PureteQ is an engineering company that specialises in the development, installation, start-up and commissioning of patented high-tech process plants.

The Denmark-based company solves environmental problems for its customers in the offshore and maritime industries.

PureteQ install systems to transform liquid hazaradous waste and industrial by-products into sustainable, clean energy.

The company also constructs technologies to reduce and eliminate combustion and incineration-related issues, such as systems for the treatment of flue gas, exhaust gas and process water, as well as heat recovery systems for flue gas emissions.

High-tech scrubber systems for green shipping

The maritime industry is changing with new requirements relating to energy efficiency and environmental protection coming in to effect.

PureteQ’s patented, high-tech maritime scrubber system can reduce sulphur emissions from shipping and other flue gas emissions to comply with new requirements relating to energy efficiency and environmental protection.

Maritime turbo scrubber system for purifying flue gases

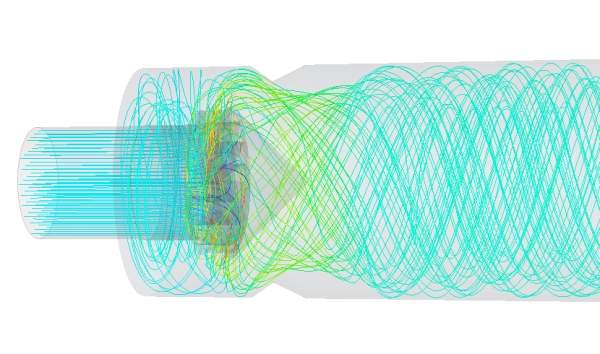

The PureteQ Maritime Turbo Scrubber is a high-tech, composite scrubber system for the purification of flue gas from maritime engines and boilers. Hydrodynamic fluid distribution ensures optimal absorption of sulphuric acid and particles.

The company has developed, manufactured and patented an entirely new scrubber system for the purification of flue gas.

With its hydrodynamic fluid distribution system, the PureteQ Maritime Turbo Scrubber outperforms most traditional scrubber systems in terms of weight, efficiency and built-in options.

A specially designed turbo quench allows for rapid and efficient cooling of gas prior to sulphur oxides (SOx) removal, while the temperature is reduced by more than 75% in less than 0.3s.

IMO and EU legislation-compliant flue gas purifying scrubber technology

New legislation, which comes into force from 1 January 2015, requires all ships in the Europe and Central Asia (ECA) region to use fuels with no more than 0.1% sulphur content, or use alternative methods to achieve the same effect of SOx emissions.

PureteQ Maritime Turbo Scrubber technology is a commercially attractive alternative to costly low-sulphur content distillates and complies with IMO and EU emissions legislation.

How PureteQ’s maritime gas scrubber works

The PureteQ Maritime Turbo Scrubber works in three stages:

- A turbo quench cools the gas: to reduce the gas volume produced by the engine, water is sprayed over the gas via nozzles positioned around the funnel wall. In less than 0.1s the temperature is reduced by 75%

- Wet scrubbing in the scrubber unit: in the scrubber, the gas is again sprayed with water from nozzles positioned in a staggered, three-column formation, depending on specific size and capacity

- Droplet separator: the fluid is forced up the funnel in a spiral pattern, which allows unwashed sulphuric acid and particles to dynamically separate and slide down the sides of the funnel to the base of the turbo scrubber. The sulphurous fluid is then fed for conventional water treatment, including filtration and sludge-tank storage

Benefits of the PureteQ Maritime Turbo Scrubber include:

- Energy-efficiency

- Can be fitted as an in-line or by-pass system

- Easy to install

- Capacity range from 4MW to 20MW

- Weighs 30% to 40% less than conventional systems

- Can be placed horizontally, vertically and diagonally to minimise structural work on retrofit

- Easy maintainence: nozzles can be replaced while the unit is in operation

- High-tech, lightweight composite and alloy scrubber system available

- Hydrodynamic fluid distribution ensures optimal absorption of sulphuric acid and particles

About PureteQ

PureteQ is part of the Dansk Synergi A/S conglomerate, with headquarters, production facilities and a testing centre in Svendborg, Denmark.