The Normand Pioneer came to the attention of the world’s media in August 2000 when it was used to transport diving equipment to the Barents Sea to assist attempts to reach the Russian submarine, the Kursk. The Normand Pioneer also represents a pioneering design, combining a wide range of capabilities in a 95m-long and 24m-wide vessel.

The vessel was designed by Ulstein Ship Technology, who worked closely with owners Solstad Rederi in the vessel plans. Normand Pioneer was delivered in February 1999 and chartered to Coflexip Stena Offshore. During its five year charter it was due to carry out ploughing and pipe-laying work for Saga Petroleum and Statoil, among others. The vessel flies the Isle of Man flag and has Det Norske Veritas classification.

DESIGN

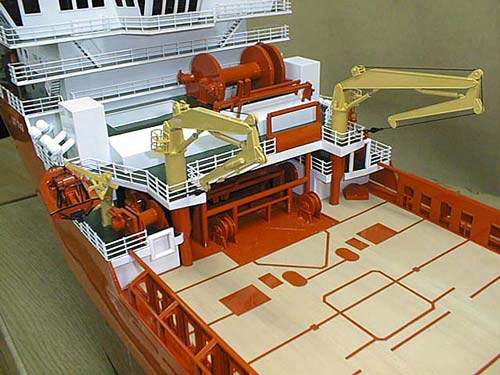

The new UT742 design used for the Normand Pioneer incorporated the owner’s requirements for a multifunctional offshore vessel capable of trenching, flexible pipe-laying, towing and anchor handling. The design has given the vessel roughly 280t bollard pull. The working deck area is almost 1,000m² and can carry about 3,500t with its centre of gravity 1m above the deck out of a total of 5,300dwt. Due to this, up to 2,500t of top side equipment for trenching, pipelaying and other subsea or drilling work can be installed.

Twin monopools run through from the bottom to the main deck. The aft one measures some 7m² and is designed for pipe-laying, while the forward one is 4.5m² and can be used for the deployment of inspection class remote operated vehicles. The moonpools are fitted with baffles to prevent seaspray reaching the deck.

The vessel’s winch can pull 500t and has a capacity for 1,500m of 109mm wire. Twin tow drums each hold 2,000m of 83mm wire.

In building the Normand Pioneer, the yard utilised its method of modularising work flow to improve work efficiency. On the vessel, four modules were located in the engine room and three aft. By prefabricating modules, as much activity as possible is shifted from the engine room to the workshops. This method of pre-outfitting does require greater attention to planning and timely delivery of components.

PROPULSION

Normand Pioneer is powered by one eight-cylinder and one six-cylinder Wärtsil SW38 engine. This converts to a respectable 27,800bhp. The vessel has two tunnel thrusters and an Azimuthing thruster forward, and two tunnel thrusters aft.