Crucial Oil Quality Check

Most contamination of lube oil is through water that causes problems and damage in machines and engines.

For 25 years, Martechnic has designed and developed oil test and analysis equipment to support the smooth running, optimal and reliable performance, and cost-effective maintenance of on-board machinery.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Martechnic specialises in oil quality management and provides engineers and users with on-site analysis equipment for condition monitoring of lubricant and hydraulic oil, such as marine distillate and marine residual fuels.

Crucial oil parameters can get measured either regularly with the help of portable oil test devices and test kits or on a continuous basis employing permanently installed advanced sensor technology.

The key advantages Martechnic offers its customers include quick and precise information on any occurring changes or abnormal processes in the engine oil condition, effective decision-making on corresponding actions, as well as proper oil system predictive maintenance and the possibility to ensure optimal performance of critical machinery.

Fast and individual response, customer-specific applications and tailor-made solutions, efficient order processing and comprehensive logistic support relate to Martechnic’s principal business lines.

A variety of portable test devices and test kits is developed and designed by Martechnic to check directly on-site and beyond laboratory practice such essential parameters of lube and hydraulic oil as water-in-oil, alkalinity reserve (BN, TBN), viscosity, density and contamination with insoluble or metal particles.

Regular verification on the basis of trend analysis enables early detection of irregularities in the oil condition. Quick and accurate test results with possibility of immediate assessment help to effectively implement condition-based maintenance programs.

To support vessels with their own on-board oil analysis laboratory, Martechnic supplies a Fuel and Lube Oil Test Cabinet, which contains a selection of portable test devices for easy and fast condition analysis of all principal parameters of fuel, lube and hydraulic oil.

Owing to instant availability of test results, the quality of the delivered bunker fuel and the condition of lubricants and hydraulic oil in use can be regularly monitored and promptly evaluated. This helps to ensure the smooth operation of constituent engine parts as well as provides immediate decisions regarding maintenance, including the possibility of prolonging maintenance intervals.

Accurate results of oil condition analysis imply the availability of representative oil samples. Martechnic offers a full range of sample bottles, cubitainers, drip samplers and sampling kits elaborated for safe collection, retention and transport of representative samples of fuel, lube and hydraulic oil. Sampling bottles differ in size, shape and material depending on the oil to be tested.

All sampling equipment for fuel oil samples is in compliance with MARPOL Annex VI requirements. For collection of primary bunker fuel samples during bunkering, Martechnic supplies manual-valve drip samplers equipped with cubitainers which are attached and reliably protected from tampering and contamination through the special sealing system. Safe storage of retained fuel oil samples is achieved by means of a combination of sampling bottle, proper label made of tear resistant and tamper proof material and individually numbered sealing.

Martechnic’s Sampling Kit is a vacuum hand pump with a flexible tube coupled with an adaptor at a sample bottle. The kit is suitable for sampling collection from different parts of the oil tank, and can be applied to determine free water in the oil tank and possible ongoing friction processes.

Undetected changes in condition of lubricating and hydraulic oil can cause malfunctions in machinery systems. Installation of on-line or in-line sensors provides continuous 24/7 monitoring of essential oil parameters and enables real-time detection and tracking of any occurring changes.

Martechnic has developed a Modular Monitoring System, which encompasses various sensors (viscosity, particle, humidity, FE and water-in-oil sensors) and due to its modular design can be installed in accordance with individual customer-specific application needs.

On-board a vessel, the sensors can be installed for controlling the oil condition in generators, main engines and hydraulic systems. The possibility to set an individual alarm level for each oil parameter under surveillance enables an immediate warning as soon as the critical range is reached, allowing immediate corresponding actions and determination of the root cause of the problem.

All the sensors can be connected with the all-purpose display and data processing unit Datalogger for easy recording, transmitting, displaying, reading and storing of the data.

For continuous monitoring of absolute content of water in lubricants Martechnic has developed the AHHOI – Infrared Water-in Oil Sensor. Installed in the bypass, the sensor measures water molecules present in oil up to 10,000ppm / 1.0% vol. irrespective of the state of water: saturated, emulsified or free. The sensor can be used in a combination with a manifold for monitoring the condition of up to four engines (for example the main engine, hydraulic systems or stern tube seals).

Martechnic offers ultrasonic cleaning tanks, generators, submersible transducers and cleaning liquid for safe, thorough and efficient cleaning of different engine parts (for example, cylinder covers, coolers, valves, lube and fuel oil filters) and in particular difficult-to-reach areas. Alongside standard sizes, customized options can be ordered.

Most contamination of lube oil is through water that causes problems and damage in machines and engines.

Internationally recognised standards on protection of marine environment and the corresponding legislation adopted by the US Environmental Protection Agency (EPA) in 2013 'vessel general permit' (VGP) limit the application of traditional mineral based oils for vessels entering the US waters and establish instead the necessity of use of environmentally acceptable lubricants for machinery parts below the waterline (such as stern tube bearings, thruster gearboxes and horizontal stabilisers).

The paper offers the practical example of trend analysis application with regard to two monitoring methods of water-in-oil concentration: regular (with improved and upgraded portable test device TWIN CHECK 4.0) and continuous (with advanced infrared sensor AHHOI).

Martechnic® offers a range of mineral oil test kits that allow clients to promptly test and evaluate fuel, lube and hydraulic fluids on-site.

Martechnic® designs and develops innovative technical solutions, including equipment and services for conducting continuous and preventive maintenance of critical parts of various engine systems.

This white paper focuses on the first experiences with new types of VLSFOs and several problematic issues related to fuel oil quality. Martechnic explains why the application of portable, on-board oil analysis equipment can be regarded as a reliable solution in supporting on-board fuel testing strategy, in order to effectively manage new VLSFO batches.

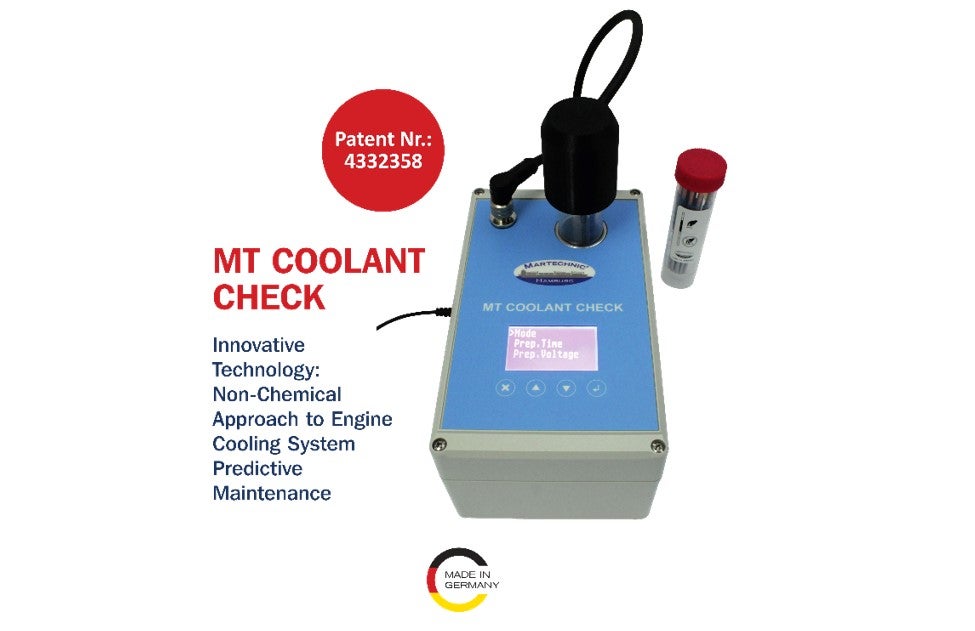

Our patented technology evaluates water-based engine coolants by means of an electrotechnical apparatus with constant (corrosion resistant) and working/changeable (corrosion-prone) electrodes.

We are excited to announce that Martechnic, a leading expert in oil quality management, will be exhibiting at the most premiere maritime exhibition in China - MARINTEC CHINA 2025.

The focus of the summit will be the latest advancements in ship navigation, voyage optimisation, and maritime sustainability.

At the trade show, Martechnic will be exhibiting at the German Pavilion, Booth K11, Hall No. 6.

As a leading expert in oil quality management, Martechnic will be showcasing its innovative technical solutions designed for regular on-board condition monitoring of fuel, lube, hydraulic oil, and engine cooling water.

Martechnic customer relations manager Dr. Frank Bernier will be representing Martechnic and exhibiting at Stand J10, Hall 5.

As a leading expert in oil quality management, Martechnic will be presenting a wide range of its well-established technical solutions for the on-board condition monitoring of fuel, lubrication, and hydraulic oil.

The annual event for purchasing professionals of the global maritime industry will be returning to Hamburg on 10 April 2025 at The Empire Riverside Hotel.

Martechnic is happy to announce the launch of a new test kit “MT UREA CHECK” for rapid on-board determination of urea concentration in marine diesel exhaust fluid (DEF) AUS 40 (aqueous urea solution at 40 % concentration).

Martechnic will be exhibiting at Hall 7, Stand 7C10 together with our long-term business partner and our representative in Türkiye – ESMS.

As 2024 is quickly coming to an end, we are proud to share Martechnic's remarkable achievements.

SMM 2024 is focusing on the topics of decarbonisation and the sustainable development of the shipping industry.

Posidonia serves as an excellent platform for leading Greek and international shipowners, shipping executives and wider maritime professionals to address a variety of issues.

Martechnic will be showcasing its brand-new, patent pending test device MT COOLANT CHECK.

Being an expert in oil quality management for more than 25 years, Martechnic manufactures and supplies portable testing equipment for on-board condition monitoring.

Martechnic is excited to announce its participation in Europort 2023 and is inviting its customers and long-term business partners to visit its team at Hall 7, Booth 7015.

Martechnic will be showcasing its innovative technical solution MT COOLANT CHECK.

The MT COOLANT CHECK utilises electrotechnical apparatus with constant (corrosion resistant) and working (corrosion-prone) electrodes.

Martechnic is delighted to showcase its innovative patent pending product 'MT COOLANT CHECK', developed and designed to regularly monitor the engine coolant condition.

The IMPA Procurement and Supply Chain Conference will be held in the Hamburg Chamber of Commerce for the second time.

As a small family-owned business in Hamburg, Martechnic has always been an exhibitor at SMM.

Regarding the challenges which the global maritime community is currently experiencing, Martechnic considers Posidonia as a unique platform for all international maritime stakeholders to provide dialogue and network possibilities to discuss key themes.

The cornerstone of our business’ philosophy for the past 25 years has been offering engineers, technical maintenance personnel, and end-users innovative oil analysis equipment for on-site applications.

Martechnic will be showcasing its products at the East Med Marine and Oil and Gas Exhibition taking place this year in Limassol, Cyprus.

Martechnic provides oil quality management products for lubricant and hydraulic oil, including marine distillate and residual fuels.

The first MEERKONTAKTE exhibition Maritime Cluster Norddeutschland is taking place in Kiel, Germany, on 8-9 November and Martechnic will be exhibiting.

In 1997 began the successful story of Martechnic. Founded by today's managing director Ingo Herholdt, at Schnackenburgallee in Hamburg, the company grew rapidly, so that they moved to the current location, Adlerhorst 4. Meanwhile, his son, Frank Herholdt, has joined the management.

Like last year, Martechnic© will be part of the Marine Maintenance World Expo taking place in Amsterdam from 6-8 June 2017. The trade fair and conference is a meeting place for companies dealing with international maintenance and repair technologies in shipping. Mr. Herholdt from Martechnic© and their partner Goltens Group are looking forward to your visit at booth 4020.

From 6 to 7 April 2017, Martechnic is traditionally exhibiting at the specialized marine technical trade show in the Eastern Mediterranean - the 8th East Med Marine and Oil & Gas Exhibition in Limassol, Cyprus.

Starting from November 2016, Martechnic is officially appointed as an authorised agent of the Goltens Group on the German market. Taking this new step, the Hamburg-based company further broadens the spheres of its business activities in the oil quality management and condition monitoring of fuel, lubricating and hydraulic oil and adds to its profile the representation of Goltens' on-site services of diesel engines and related equipment.

From 31 October to 2 November 2016, Martechnic® will attend the largest exhibition of the international shipping industry in the Middle East area - the Seatrade Maritime Middle East in Dubai, UAE. The company will share the joint stand of its regional business partner of many years - the M.I.E. Overseas and would like to invite all visitors and participants to attend the stand L13.

This year SMM, the leading international trade fair, had its main focus on innovative technical solutions, and in particular digital transformation for the maritime sector. In the context of difficult market situation and current challenges faced by global shipping industry, automation and digitalisation are regarded as potential long-term benefits which the concept of 'Industry 4.0' offers.

As a preview to SMM 2016 and its special theme 'Digitalisation' Martechnic® is ready to present its newly developed Industry 4.0 concept in the area of portable test devices for on-site quality management of fuel, lube and hydraulic oil. This year the company has been focusing on digital technology development and will be showcasing its two new smart products at SMM.

Martechnic® is a leading expert in the area of oil quality management and offers engineers, ship operators and users effective technical solutions for direct on-site monitoring of fuel, lube and hydraulic oil condition.

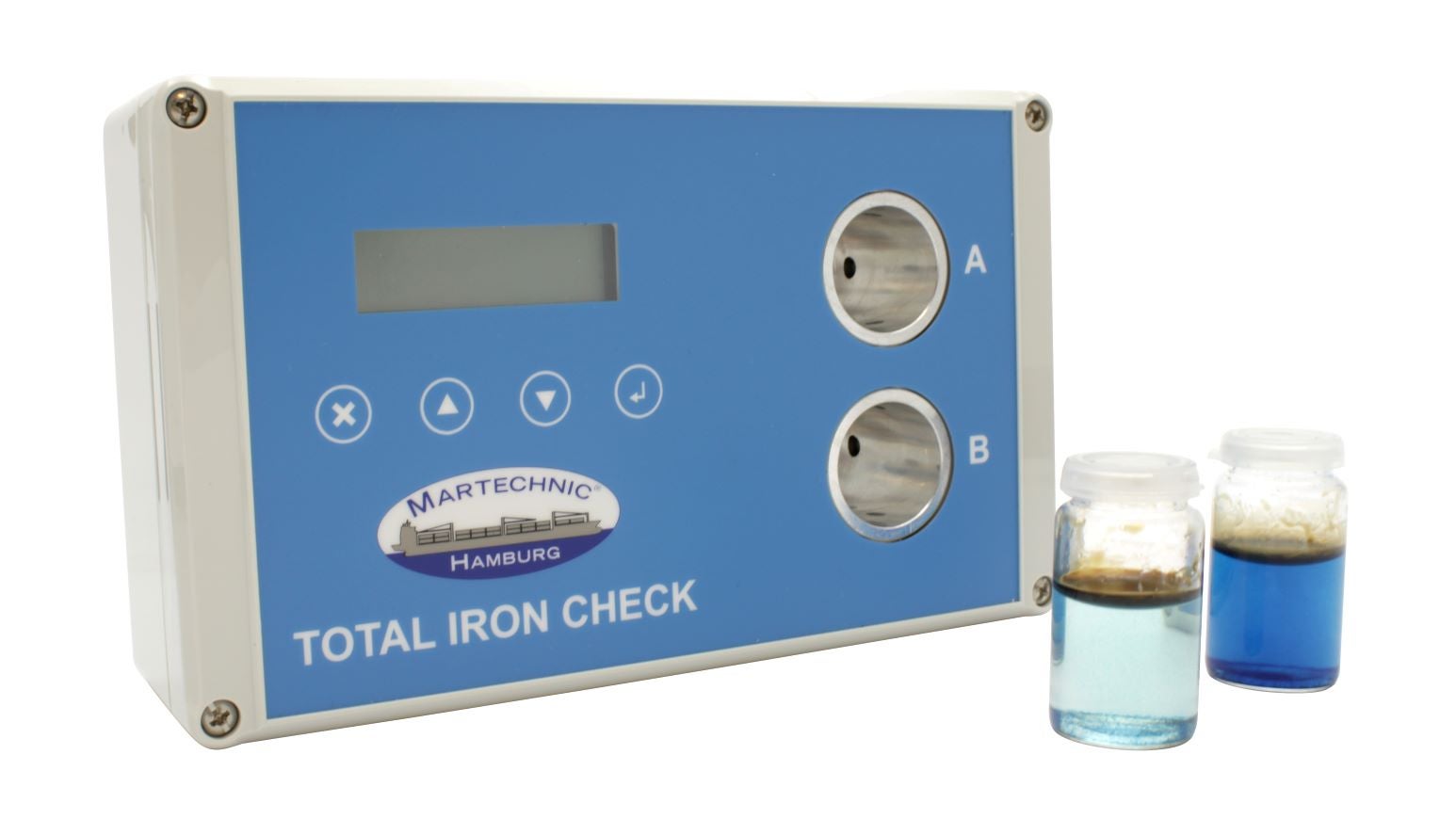

Martechnic® will present its new test kit Iron Check E; an electronic version of the proved measurement method of iron content in cylinder drain oil.

In June 2016, Martechnic® will be a part of two major international trade shows in Europe and will be exhibiting a wide range of its products designed to provide engineers and users with effective technical solutions for on-site oil quality management.

One of the objectives of ensuring the required quality of the heavy fuel oil on board of a vessel is to monitor it for the presence of cat fines. As cat fines are extremely abrasive particles of various sizes that can cause severe damages to the components of the engine system, the bunker fuel oil undergoes a purifying procedure in a separator prior to being used for a vessel's engine operation.

For upgrading, and for a continuous assessment of iron content in lube oil, the FE Sensor can be applied in the MT Modular Monitoring System from Martechnic®.

As oil condition, especially lube oil condition, is still one of the most important topics in shipping, Martechnic® is working on technical solutions to further develop products.

Martechnic® has announced it will be at the Marine Maintenance World Expo in Brussels. The world's only exhibition and conference dedicated to marine maintenance, repair tools, technologies and services, opens its doors from 14 - 16 October, with more than 50 speakers presenting must-see papers.

To determine the significance of iron content in lube oil, especially with regard to cylinder drain oil, Martechnic has developed an easy-to-handle iron test.

The most common contaminate of lube oil is water that causes problems and damage in machines and engines.

To provide a continuous and comprehensive assessment of the quality of lubricating and hydraulic oil, Martechnic® has designed and developed the MT Modular Monitoring System: an assembly of various sensors that measure different oil parameters in real-time.

Upon delivery the quality of bunker fuel has to be assessed taking into consideration its density, stability and compatibility parameters.

Iron concentration in cylinder drain oil is an important parameter to measure regularly in terms of the determination of engine wear condition, and in particular wear rate of cylinder components.

Catalyst fines (hard particles of abrasive nature consisting of aluminium and silicon oxide) often remain in bunker fuel after the catalytic cracking process of crude oil and are extremely harmful to engine parts.

The test device TWIN CHECK 4.0 has been developed and designed by Martechnic® in the framework of the digitalisation concept to provide customers with a cost-effective technical solution for regular on-site measurements of two critical oil parameters.

By installing the VISCOSITY & DENSITY SENSOR, maintenance costs can be decreased and oil change intervals could be extended.

The test device MT COOLANT CHECK simplifies the testing process by analysing water-based coolants with just one single measurement through a single coolant sample in a simulated cooling system.

Regular measurement of multiple oil parameters with on-board testing equipment provide engineers and users with accurate and in-depth information on the oil condition.

The corporate video gives an insight into Martechnic’s everyday business life and explains the advantages of the adoption of oil condition monitoring practices or in-service oil testing.

This video manual shows the detailed testing procedure of compatibility of different fuel oils, which is guided by ASTM D4740-04 (2014).

The test device MT CAT FINES CHECK allows for easy, quick, and accurate on-board determination of cat fines concentrations in heavy fuel oil (VLSFO and HSFO).

The test device TOTAL IRON CHECK is designed for onboard Cylinder Drain Oil (CDO) analysis to regularly monitor the degree of total iron concentration in cylinder drain oil (CDO).

The test device TWIN CHECK 4⋅0 is developed for regular on-board measurement of two crucial oil parameters: water-in-oil and base number (BN). This video manual shows the detailed procedure for measuring the base number (BN).

The test device TWIN CHECK 4⋅0 is developed for regular on-board measurement of two crucial oil parameters: water-in-oil and base number (BN). This video manual shows the detailed procedure for measuring the water in oil content.

The test device VISCO DENS PLUS enables prompt, on-board determination of two oil parameters, viscosity and density, in a single test procedure, applying three different temperatures (40°C, 50°C, and 80°C) to the same test tube.

At the SMM 2022, Martechnic celebrated its 25th corporate anniversary, with many international guests and long-term business partners.