Revolutionising sanitary automation processes and securing safe drinking water supply

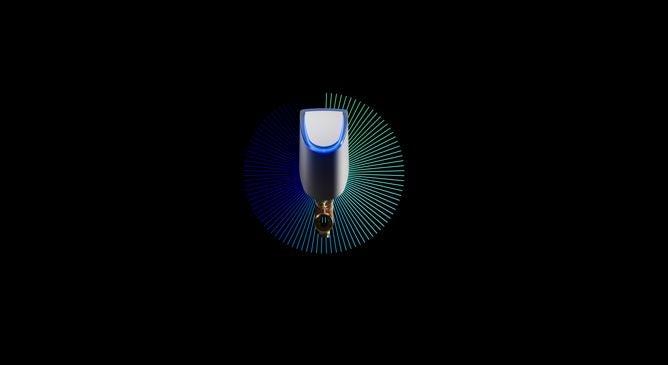

The Hycleen Automation System by GF Piping Systems offers a sophisticated package for the automation of drinking water installations.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

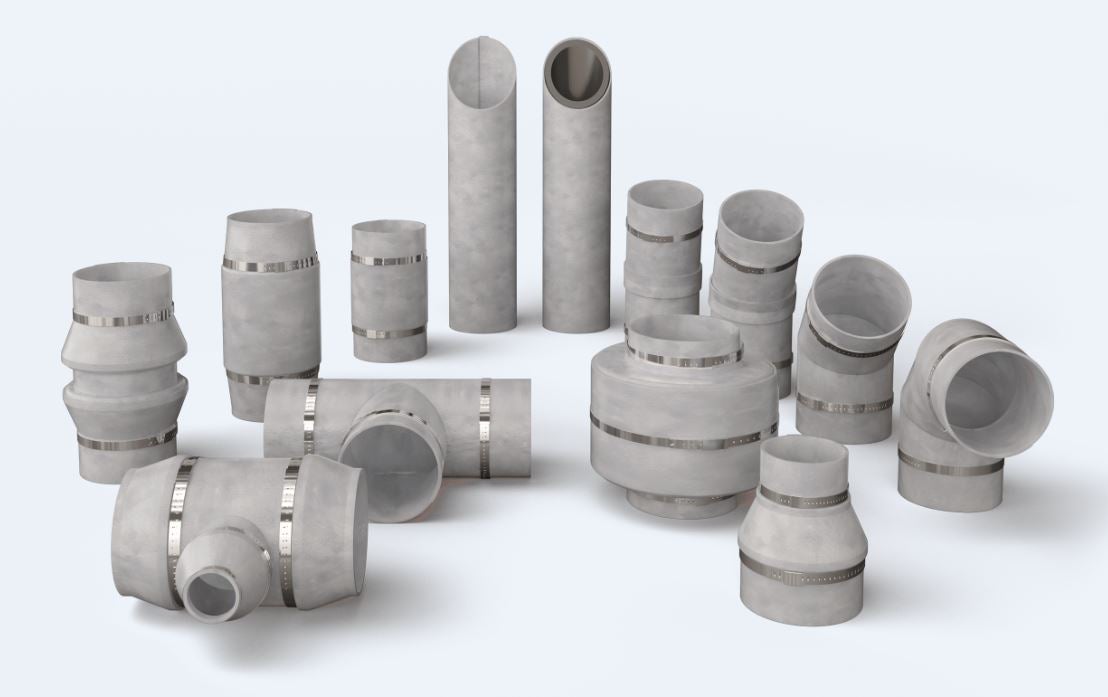

Georg Fischer (GF) Piping Systems offers thermoplastic solutions for the safe transport, supply, and treatment of water onboard ships. The company provides marine-approved and high-quality, wear-resistant flow solutions, including thermoplastic pipes and fittings, valves, actuation, measurement and control devices, jointing technologies, design and engineering support, customisation, and offsite manufacturing offers.

GF Piping Systems’ products are available in various materials, such as ABS, PVC-U, PVC-C, Polybutylene (PB), Polyethylene (PE), Polypropylene (PB), or multilayer materials, and cover a broad spectrum of operating temperatures, dimensions, and nominal pressures. This allows customers to find the best solution for their individual needs.

With 36 production facilities, as well as sales representatives and consultants in 100 countries worldwide, GF Piping Systems can help customers with every step of a new build or retrofit project, from planning to commissioning. The company’s sustainable solutions for maritime applications, combined with its specialised engineering, offsite prefabrication, and training programmes, ensure that all projects are smoothly implemented.

GF Piping Systems develops application-oriented thermoplastic piping solutions that enable fast and easy installation, profitable operations, and environmental benefits. The company supports its customers in implementing sustainable, future-oriented, and well-designed piping concepts by using state-of-the-art planning techniques to optimise the economic efficiency of processes. The lightweight piping systems can be used for the transportation of water, seawater, coolants, and sewage onboard all types and sizes of ships, including cruise liners, ferries, mega-yachts, container ships, bulk and LNG carriers, OSVs, wind farms, and offshore energy platforms.

Plastic piping systems cover a wide range of fluid applications onboard ships and remain non-corrosive for the entire service life of the vessel (with an expected service life of 25 years). They are robust and can withstand the harshest conditions at sea, without compromising on safety. Unexpected leakages and the resulting repair and maintenance work are therefore reduced.

In comparison to traditional metal piping systems, thermoplastic solutions are up to 60% lighter. By saving weight, ship owners and operators can reduce their fuel consumption and costs while also reducing greenhouse gas (GHG) and CO2 emissions during the entire lifetime of the vessel.

High water and fluid quality is always certain, with exact measurements, leak-tight systems, and the best jointing technologies. GF Piping System’s drinking water solutions reduce the risk of bacterial pathogens in staff and passenger cabins.

The high flexibility of the material and the easy installation technology help to keep installation costs and times to a minimum. GF Piping Systems provides not only the piping systems but also the tools and training to help crew members quickly install the pipes onboard ships and in prefabrication units.

To help save time and reduce the maintenance costs of the piping systems, GF Piping Systems makes process automation easy and simple to set up. Using valves, actuators, and measurement and control devices, processes onboard vessels and offshore energy platforms can be automated to improve efficiency.

The marine portfolio of the company’s plastic piping systems, including pipes, fittings, valves, and tools, meet the requirements of the International Maritime Organization (IMO) and are approved for essential and non-essential applications by ABS, BV, CCS, DNV, NK, LR, RINA, and many more. For more details, please contact a Georg Fischer marine representative.

For rapid, reliable, and high-quality jointing in condensed spaces, GF Piping Systems provides jointing technologies, including electrofusion, butt fusion or infrared fusion (IR). When jointing thermoplastic materials, no hot work is required, which makes installations up to 50% faster.

GF Piping Systems’ instructional courses help clients to teach their customers and installers the essential knowledge necessary for welding pipes and piping components. The courses also provide an in-depth understanding of butt and electrofusion connections. Training can be delivered either virtually, in-house, or onsite, providing customers with additional flexibility.

GF Piping Systems’ specialised customisation teams help to create tailored solutions to fit any situation. Working with the customer, the teams can carry out individual consults and off-site prefabrication. They can also develop custom-made parts to complete existing systems or create special solutions produced in small series. Through its global network of flexible locations, the company offers a wide range of comprehensive solutions that can be adapted to fit any situation.

GF Piping Systems is a division of the Georg Fischer Group, which also includes GF Automotive and GF Machining Solutions. Founded in 1802, the corporation is based in Schaffhausen, Switzerland, and serves customers in more than 100 countries. GF Piping Systems has its own sales companies in 31 countries, which means it is always by its customers’ side. Production sites in 36 locations in America, Europe, and Asia ensure sufficient availability and quick, reliable delivery. In 2022, GF Piping Systems generated sales of CHF2,160 million and employed 8,085 people.

The Hycleen Automation System by GF Piping Systems offers a sophisticated package for the automation of drinking water installations.

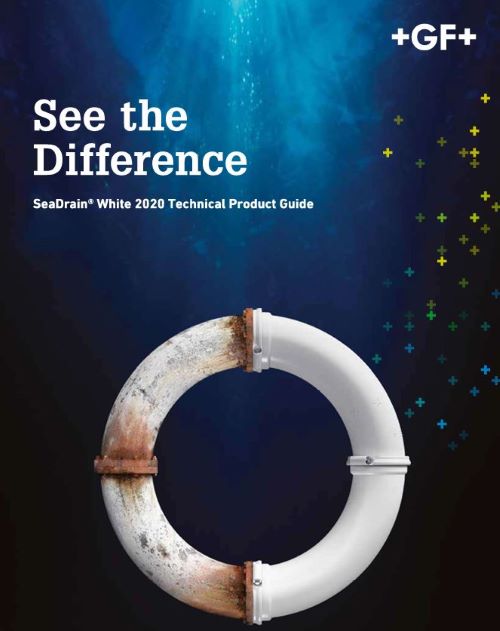

See the difference above and below the line with the GF Piping Systems SeaDrain White range.

How pre-insulated plastic piping systems help to reduce CO₂ emissions and costs for shipowners and operators.

The route to decarbonisation.

GF Piping Systems signed the contract with China's famous Shanghai Waigaoqiao Shipyard (SWS) for the supply of Sanipex MT, Instaflex, ecoFIT and SeaDrain® White pipes and fittings, as well as on-site training, installation, quality control, and assurance for Cruise Project H1509, the largest luxury cruise ship ever built in China by SWS.

HEAT-FIT is designed to bring lightweight, corrosion-free, and efficient thermoplastic piping systems to essential applications onboard ships.

Chen will focus on developing and implementing a commercial strategy to identify new business opportunities for the Swiss flow solutions provider in Asia, increasing customer proximity.

With the addition of the new valve, the Swiss flow solutions provider has completed its portfolio of the lightweight and corrosion-free Butterfly Valve 565. Its lug-style design allows for additional use cases in water applications in industries such as water treatment, marine, and cooling applications.

Nor-Shipping takes place in Oslo, Norway, from 6-9 June 2023.

The demand for thermoplastic piping systems has grown considerably over the last few years. The extensive use of plastic piping can make ships more efficient while reducing costs.

SeaDrain White marine drainage pipe system for black and grey water drainage, is lighter in weight, lighter on maintenance requirements, lighter on installation time and labour, and lighter in lifetime system costs than competing metal systems.

Georg Fischer (GF) Piping Systems will be exhibiting its range of corrosion-free piping solutions for ships at this year’s Seatrade Cruise Global event.

Defying industry challenges.

Ultimate fire protection.

Embrace the cold.

See the difference.

Automatic control and monitoring of drinking water installations.

State-of-the-art drinking water installation.

Beats metal in every round.

GF Piping Systems developed the fire retardant system HEAT-FIT.

COOL-FIT increases the efficiency of your cooling circuit and is a more sustainable alternative to metal piping systems.

Our teams develop application-oriented thermoplastic piping solutions for essential- and non-essential applications to enable fast and easy installation, profitable operations, and environmental benefits.

We make piping systems, but it's much more than that.

Plastic Butterfly Valves have already proven to outperform metal valves in almost every way, thanks to a higher resistance against corrosion and a lighter weight. Now, a new generation has arrived to beat metal in cost-effectiveness, too.

SeaDrain® White is the new best in class piping system solution for black and grey water applications in marine passenger vessels.

For maximum hygiene and operational safety, the international charity Mercy Ships selected ecoFIT, INSTAFLEX, and PVC solutions by GF Piping Systems for various water applications on board.