The 6,600dwt multipurpose vessel, Andromeda, was built by Dutch shipbuilder Bodewes’ Scheepswerven for shipowner B&N Moerman, also based in the Netherlands.

Andromeda’s sister vessel, built in Bodewes’ Hoogezand yard, was due to enter service in April 2000. Both vessels were destined to be deployed between Europe, the USA and Canada, transporting parcel cargo.

B&N Moerman is a subsidiary of the Swedish shipping company B&N Nordsjofrakt. Both vessels have been assigned to the group’s Gothenburg bulk chartering broker B&N Partship.

Andromeda flies the Netherlands flag and has Bureau Veritas classification.

DESIGN

Andromeda has two flush-sided holds, the first reflects the foreship fairing, while the second hold is fully box-shaped. The cargo section accounts for some 72% of the frame length of the hull overall. The hatchway widths correspond directly to the hold breadth, which is conducive to optimisation of the hull envelope for freight revenue purposes. The hold type is also well-suited to B&N’s target markets and strengths of forestry, steel and aluminium.

The two holds provide a total cargo capacity equivalent to 332,600ft³. Moduling of the below-deck areas enables the accommodation of containers. Andromeda has a total rating of 416 TEU, deriving from the availability of 174 TEU slots in the holds, including three tiers of 9ft 6in boxes and 242 TEU on deck. Stanchions on the outer part of the bulwarks enable a six wide stow to be accommodated above decks. The hatches have been strengthened to take the container stack loads, which are absorbed into the ship’s structure. The vessel has a substantial wavebreak to protect cargo stowed on the weatherdeck.

Consideration was also given in the design to the handling of hazardous and sensitive cargoes. The enhancement of freight catchment potential by fitting the first hold for 30 changes of air per hour means that certain types of fresh produce can be transported and delivered in the required condition.

The versatility of Andromeda is also increased by two portable, separation bulkheads in each hold. The separation bulkheads can be set up in seven positions. In addition, the moveable bulkhead pontoons can be deployed to create a partial tweendeck in either hold. The pontoon covers are positioned using the deck gantry fitted for handling the weatherdeck hatch panels.

Accommodation is provided in single berth cabins for up to nine crew members, though a crew complement of eight is likely to be the norm for Andromeda. Labour saving devices include the adoption of double winches, fore and aft.

In building Andromeda, Bodewes adopted a modular structure and a high degree of pre-outfitting. A vessel like Andromeda, therefore, consists of about 46 sections, assembled into five main ring sections. The yard itself produces the more complex man-hour intensive sections, while more standard parts are subcontracted.

PROPULSION

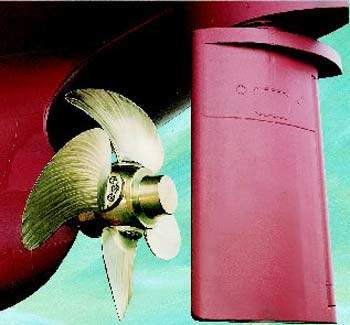

Andromeda is powered by a MaK M32 series medium-speed engine, delivering an output of 3,840kW. Power is transmitted from the engine through Rent Tacke reduction gearing to a Berg controllable pitch propeller. The installation offers an open-water speed of 14 to 15 knots, with 14 knots being the advertised service speed.

Electrical power for the vessel is provided by two 253kW gensets, advantaging operating economics from the use of a 348kW shaft alternator driven off the gearbox during the sea passage.

Ship manoeuvrability is assisted by the installation of a 300kW Berg bow thruster, along with the flap-type rudder and main, variable pitch propeller.