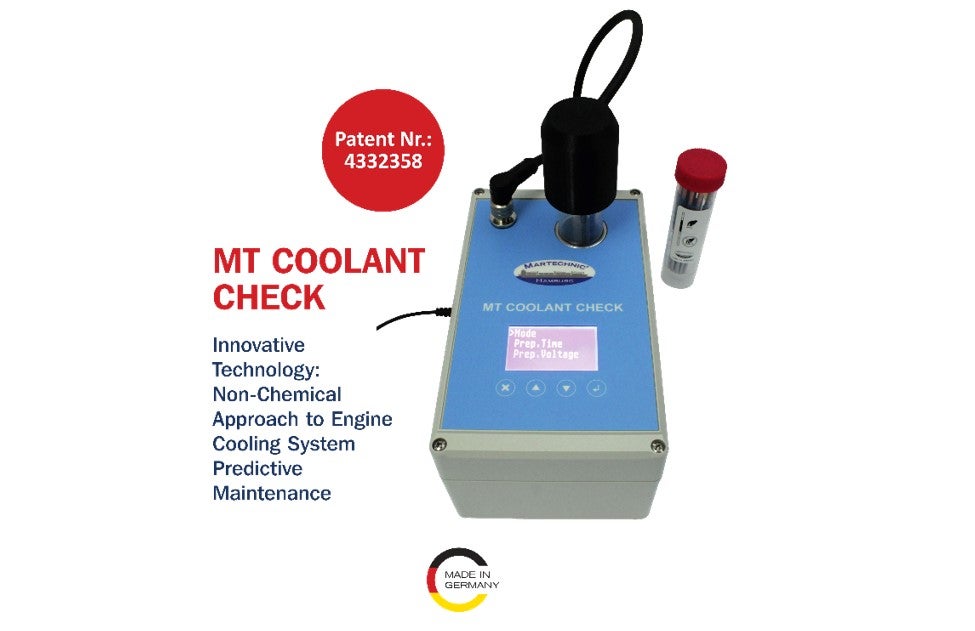

Martechnic is Granted European Patent for Its Innovative Test Device MT COOLANT CHECK

Martechnic is honored to share that our innovative test device MT COOLANT CHECK has recently been granted a European Patent Nr. 4332358 for utilising a chemical-free, environmentally friendly and sustainable measurement method to assess the remaining corrosion protection of the engine coolant directly on board a vessel.

Our patented technology evaluates water-based engine coolants by means of an electrotechnical apparatus with constant (corrosion resistant) and working/changeable (corrosion-prone) electrodes running just one single test. The electrodes are subjected to corrosion stress in a simulated engine cooling system. The performance of the engine coolant is characterised in relation to its existing level of corrosion protection on the metals used in the cooling system. Thereby, the remaining corrosion protection of the engine coolant in use is determined with a new unit of measurement: Lagner (lag).

After the fully-automatic 20 minute evaluation, the test device offers precise and timely maintenance recommendations. Should the anti-corrosive effect of the engine coolant in use be insufficient, the MT COOLANT CHECK automatically calculates the dosing rate of the chemical additive to be added. In this way, unnecessary coolant changes and wastage can be avoided.

The significant benefit of our technical solution is its applicability for testing and analysing different coolant formulations regardless of the coolant additive composition or manufacturer.

Easily recyclable electrodes with no shelf-life limitations contribute to waste reduction, minimising environmental risks, especially to marine ecosystems, thereby marking a significant stride towards sustainable predictive maintenance in the maritime industry.

The recently issued patent for the test device MT COOLANT CHECK adds to Martechnic’s intellectual property portfolio that includes the test device TOTAL IRON CHECK and the water-in-oil sensor technology AHHOI IR.

To find out more about our new testing equipment, please click here.