SecureLoad Systems, a joint venture by Admaren Tech and Hoppe Marine, has won the Innovation Award in the Loading & Stability category in the 2025 Ship Technology Excellence Awards for its SecureLoad platform. SecureLoad is a web-based loading computer and stowage planner that addresses long-standing limitations of traditional, desktop-era vessel loading systems.

Its innovative approach of unifying onboard and shoreside planning in a single calculation engine, integrating mesh-based 3D cargo, and introducing advanced ballast distribution and trim optimization has been key to its recognition in this category.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

The SecureLoad platform is designed to shorten planning cycles, reduce avoidable errors, and bring stability, securing, and regulatory checks into the planning phase rather than leaving them as late-stage validations.

This focus on cargo operations as a digital laggard within shipping is central to the company’s vision. As CEO Nikhil Mathew notes, while digital adoption has accelerated in commercial, technical, crew, and shipbuilding domains, cargo operations – the very core of shipping – have remained largely traditional. Planning is still fragmented across spreadsheets and standalone software, often lacking accuracy and consistency between ship and shore. SecureLoad is presented as a response to that gap: a web-based framework that combines 3D visualization, optimization algorithms, and real-time validation of strength, stability, and compliance in one environment.

“This recognition is a proud milestone for the entire team. It reaffirms our belief that the next era of maritime digitization lies in smarter, safer, and fully connected cargo operations and we’re proud that SecureLoad is leading that change.”

– Nikhil Mathew, CEO, SecureLoad Systems

Unified ship–shore loading and stability platform

A defining aspect of SecureLoad’s design is that the same planning and calculation engine runs in both the vessel and the office. SecureLoad Onboard operates entirely inside the ship’s local network, giving crew and project teams access to the loading computer from any onboard device while satisfying maritime regulatory and connectivity constraints. SecureLoad Cloud provides the shoreside workspace where engineers, charterers, and port captains plan on the same approved ship model and synchronize changes back to the vessel when connectivity is available.

This single-engine approach is intended to replace fragmented, file-based workflows in which multiple versions of loading conditions circulate between vessel, owner, consultants, and charterers. CTO Binoy Pilakkat frames the starting point for the product in these terms: stability, strength, and cargo decisions “are still made in disconnected spreadsheets, standalone PCs, and email attachments. When something changes – a cargo unit, a draft restriction – entire plans often need to be rebuilt, and nobody is completely sure which version is the truth.” From the outset, the goal was to “build a single calculation and planning engine that runs both onboard and, in the cloud, so crews, engineers, charterers, and port captains all work on the same approved ship model, in real time, from any browser.”

By keeping one source of truth for the ship model and loading logic, the platform aims to reduce version drift and misalignment between what is planned ashore and what is executed on board. Browser-native access and a fleet workspace with role-based permissions allow owners to control the approved model while enabling collaboration with external partners at scale. Every change and scenario is recorded, creating an audit-ready activity trail across vessels and users. This shift from file-based handoffs to what Pilakkat describes as “a continuous loop from planning to execution” is central to SecureLoad Systems’ positioning in the Innovation – Loading & Stability category.

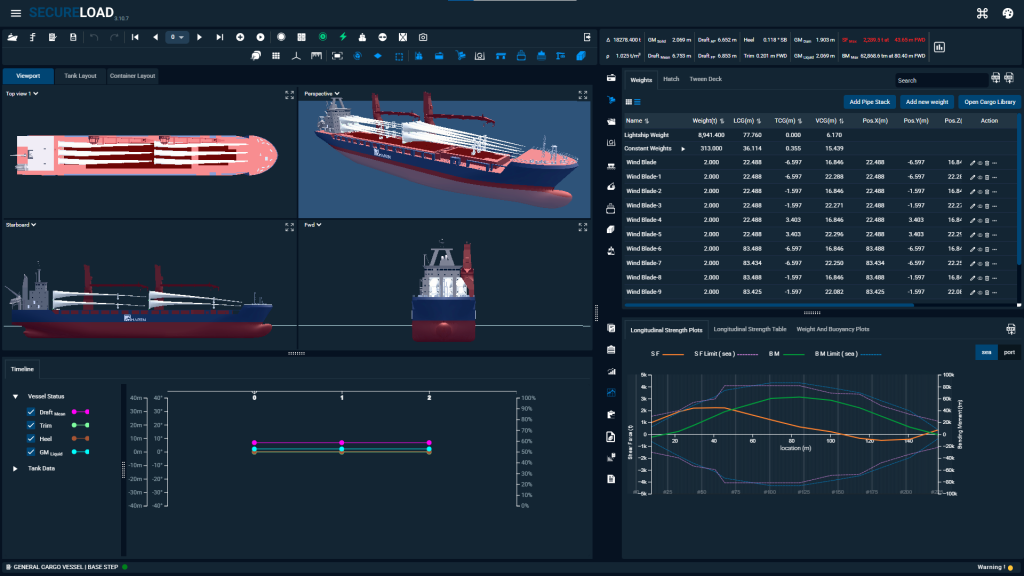

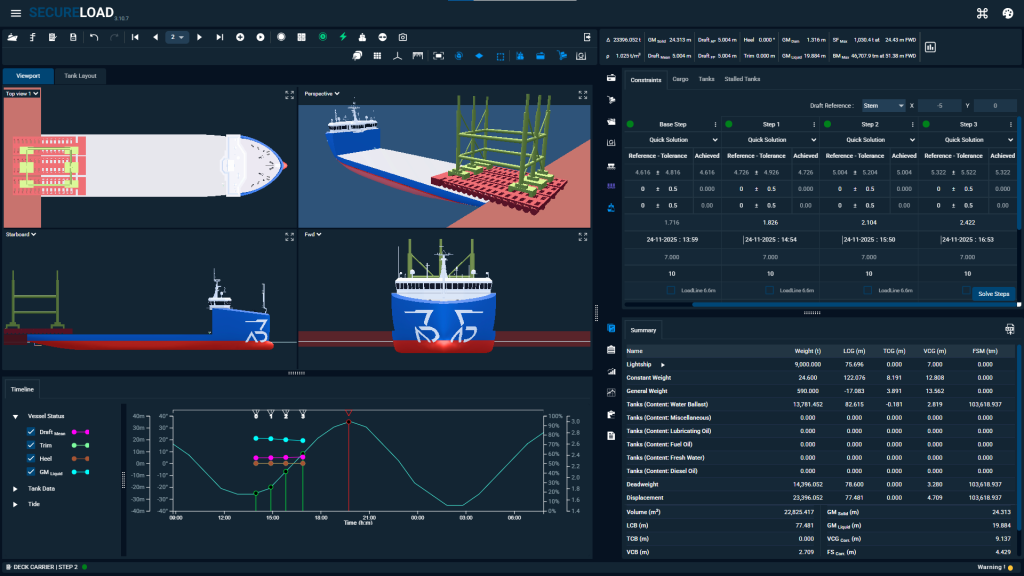

SecureLoad has been deployed on a range of complex vessels and operations. On Rotra Futura and Rotra Horizon, the latest-generation MPP heavy-lift vessels, it is used to simulate cargo loading scenarios for wind industry components, including blades, towers, and nacelles. Users work within an interactive 3D environment linked to the underlying calculations, allowing stability, strength, and compliance to be verified in the planning phase. On OBANA, described as the world’s largest jack-up vessel, SecureLoad supports preparation of complex loading cases for offshore decommissioning projects, including lift and ballast simulations. These applications show the unified ship–shore architecture in use in high-stakes heavy-lift and offshore work, where operational and regulatory requirements are demanding.

From snapshot files to computed, visual workflows

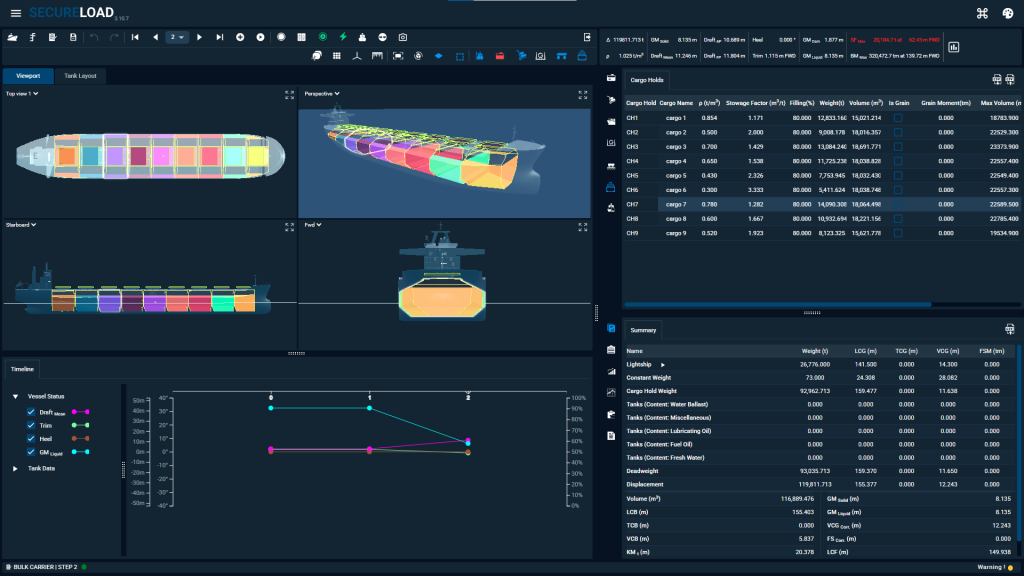

SecureLoad changes how loading and stability work is structured by moving away from isolated, static loading conditions toward a step-based operational workflow. Instead of creating and juggling separate files for different stages of an operation, users can model sequences such as load-in, lift-on, float-in/float-off, ballast transfers, and crane operations within a single worksheet. At each defined step, the system recalculates stability, longitudinal strength, and other criteria, preserving context across the full operation.

This approach is particularly relevant for heavy-lift, semi-submersible, and project cargo operations, where risk often lies in the transitions between states rather than in a single final condition. By keeping the operational sequence in one continuous plan, SecureLoad reduces the need for manual resets and multiple documents and supports cleaner internal and external approvals for complex jobs.

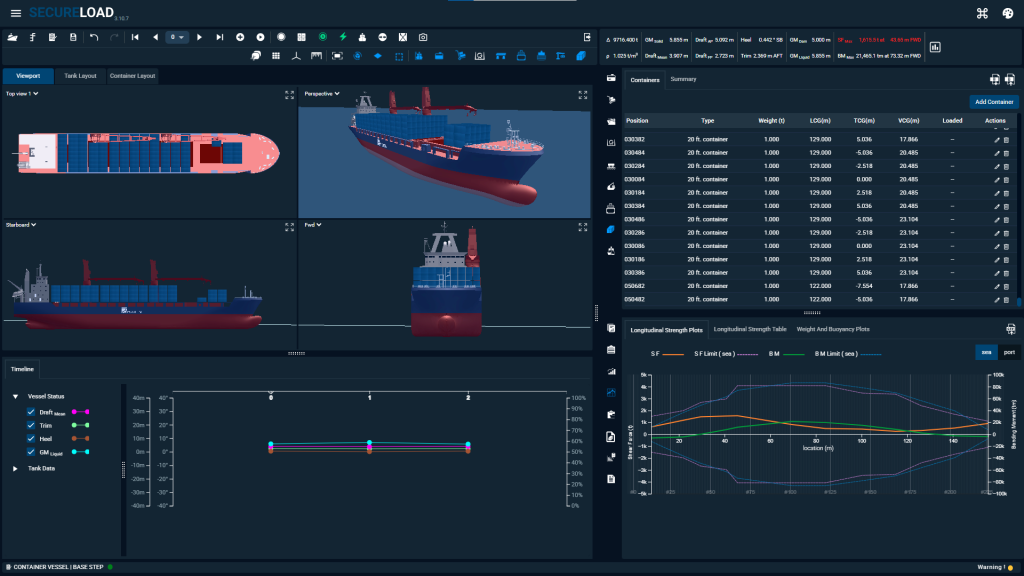

The platform’s interactive 3D environment reinforces this operational view. SecureLoad uses mesh-based cargo models that capture exact geometry, centroid positions, and clearances, and links them directly to traditional table inputs. Instead of relying on simplified two-dimensional representations, operators can plan with three-dimensional cargo geometries, including collision awareness. This visual accuracy is important in sectors such as offshore wind, where large, irregular components must be positioned precisely on deck or in holds with tight spatial margins. The combination of table-based data and 3D visualization is intended to improve communication between office planners and deck personnel and to reduce rework at the quay.

On the ballast side, SecureLoad includes an optimization solver that recommends tank fillings under real operational constraints, with the option to interface with ballast control systems provided by Hoppe Marine. Users can define desired conditions and constraints, and the solver computes ballast distributions that meet those requirements while respecting the vessel’s reality. According to the submission, this can reduce expert time spent on routine ballast calculations from as much as a week of manual work to less than an hour in typical cases. Pilakkat highlights these elements as central to the product vision, citing “step-based workflows, advanced ballast optimisation, and interactive 3D planning” as integral to the shift away from file-driven processes.

Beyond specialist users, SecureLoad Systems positions the platform as a system that aligns multiple functions around a single interface. In the words of CEO Nikhil Mathew, “What once required multiple software tools and the experience of seasoned planners or captains can now be achieved within a single interface, aligning chartering, operations, engineering, and onboard teams seamlessly.” In this framing, the loading computer or “loadicator” is recast “from a vessel-only tool into a comprehensive cargo operation support system that ensures planning and execution work hand in hand.”

Connecting planning, execution, and governance across fleets

Beyond its technical features, SecureLoad is structured to close the gap between planning and field execution at fleet scale. Role-based access control allows owners to keep the ship model under their governance while giving charterers, naval architects, and heavy transport engineers defined access to create, review, and adjust load cases. Multiple users can collaborate on the same worksheet, with instant recalculation and shared context in the browser, which reduces reliance on serial handoffs and email chains.

The platform also provides tools to carry digital plans through to deck-side implementation. A built-in DXF exporter generates stowage drawings directly from loading conditions, using configurable layers and conventions suitable for CAD systems and work packs. This reduces the need to redraw plans in external tools and lowers the risk of discrepancies between the approved digital plan and the drawings used on board and on the quay.

SecureLoad is designed to align planning data with the vessel’s real-time status where possible. Integration with onboard tank sensor systems via Modbus and similar protocols allows live tank readings to be reflected in the loading model. Optional ballast control integration with Hoppe Marine systems allows ballast transfers defined in the plan to be executed via remote valve control, connecting the computed ballast solution to controlled execution. These capabilities are intended to reduce deviations between planned and actual conditions and to support safer ballast workflows.

The breadth of modules available within SecureLoad supports a wide range of vessel types and operations in a single platform. General modules cover intact stability, longitudinal strength, ballast distribution, trim optimization, and damage stability. Vessel-specific modules address general cargo configuration, grain and bulk with grain code checks, container operations with lashing assessments via DNV StowLash, crane operations for single and tandem lifts, load-in/load-out under changing tide and pump capacity conditions, float-in/float-off for docks and semi-submersibles, and tanker cargo volume calculations with temperature corrections. Bringing these domain-specific functions into one system is intended to reduce tool switching and data transfers and to support consistent checks across different operation types.

From an operational perspective, SecureLoad is built to work within typical maritime connectivity constraints while still benefiting from modern software delivery. The onboard version is fully offline-capable and runs on the vessel’s internal network, while the cloud-based office version delivers centralized updates of new features and security improvements. This combination helps keep fleets on a common, current version of the software without frequent onboard installation cycles, while allowing vessels to continue working even when connectivity is limited and to synchronize with shore when links are available.

For SecureLoad Systems and its partners, the Innovation Award is described internally as a validation of the direction taken so far rather than an endpoint. As Pilakkat states, “This award recognizes that shift. We see this as just the beginning, and this Innovation award gives our team even more energy to keep pushing the standard of what a modern loading computer should be.”

“We are incredibly proud that SecureLoad has been recognized with the Ship Technology Excellence Award in the Innovation category. For us, this is more than a trophy – it confirms that the industry is ready to move beyond desktop-era loading tools and embrace a new way of working between vessel and shore.”

– Binoy Pilakkat, CTO, SecureLoad Systems

Company Profile

SecureLoad Systems Pvt. Ltd. is a new-generation maritime technology company built to modernize how vessels are planned, loaded, and operated. Driven by naval architects with deep expertise in hydrostatics, hydrodynamics, 3D Ship CAD, and optimization algorithms, the company objective is to solve long-standing industry challenges: outdated legacy tools, broken ship–shore workflows, and the lack of intelligence during cargo planning combined with real-time visibility into vessel loading conditions.

SecureLoad is the result of a strategic collaboration between Admaren Tech in India and Hoppe Marine in Germany. Together, both organizations have created a unified platform that brings modern web technology, interactive 3D, High fidelity ship calculations, and fleet-wide connectivity into a single ecosystem with special focus to bulk, breakbulk, heavy-lift, offshore vessels, and complex units such as floating docks.

Its product suite includes:

• Loading Computer – The world’s first web-based loading computer with automated ballast features, role-based access, interactive 3D, mesh-based cargo definition and class-approved accuracy.

• Fleet Cargo Planner – The only cloud platform that provides real-time fleet visibility, stability and strength checks, collaboration across chartering and operations, and auto-sync with onboard systems.

• Stowage Planner 3D – An upcoming cloud-native 3D stowage planner that converts unstructured enquiries into detailed, CAD-grade stowage plans. (Under development)

• Acceleration & Lashing – A next-step 3D environment for designing and validating lashing arrangements using advanced force solvers built on IMO CSS and CTU Code standards. (Following Stowage Planner 3D)

• Structural Digital Twin – A cloud-based FEA twin that connects live ship data from Hoppe’s onboard systems to visualize actual structural loading in real time. (Following Acceleration & Lashing)

SecureLoad is built on five core strengths: advanced naval architecture, modern web technology, high-end 3D visualization, optimization algorithms, and deep understanding of commercial shipping workflows. This foundation enables the platform to automate repetitive tasks, support complex decision-making, empower commercial teams with better intelligence, and give both ship and shore teams a consistent, real-time understanding of every load case.

Today, SecureLoad supports operations on next-generation heavy-lift vessels, MPP carriers, some of the world’s largest jack-ups, and floating docks. Approvals from multiple IACS-class societies, including DNV, RINA, KR, and IRClass, validate the accuracy and reliability of its computation engines. Active deployments across Europe and Asia further demonstrate the maturity and robustness of the platform.

Headquartered in Kochi and supported by Hoppe Marine’s global footprint, SecureLoad Systems serves fleets worldwide, connecting chartering, operations, engineering, and onboard teams in a single, continuously updated environment. The result is faster planning cycles, safer operations, higher utilization, and a fundamentally smarter way to manage every voyage across an entire fleet.

For more information, visit www.secureload.com

Contact Details

Vivek Nair, Head – Marketing

Links

Website: https://secureload.com/