diameter of the shaft.

The ShaftMaster 1000F and 1000M use the same computer, program, and parameters which can be changed from the keypad. We recommend using the password protection which is available after entering the parameters, and the calibration number. An important option is that the data can be interfaced directly to your laptop or desktop PC and opened in Excel and can also be transmitted to the main office via email, or the data can be recorded to an SD microchip that can be removed from the system and copied via a USB port. Either system can replace your existing RPM system and give you more information such as an audible alarm when the shaft has stopped for a certain amount of time and indicates when the jacking gear has been engaged, and much more.

Stand-alone RPM system

The ShaftMaster 1000RPM system is a stand alone RPM system and can be upgraded to either the ShaftMaster Model 1000F or Model 1000M.

Pricing

ShaftMaster 1000F:

- Shaft diameter of up to 15in $10,000 plus shipping

- Shaft diameter of over 15in $12,000 plus shipping

ShaftMaster 1000M with torque rings:

- Shaft diameter of up to 15in $10,000 plus shipping

- Shaft diameter of over 15in $12,000 plus shipping

Without torque rings:

- All shaft diameters $8,000 plus shipping

ShaftMaster 1000 RPM:

- Portable unit $8,500 plus shipping

All prices are subject to change.

Hillhouse Industrial & Marine (HIM) believes in supplying all necessary installation items with the system. We understand the importance of having everything at your finger tips. Technical support is available at no charge but international support needs to be scheduled due to the time difference.