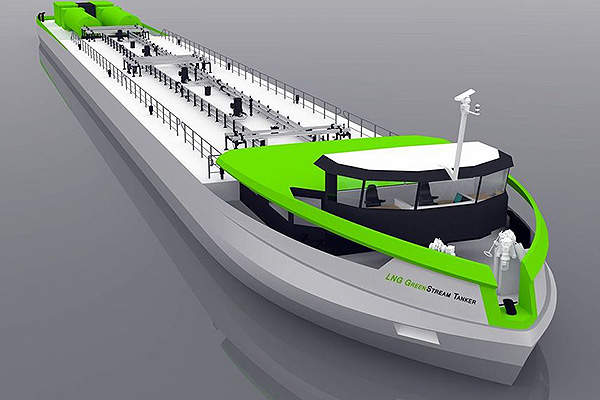

LNG Greenstream is the first of two liquefied natural gas (LNG)-powered barges being built by Peters Shipyards in Kampen, Netherlands. The two barges are chartered by Shell to transport liquid fuels along the Rhine River. The barges are the first of their kind for Shell and the inland marine industry. Dutch company, Interstream Barging (ISB), will manage the barges.

The two inland vessels were ordered in 2012. LNG Greenstream was launched in March 2013 and delivered to Shell in April 2013. The second vessel, Greenrhine, was christened in September 2013.

The gasoil-free, LNG tankers are designed with advanced safety and efficiency features, and will operate in the Netherlands, Belgium, Germany and Switzerland.

LNG Greenstream design

Related content

Prelude Floating Liquefied Natural Gas Facility, Australia

The 2,877dwt inland tanker has six cargo tanks with a capacity to carry 3,124m³ of mineral oils and chemicals.

The LNG Greenstream is a fully electrically-powered LNG barge incorporating a double hull built of mild steel. She has an overall length of 110m and beam of 11.4m, while the length between perpendiculars is 109.5m and draught is 3.46m.

The 2,877dwt inland tanker has six cargo tanks with a capacity to carry 3,124m³ of mineral oils and chemicals. The impact-resistant IJsselhuid shell plating allows for provision of larger cargo tanks. The U-shaped ballast tanks in the tanker shield the cargo tanks from impact on the sides or the bottom.

The wheelhouse is distinctly placed at forward of the hull for better trim and weight distribution. The design is relatively safer as the crew’s ahead vision is less obstructed.

Propulsion details of the LNG Greenstream tanker

The electric propulsion system of the LNG Greenstream is accredited not only for its lower fuel consumption, but also for its increased safety and redundancy. The propulsion system reduces the carbon dioxide and nitrogen oxide emissions by 25% and 80%, respectively. Further, no sulphur oxide and particulate matters are discharged.

The propulsion system includes four LNG-powered spark-ignited engines producing 285kW each. The Scania-Sandfirden engines, supplied by Sandfirden Technics, are mounted in pairs of modules on the aft deck.

The four small engines offer load-sharing during the course of the journey. Each module, including two generators and other equipments, forms the LNG pack, which can be easily unfastened and shipped to workshops for maintenance, thus reducing the vessel’s downtime from a week to half a day.

The propulsion is provided by two electrically-powered VZ-550, Z-drives generating 500kW of power, and a 2-K-1000 Veth-Jet bow thruster. The azimuthing thrusters with a single propeller located in the nozzle form v-shaped frames. The placement provides optimum utilisation of the aft ship sections in shallow waters. The thrusters also assure great maneuverability eliminating the need for separate rudders.

Fuel storage system onboard the LNG Greenstream

The LNG tanks are conveniently placed on the deck of the ship. The tanks hold the natural gas in liquid form at a pressure of 43.5psi and a temperature of -160°C. Each 40ft container has vacuum-filled double walls to minimise heat transfer. The liquid fuel is converted back into gaseous form by a heat exchanger before being used in engines.

Greenstream LNG vessel accommodation

The vessel has two captain’s cabins on the main deck and three crew cabins on the lower deck, one of which has an ensuite bathroom. A laundry and a dry store are also placed on the lower deck.

The living room has an open kitchen, a dining table and a settee on the main deck, and provides a view of the aft deck through the frameless windows spanning the entire width.

LNG Greenrhine details

The sister vessel, Greenrhine, was built on the same lines of the LNG Greenstream. It is also a double-hull mild steel type with a dead weight of approximately 2,800t and gross tonnage of 3,130t. The two LNG-powered tankers together are set to be the future of inland navigation in the areas of feasibility, assurance and adaptability.