GF Piping Systems developed the fire retardant system HEAT-FIT to bring lightweight, corrosion free thermoplastic piping systems onboard vessels and offshore for essential applications.

The demand for thermoplastic piping systems has grown considerably over the last few years. The lightweight, corrosion free, and long-lasting alternative to traditional metal piping systems is the ideal solution to increase the efficiency of your vessel. Thanks to the newly developed fire retardant system HEAT-FIT, thermoplastic piping systems can finally be used for essential applications onboard.

The unique system copes with the strict fire resistance regulations of the International Maritime Organization (IMO) and makes thermoplastic piping systems resistant to flame temperatures of 1.000°C for at least 30 minutes under pressure. Made of durable and flexible materials, the system consisting of co-extruded pipes and fitting jackets can sustain highly demanding marine industry conditions.

The safety of your crew, passengers, and cargo is of the utmost importance. HEAT-FIT allows you to use thermoplastic piping systems, without compromising on safety. The cutting edge solution is ideal to lower the overall weight of your ship, to increase its efficiency, and to reduce maintenance work. HEAT-FIT can be installed in essential (L3) applications on board cruises and ferries, merchant fleets, and offshore platforms and floating wind farms.

Unrivalled reassurance for your crew and vessel in marine applications

Ships are not only floating cities but are also essential for the world’s economy. When using the oceans as traffic and commercial routes, applications onboard have to deal with extreme conditions. Concerning longevity and efficiency, preventing corrosion and installing lightweight solutions are more important here than anywhere else.

As ship sizes increase, construction requirements continue to raise the demand for lightly constructed yet perfectly safe ship systems. As demand rises for more sustainable shipbuilding and operations, more attention is directed towards emission control and ballast water treatment while maintaining passenger security and comfort.

With GF Piping Systems, corrosion is no longer an issue for shipbuilders. The plastic piping systems are non-corrosive and designed to last throughout the ship;s entire service life. Therefore, they contribute to the piping system’s increased reliability while significantly lowering maintenance costs compared to metal. They are excellently suited for applications involving drinking and sewage water, coolants, acids, leaches, and other chemicals, as well as abrasive compounds.

Energy efficiency and recyclability are important elements in lowering the environmental impact of a piping system. Relevant certificates and approvals worldwide accredit our system’s quality, safety, and reliability, including LR (Lloyd’s Register) and DNV. Compared to competitive materials, plastic solutions continue to cause less CO2 emissions and offer a lower ecological footprint, forming the basis for sustainable performance.

Benefits

Based on intumescent technology, HEAT-FIT is designed to cope with the harshest marine environmental condition and brings the benefits of lightweight thermoplastic piping systems to essential applications

Safety

The system fulfils the stringent requirements by IMO and protects thermoplastic piping systems from fire with a temperature of 1000°C for 30 minutes under pressure of 3 bar.

Tested and approved

The system was tested in accredited laboratories and multiple in-house tests and is approved by ABS, BV, DNV, LR, and RINA (for approvals per product, see product ranges).

30% less weight

In combination with the ecoFIT piping system (PE100), HEAT-FIT is the ultra-light alternative to standard metal piping systems, increasing your vessel’s efficiency

Fast and easy installation

The HEAT-FIT system, in combination with the ecoFIT system, is installed within minutes for years of operations. The system is designed for new build and retrofitting and is easy-to-handle and no hot work is necessary

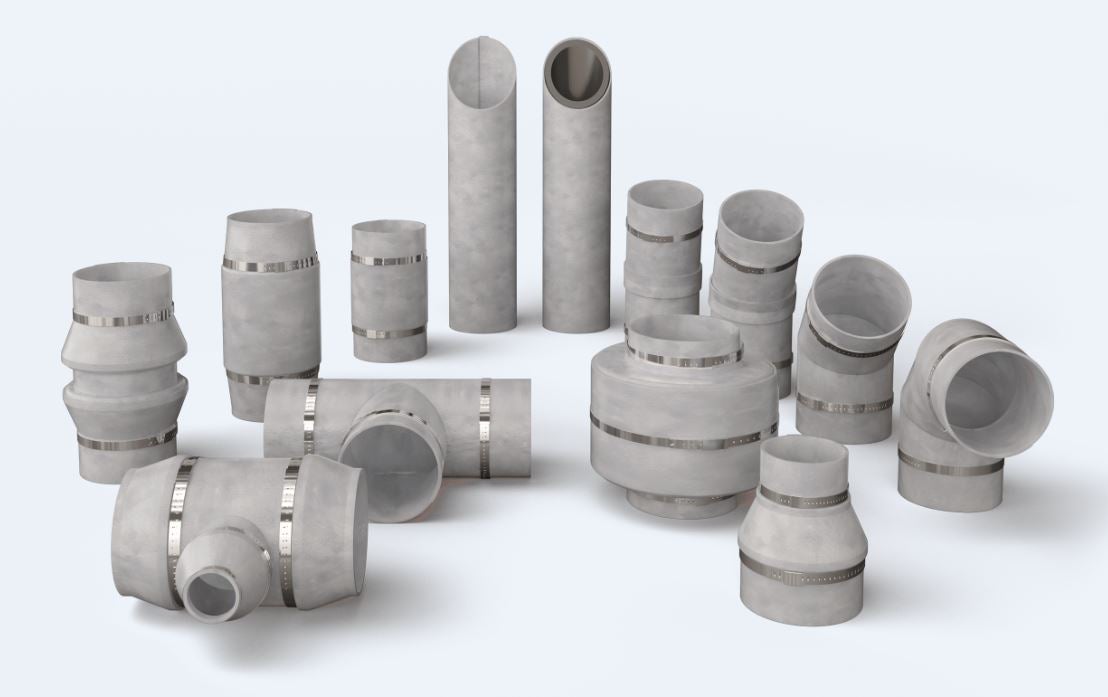

HEAT-FIT system portfolio

With HEAT-FIT, GF Piping Systems offers a unique, top-notch piping system solution for the ultimate fire protection onboard, including pipes, fittings, and tools. The system is available in a jacket version and a co-extruded version.

For more information, download the full product brochure.