Extending the service life of engines

The enzymes contained in XBEE have the exceptional function of naturally cleaning fuel systems, including storage tanks, settling tanks, centrifuges, daily tanks, and engines.

XBEE is a natural fuel treatment safe for use in all engines and fuels. Based on natural enzymes, XBEE has been commercialised worldwide for more than twenty years, improving shipping operation costs. Enzymes eliminate contaminants, clean tanks and filters, remove carbon deposits, and reduce fuel consumption and gas emissions.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

XBEE Enzyme Fuel Technology is designed to clean up vessel fuel systems, dispersing all kind of organic contaminants, as well as water, and sludge.

Our natural fuel treatment reduces toxic gas emissions, fuel consumption, and maintenance costs. Enzymes can purify all marine systems, such as fuel tanks, filtering equipment, and engines.

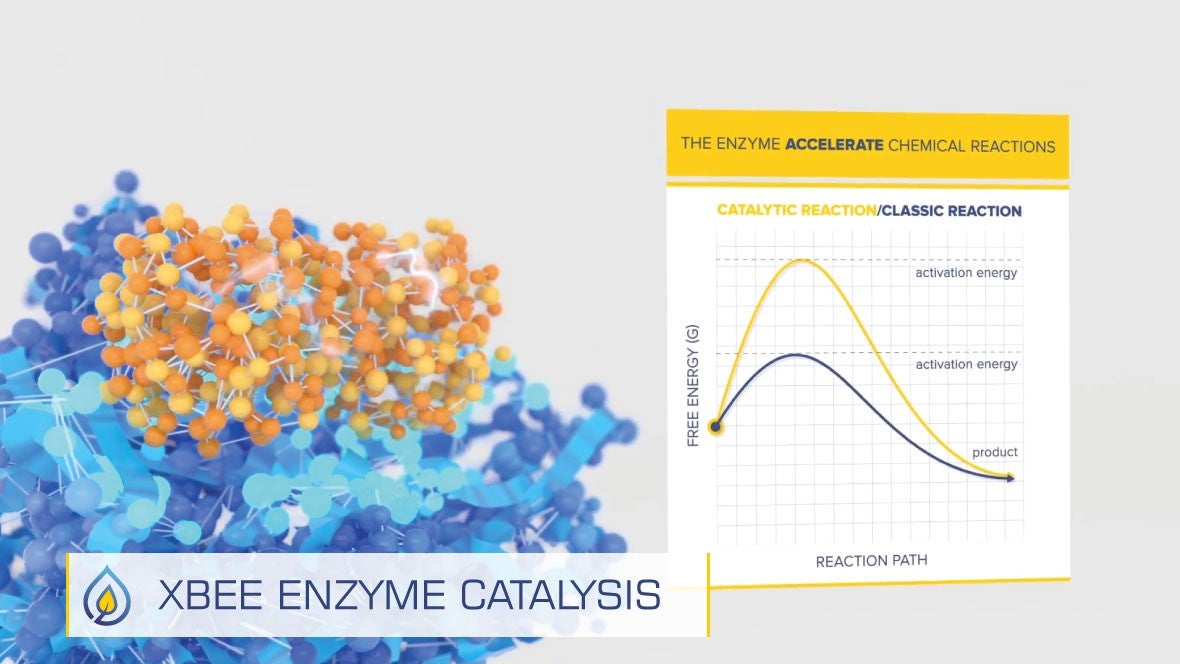

The organic composition of XBEE ensures it complies with all international fuel standards for gasoil, MDO, and heavy fuel oils. XBEE enzymes improve the molecular structure hydrocarbon molecules in fuel and increase the efficiency of the combustion process to prevent residue and carbon particles from being formed.

Enzymes are powerful dispersants and surfactants that take away the contaminant’s ability to stick to fuel tank walls.

XBEE removes natural contaminants found in fuel, helping to clean tanks and filters. It also minimises the workload for separators.

It is added during bunkering to ensure the optimal volume of the fuel technology is well dispersed throughout the fuel. XBEE is recommended for diesel, biodiesel and HVO, heavy fuel oils, and mazout.

XBEE is a non-chemical agent that is compatible with all fuels and ship engines. The cleaning agent removes all contaminants from fuel, in addition to carbon deposits or soot in various parts of the engine.

The filtered fuel and elimination of contaminants naturally clean all engine components, such as pipes, valves, pistons, filters, and injectors.

XBEE restores the initial fuel consumption rate of engines through the removal of contaminants and other deposits in pipes and tanks. It also helps in preventing damage and wear to pumps and injectors.

Purified fuels burn faster and more efficiently in vessel engines, providing more power and reducing consumption.

Laboratories have measured specific fuel consumption reduction of -6.5% in diesel engines and -4,7% in HFO.

Vessels using XBEE can perform more efficiently, which means they will produce fewer greenhouse gas emissions, including carbon dioxide, nitrogen oxide, and other particles.

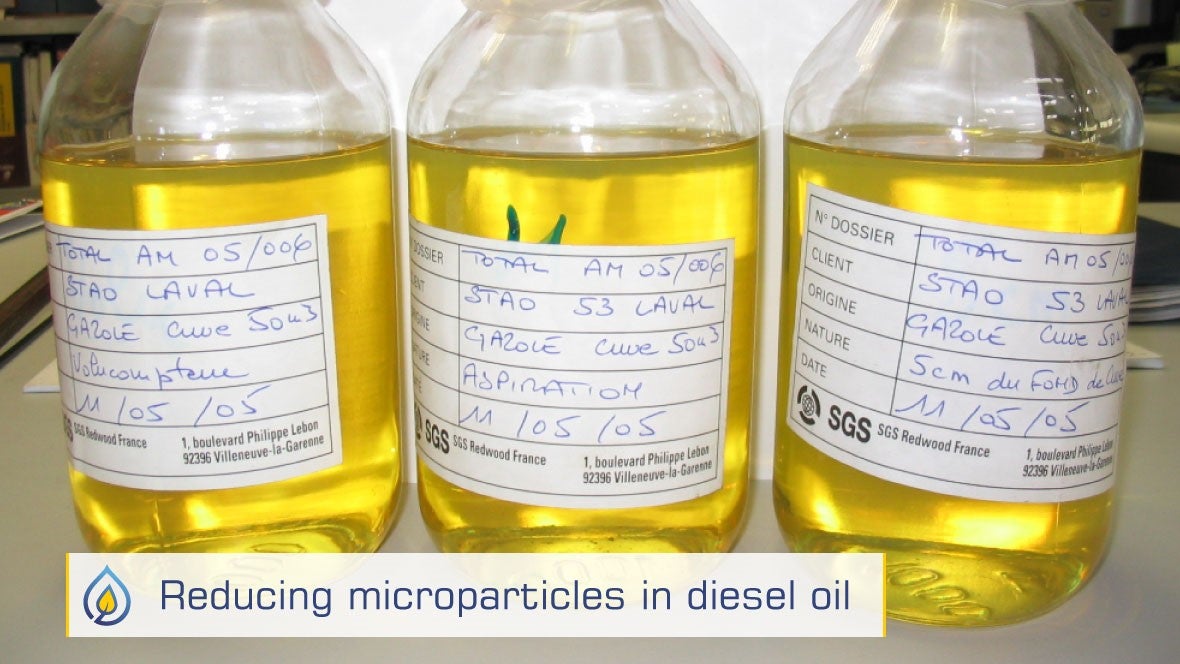

Said improvements have been repeatedly measured by laboratories, such as Bureau Veritas, Dekra, Eurofins, and SGS. All gas emissions, such as carbon dioxide (CO2), nitrogen oxides (NOx), and particulates, are significantly reduced thanks to the action of the enzymes in the fuel.

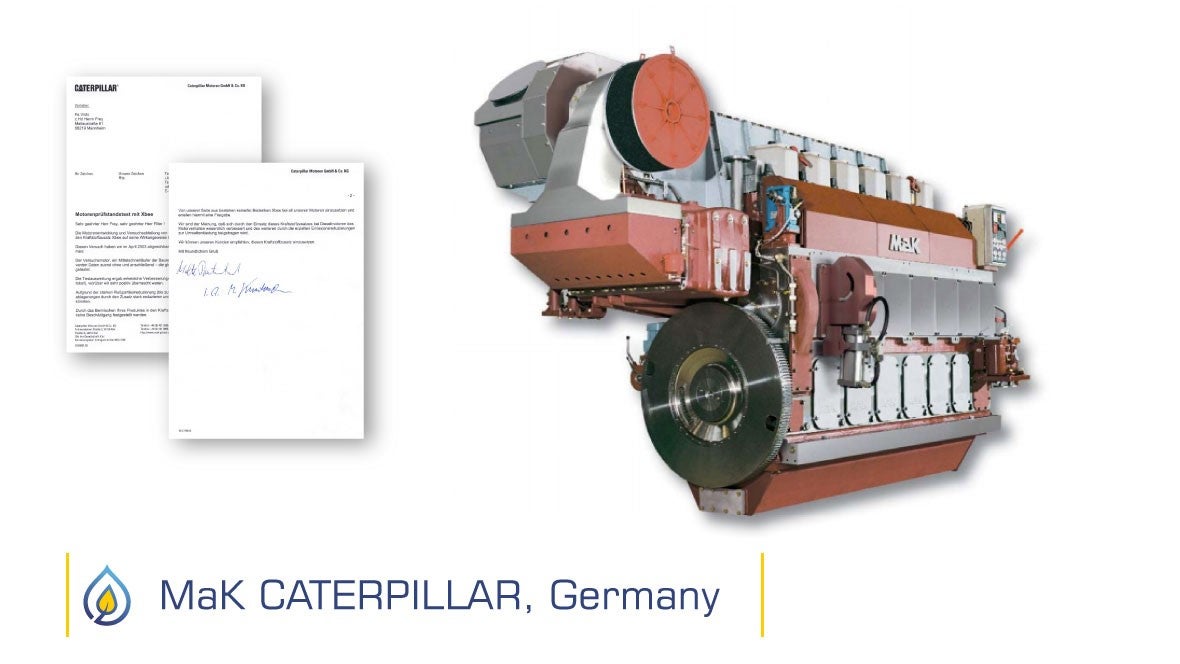

Det Norske Veritas (DNV) has carried out analysis that shows XBEE is safe for maritime vessel engines and their components. Major original equipment manufacturers (OEMs) recognise or recommend the use of XBEE in their engines.

Fuels that have been treated with our technology comply with all standards, including EN590 for diesel and gas oil, and ISO 8217 for DMA and heavy fuel oil 180 and 380.

The enzymes contained in XBEE have the exceptional function of naturally cleaning fuel systems, including storage tanks, settling tanks, centrifuges, daily tanks, and engines.

MARPOL regulations have forced virtually the entire global marine industry to have to make a tough choice: stick with HFO and install expensive sulphur scrubbers, or switch to more costly low sulphur distillate blends.

Several tests have shown that the enzymes in XBEE target aromatics.

The drilling, producing, shipping, and refining of one litre of diesel fuel produces 0.60kg of carbon dioxide.

VPS is considered one of the world’s leading fuel testing companies, testing to ISO 8217, with full ISO 17025 accreditation.

It is generally accepted that test methods for diesel also effect the test itself.

Intertek Hamilton in Ontario, Canada, tested XBEE Enzyme Fuel Technology to measure the impact of its unique enzyme formula on reducing the harmful small particles in aged diesel fuel.

Exhaust gas cleaning systems, or 'scrubbers', are highly effective in reducing sulphur dioxides and particulate matter produced during combustion.

The SNSPOOL is a collaborative agreement between nine oil and gas operators who primarily operate on the Dutch Continental Shelf, with some minor activities in the UK, Denmark, and Germany.

Fuel is treated with XBEE Enzyme Fuel Technology, a partner company of Green Marine Europe.

Green Marine is an environmental certification program for the North American marine industry. It is a voluntary, transparent, and inclusive initiative that addresses key environmental issues through its 14 performance indicators.

Measurements have been carried out by Ascal. This laboratory, now known under the name Kali’Air, was approved then by decree of the French Ministry of Ecology, Sustainable Development and Energy, and also accredited by Cofrac (French Accreditation Committee).

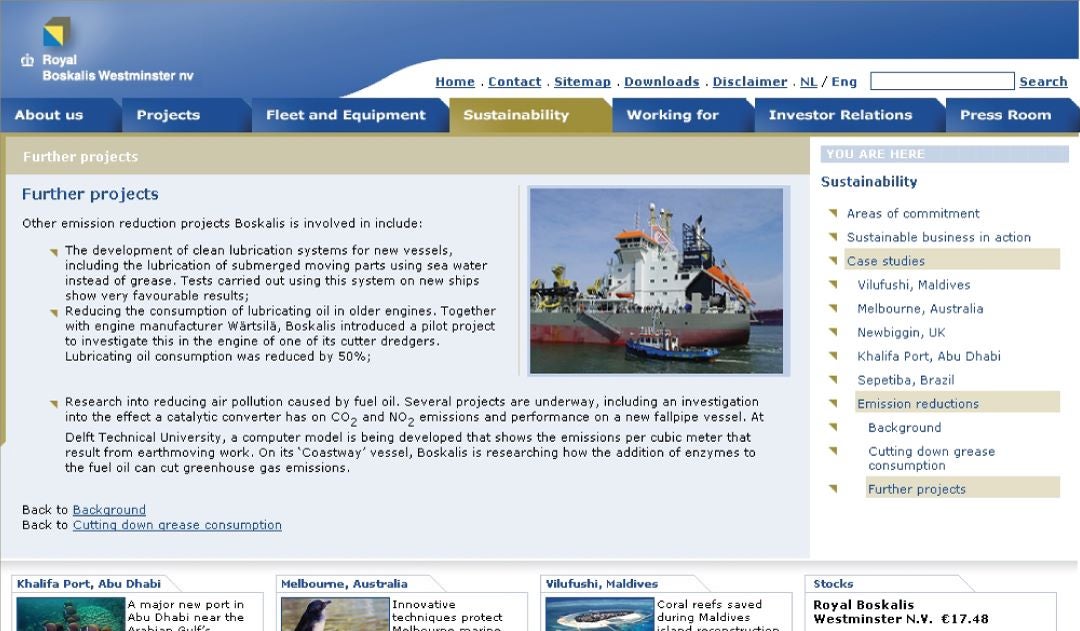

The results, analysed by Boskalis personnel, demonstrate how significant the impact of XBEE Enzyme Fuel Technology is on gas emissions and specific fuel consumption in ships working regularly on low loads, such as dredgers, tugs, and cable layers.

The shipping company Naviera de Galicia S.A. operates three cargo vessels: the M/V Mandeo and the sisterships M/V Finita R and M/V Manuela E, all powered on intermediate fuel oil 180.

In February 2018, the Dutch fuel supplier FinCo Fuel introduces a new fuel called ChangeXL powered by XBEE. The company offers fuels treated with XBEE Enzyme Fuel Technology in Benelux, and its affiliate Gulf Bunkering BV distributes Gulf Marine ChangeXL in several ports in the Netherlands.

MaK Caterpillar Senior Test Engineer and Head of Engine Development and Testing Malte Rautenstrauch has tested XBEE Enzyme Fuel Technology.

Prior to treatment with XBEE Enzyme Fuel Technology, a control trial was performed to collect data from a 1440kW DMA BTS auxiliary motor, known as the GE1.

Our 20-L cans can treat up to 80,000 litres of fuel and are designed for small units, such as tugboats, dredgers, trawlers, and gensets.

Our 208-L drums can treat up to 832,000 litres of fuel. They are mostly used onboard large vessels, such as cruise ships, ferries, container ships, and tankers.

Our 1,040-L IBCs can treat up to 4,160 m³ of fuel, and can be used by marine fuel distributors, and large offshore vessels and platforms.