The Frank A Shrontz is the first of a series of four new-generation Very Large Crude Carrier (VLCC) tankers, built for Chevron by Samsung Heavy Industries of South Korea.

DESIGN

The Frank A Shrontz has an overall length of 1092ft and a moulded breadth of 190ft. Its depth is 102.6ft and the width of the moulded skin is 11ft at the sidewall and 9.8ft at the bottom. It has a displacement of 350,849t and a gross tonnage of 160,036t.

During trials, the vessel’s average service speed was 16.23kt, which was almost a quarter of a knot in excess of the specified guarantee speed. The tanker has a cruising range of 27,500 nautical miles.

On the port side of the Frank A Shrontz there is a helicopter-landing area. It is capable of handling a Sikorsky S58T with a 20.1m clear zone

CARGO SYSTEMS

The vessel is equipped with five main centre tanks and five pairs of side cargo tanks. There are two slop tanks with aluminium brass heating coils, allowing an increase in temperature of from 20°C to 77°C within 48 hours, when 50% full of sea water. Three grades of cargo can be handled simultaneously. The double hull spaces continue from the storage tanks to surround the bunker fuel tanks aft of the cargo section. The aft bunker tanks are protected by a 2.5m-wide cofferdam. The Frank A Shrontz has a ballast capacity of approximately 99,500m³ including the peak tanks.

The Bergan radar-based cargo tank gauging system features tank pressure monitoring for each individual cargo tank. The facilities allow a maximum cargo loading rate of 18,000m/h through three cargo manifolds with three tanks open in each segregation. The cargo is handled by three Shinko steam turbine-driven cargo pumps. These have a total discharge head of 150m and are rated at 5,000m³/h.

For tank washing, there is a Dasic Marine deck-mounted crude oil washing (COW) system. The two Westfalia 5,000t/h heavy fuel oil and two 4,700t/h light oil purifiers are stored in the same area as the Ssangyong main and auxiliary engine fuel oil pumping and heating units.

PROPULSION

The tanker is powered by a Samsung-MAN B&W 7S80MC Mk Vl engine with a maximum continuous rating of 25,485kW (34,650bhp) at 79rpm. Its fuel oil system uses a 50 micron automatic backwash filtration system based on a Boll & Kirch filter unit. It also has a single Mitsubishi MAC90B double drum auxiliary boiler, which is rated at 90t/h at 16kg/cm². In addition, there is a Kangrim composite boiler with both an exhaust gas and oil-fired section (fired by a Saake burner), which are each rated at 2.5t/h.

Electric power comes from three 980kW Sangyong-Holeby diesel generators which operate at 720rpm. The emergency generator is from MAN-DEMP and rated at 400kW.

The engine drives a Hyundai four-bladed FP propeller. The tanker is steered by a Samsung-Hatlapa conventional dual ram system.

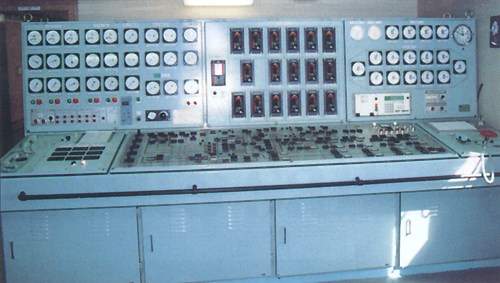

AUTOMATION AND CONTROL

Most engine and machinery control functions are carried out using a Samsung/STN Atlas Elektronik main engine control system. The main plant machinery is monitored using a Samsung Electronics dual CPU-based system. The Kyma ship performance monitoring assembly includes fuel flow meters, shaft torquemeter and computer work station.

The Litton navigation system incorporates a dual C Plath gyrocompass, Sperry voyage management system and autopilot and two Decca radars. There are two sets of differential GPS navigators, speed log and Sperry Voyage Data Recorder. The tanker has GMDSS area A3 radio equipment, with two VHF radio systems, Inmarsat B and C satellite communications terminals and MF/HF radiotelephone with telex and suite.