Pronova Systems

Marine Fuel Optimisation System for Ships

Pronova specialises in electrical and automation systems for the marine industry to optimise vessel performance, save fuel and lower emissions.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Pronova specialises in electrical and automation systems for the marine industry to optimise vessel performance while reducing fuel consumption and emissions.

Our Ship Performance Optimizing System has been tested and installed on a variety of vessels, including tug-barge systems, ferry boats, cruise liners, container ships and bulk carriers. It offers fuel savings of more than 10% from ship speed optimisation alone. Other optimisation functions can further enhance cost-efficiency.

Vessel fuel and performance optimisation system

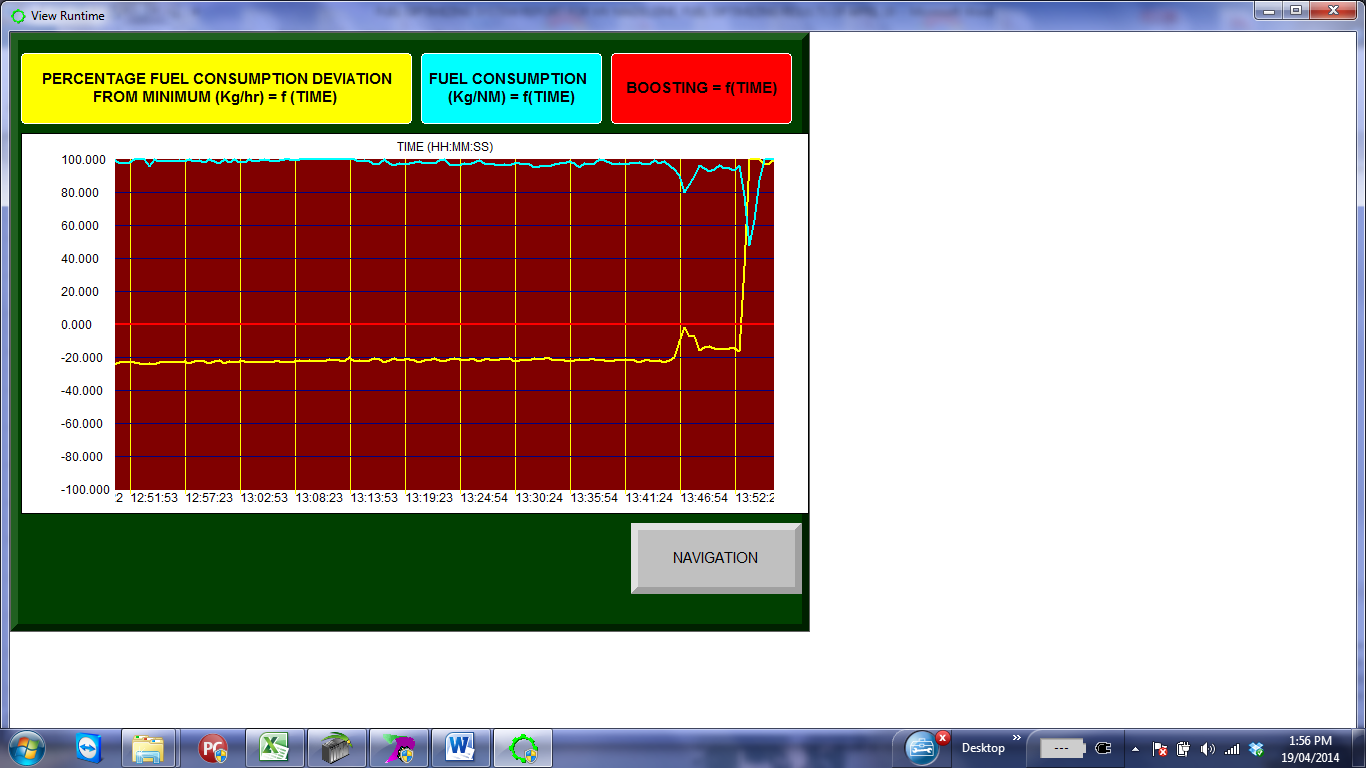

With a fuel saving of at least 10%, the optimisation system features continuous calculation of the optimal speed to enhance performance in any marine environment. It minimises the possibility of human error as a cause for fuel overconsumption.

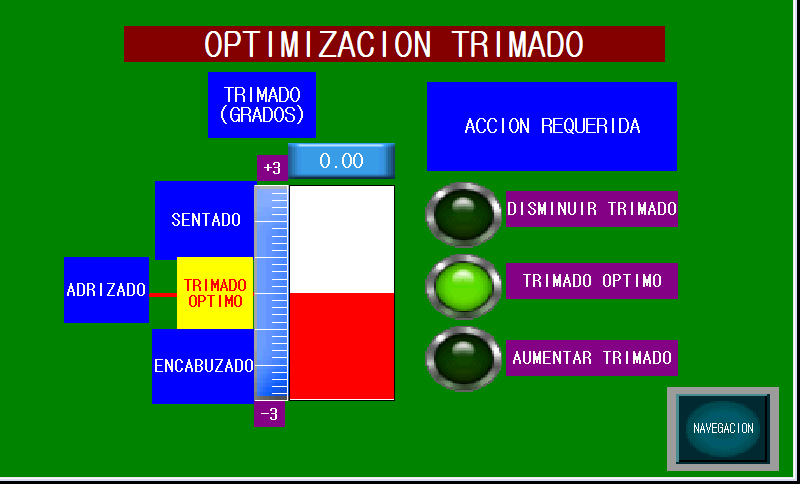

The system can help the crew to establish the optimal trim corresponding to the minimum fuel consumption at any moment of the operation. It offers tank gauging system monitoring, in addition to accurate fuel bunkering and analysis for fuel loss trends. Automatic daily reports can be customised according to client requirements.

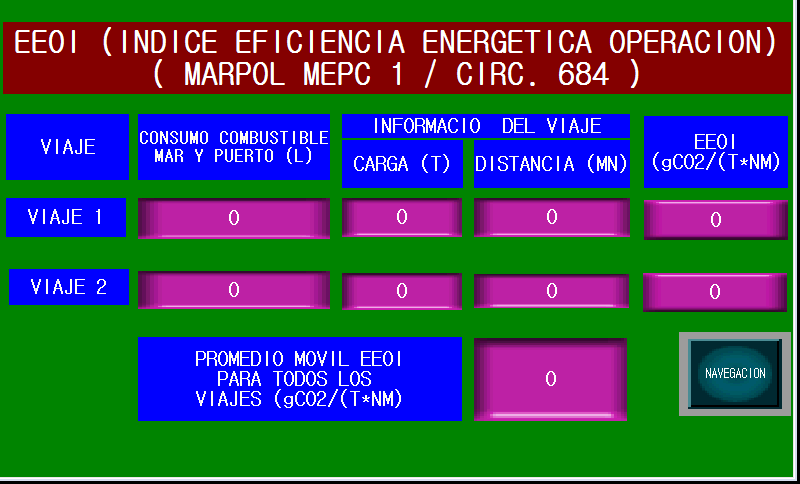

In addition to fuel savings, the Ship Performance Optimizing System reduces nitrogen oxide (NOx), sulphur oxide (SOx) and carbon dioxide (CO₂) emissions according to maritime pollution (MARPOL) Annex VI and the energy efficiency operational indicator (EEOI).

Ship fuel use optimisation for cost savings

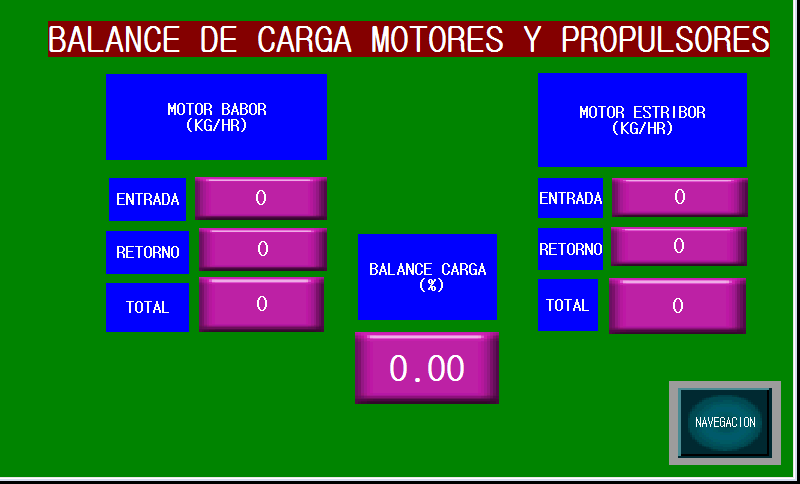

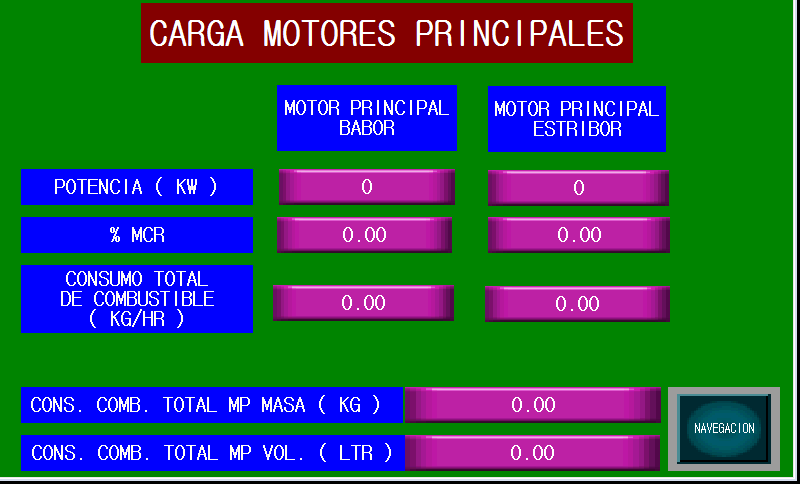

Our system offers load balancing between the ship’s main engines or propellers, as well as measures the engine’s kilowatt load to avoid the usage of power and torque meters.

The system can be easily installed on ships currently in operation or under construction without disturbing the functionality of other systems. The initial cost of the installation can be recovered from fuel savings within six months.

There are no additional costs after the installation, and there is no periodic tuning or regular maintenance required. Support for troubleshooting or supervision is available through the internet.

Fuel optimisation for pilot transfer vessels

The Ian Taylor Company is a leading ship owner and agent specialised in operating pilot transfer vessels in South America. The Kaitek vessel is well-known by pilots transferring to and from ships in Chile, in the Magellan Strait entrance to the Atlantic Ocean, with adverse navigational conditions.

As part of efforts to demonstrate its commitment operational safety and environmental protection, the company initiated a series of projects to upgrade its fleet to be permanently in line with International Maritime Organization (IMO) requirements, including the upgrade of Kaitek.

Pronova’s Ship Performance Optimizing System was chosen to be installed on board the Kaitek. Fuel cost is the most important expense for the vessel’s operation. In order to increase the ship’s efficiency, fuel consumption and exhaust gas emissions have to be reduced.

The optimising system installed on the Kaitek is able to provide the crew with the necessary real-time information to minimise fuel consumption and air pollution, as well as optimise ship efficiency and profitability.

Additionally, the system is designed to meet all requirements under the Ship Energy Efficiency Management Plan (SEEMP) and MARPOL Annex VI. By using a series of instruments, high-tech components and a real-time optimisation algorithm, the solution implements functions that help the crew to increase the vessel’s operational efficiency and reliability.

Vessel performance optimisation testimonials

Speaking about the implementation, Ian Taylor Company CEO Matthew Taylor said: “By the nature of our service, we are an international company. We need to show to the international marine community represented by all ships we help to cross the Magellan Strait, that we are responsible for the safety of operation and environment protection. We also need our crew to be proud of their role in this operation.”

Ian Taylor Company COO Simon Mackenzie stated: “Our biggest challenge is the communication between our offices, located in Valparaiso and the ships operating in areas located between Magellan Strait and Peru. We need to permanently communicate with our ships, the crew to communicate with us, and to make sure the ships are safe and efficient.”

Gustavo Mahuzier, fleet head at Ian Taylor Company, highlighted: “The most important responsibility of our department is the ship capacity to operate safely and efficiently. Since the ships are located in very remote locations, this task is challenging; we needed a system to help us to permanently control in details the ship operation.”

Mr Italo Maritano, consultant from IM Consulting, who led the Chilean team to implement this technology in Chile stated: “We were looking for a system, which can be applied to optimise any type of ship propulsion and, as a result, to increase the ship’s operational efficiency.”

For more information about optimising your ship’s fuel usage, fill out the enquiry form on this page.

Contact Details

Website

Email Address

Address

Laval, Quebec, H7X 3T6,

Canada