An energy-harvesting device capable of capturing all chaotic motion and turning it into useable power could be used on commercial ships in the relatively near future to increase efficiency and reduce dependence on fossil fuels.

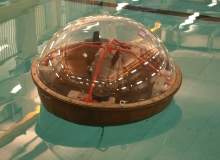

The ‘WITT’ device(‘Whatever Input to Torsion Transfer’) bobs, swings, rocks and rolls to collect motion in any direction – clockwise, anti-clockwise, up, down, back and forth – and transfers it to a flywheel to create power. In the context of the shipping industry, the WITT would allow ships to harness power from the sea by capturing wave movement.

“Few devices currently exist that can take all of the motion that’s in the sea – whether it’s very big waves or choppy up and down conditions – and turn it into useable power,” says WITT Energy’s managing director Mairi Wickett, whose husband Martin Wickett, a civil engineer, came up with the concept for the device five years ago.

From workshop to worldwide stage: WITT’s journey so far

The first prototype was built in Martin’s workshop in 2009 from off-the-shelf components and, since then, the Wicketts have been working hard to build up WITT Energy. The company now has a product development manager, a finance manager, a corporate lawyer and a liaison manager, all of whom are fully focused on getting the technology in front of the right people so it can be further developed and scaled up to be used in industries such as renewable energy harvesting and shipping.

Fast approaching the 150th anniversary of its opening, the Suez Canal has witnessed many key events in Egyptian history.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataLast year, their work started to pay off. In July, following the successful testing of the device in the Wave Tank at Plymouth University, the WITT team won a £190,000 development grant from the UK Technology Strategy Board.

The resulting project, Energy Harvesting Technology from Vessel Motion, is being led by A&P Shipping and aims to demonstrate the capability of the WITT system to capture ‘pitch and roll’ motion and turn it into power, reducing the amount of fuel ships need to use for normal day-to-day tasks. A marine version of the device, created by Devon-based company Supacat, is currently being tested by the University of Exeter in their Dynamic Marine Component Test Facility (DMac).

In October, WITT Energy’s device also scooped the $100,000 Gulfstream Navigator Award from the Ocean Exchange, an international organisation that promotes the adoption of technologies that positively impact the environment, economics and health.

And since then the WITT team has been catapulted into the spotlight. “The next day, we were on Reuters and major press release sites and it’s had this kind of ripple effect,” Wickett recalls. “We’re getting feedback from all over the world and we don’t even know where they heard about us!”

Why are shipping companies interested in the WITT device?

One of the key reasons for the shipping sector’s interest in the WITT is the scalability of the device: it can be absolutely tiny, extremely large or anywhere in between. Of course, when it comes to crude oil containers and transport vessels, bigger is better, as the WITT team discovered when A&P Shipping took them on a tour of two of their docked vessels earlier this year.

“The size of the crude oil container’s engine was bigger than a double decker bus and our device would be around 20% smaller than the size of a car,” Wickett says. “It would have seriously heavy pendulums, and has the potential to generate hundreds and hundreds of kilowatts of power.”

Secondly, the self-contained nature of the device is attractive for marine operators. As it is completely enclosed and none of the parts are exposed to the elements, it can be used in the planet’s harshest environments without any concerns – a ‘fit and forget’ solution. It will also be built with industry standard components.

“The sea is savage and this device, unlike anything else in the renewable energy sector, doesn’t have blades or pieces going up and down. We’ve been informed by very established people in the sector that anything with protruding parts gets smashed to pieces, but our sealed units will be very robust with all the working components inside the sealed unit,” Wickett explains.

The device creates zero environmental impact and works 24-7, unlike its wind or solar-powered counterparts.

What’s next for WITT and the shipping industry?

For an industry focused on reducing emissions, this technology could certainly play a role. Shipping currently accounts for around 3.3% of the world’s man-made carbon dioxide emissions, and more and more regulations are coming into play every year, including the IMO’s Energy Efficiency Design Index (EEDI), which took effect in January 2013 and forces new ships to meet a minimum level of energy efficiency.

“Ships can use the power for whatever they want,” Wickett says. “We visited a ship transporting fresh produce in refrigerated units from Africa to the UK and they need power for their refrigeration systems. But the power could also be used for the opposite purpose. For example, if you were in the Arctic, you could use the excess power that you’re getting from the pitch and roll to offset heating costs within the vessel.”

The team is still taking a cautious approach to development, however. “We want to ‘aim small, miss small’,” Wickett admits, noting that WITT Energy intends to kick off – once testing is complete – by developing commercial devices for navigational buoys, data-gathering buoys and small vessels.

“It will be the WITT unit, a pendulum and a power generation system,” Wickett explains. “This will easily fit in existing navigational buoys and other similar vessels. We will be able to retro-fit these devices, so it will be a simple exercise.” The first commercial products should be ready for testing by autumn 2014.

Following the launch of the first WITT products, the team believes it will be much easier to show shipping companies the benefits of this energy-harvesting technique. Work has also begun on constructing the devices in a range of different sizes. “We are now in talks with a UK engineering company, which has 40 years’ expertise in transmission manufacturing, to design, build and manufacture the WITT in several sizes. A&P Shipping will then test the device over several months, with an energy analysis showing the potential for fossil fuel savings,” Wickett says.

The company may be looking to ‘aim small, miss small’, but there’s no doubt that the potential for a scaled-up WITT device is anything but.