The Lynx operated on the Wellington-Picton crossing for the New Zealand operator, Tram Rail. It was aimed principally at the fast ferry/freight market. The vessel is certified by DNV to 1A1 HSLC R1 Car Ferry ‘B’ EO standard.

Tram Rail axed the service in April 2005 because of new environmental regulations imposed by the government. The service was replaced by a new ferry called Kaitaki, which met the environmental regulations.

The Lynx was subsequently purchased by Port Authority of Trinidad and Tobago, which changed the ferry’s name to T&T Express. The ferry service runs between Port of Spain and Scarborough.

Ferry design

The Lynx has an overall length of 97.22m, making it the largest aluminium-hulled vessel built in Australia. It is the first of the Evolution 10B series, 2m longer than the Evolution 10 with a waterline length of 92m. It has an overall beam of 26.2m, a moulded depth of 7.8m and a hull draught of 3.4m. Its deadweight is 750t.

The Lynx features the new retractable T-Foil located at the aft end of the centre bow to increase speed. Together with the increased hull length, midship design and clearances, this is said to reduce incidences of motion sickness by up to 40% in higher sea states. Developed jointly by Incat and Maritime Dynamics, the new foil retracts out of the water and behind the centre bow when not in use.

The Lynx is fitted with six evacuation stations; two on each side of the vessel contain an IMO-approved MES (Marine Evacuation System) with an additional liferaft access station on each aft mooring deck. An MES consists of an inflatable slide, which connects with multiple 100-person liferafts.

Facilities

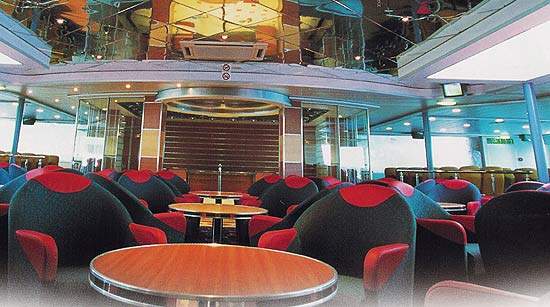

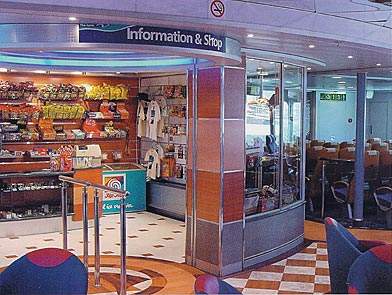

The uni-deck design can accommodate up to 900 people. There is a central midships lounge featuring the centreline bar with casual stool seating, all situated on the lower passenger floor level. The outboard raised seating areas in the forward lounge incorporate recliner style seating. Aft and outboard of the central lower wheelhouse/crew accommodation and passenger toilet block are two casual lounges with tub-style seats.

Air conditioning is provided by Sanyo reverse cycle head pump units throughout, capable of maintaining between 20-22°C and 50 per cent RH with a full passenger load, and an ambient temperature of 32°C and 50% RH

The vehicle deck consists of 380m of truck lanes and 360m by 23m of car lanes. This equates to a total of 1,200m of car lanes – 267 cars, or 180 cars and 12 road freight trailers.

The raised control station (wheelhouse) on-board Incat Tasmania is small for a vessel its size. Its large windows provide 360° visibility for the officers over the new aerodynamic superstructure, while an aft-facing docking console and CCTV monitors negate the need for bridge wings with their associated windage. The control station is fitted with the latest in electronic, navigation and communication equipment to comply with High Speed Craft Code Sea Area A2.

The ‘rapid access’ (deckhead) and ‘lightweight’ (bulkhead) fire protection systems meet demands for lighter weight and faster installation/removal for this type of craft. An addressable fire detection system, CCTV cameras, zoned fire sprinkler systems and hydrants protect engine-rooms, vehicle decks and passenger areas. It is also fitted with portable fire extinguishers, fire-protection suits and equipment, water fog applicators, breathing apparatus, international connections and fire control plans to meet IMO requirements.

Propulsion

The Lynx is powered by four Ruston 20RK270 medium-speed diesels, developing in excess of 28,000kW. The engines drive transom-mounted steerable Lips 120E waterjets via Reintjes VLJ6831 gearboxes. All four waterjets are configured for steering and reversing. A new feature is the introduction of the new Lips 6-blade, high-speed, high-pressure waterjet, incorporating a control arrangement. The new hydraulic cylinder layout eliminates many of the maintenance and operational problems experienced on previous waterjet models. An additional benefit of the new waterjet is the significant reduction in weight compared with the earlier 150D units, providing a saving of around 30t.

The main engine dry-exhaust system propels engine exhaust away from the vessel via twin funnels on top of the aft superstructure, instead of into the tunnel between the vessel’s hulls.