Shaft Straightening for the Marine Industry

MarineShaft carries out repairs and straightening of propeller shafts for the marine industry.

MarineShaft is a modern company based on classic workmanship traditions. We carry out repairs of propeller equipment and rudder arrangements, specialising in class-approved cold straightening of propeller shafts and rudder stocks.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

MarineShaft is a modern company based on classic workmanship traditions. We carry out repairs of propeller equipment and rudder arrangements, specialising in class-approved cold straightening of propeller shafts and rudder stocks.

With our many years of experience and purpose-built equipment capable of pressing up to 6,000t, we are able to straighten shafts from 20mm to more than 1,500mm in diameter.

Cold straightening of propeller shafts and rudder stocks is a special technique that was developed more than 40 years ago. The technique has been completely tested and improved over the years and is fully approved by all the leading classification authorities. All work is completed in close cooperation with the classification authorities, with a certificate issued on each individual repair.

Even the biggest deflections can be straightened, after which they’re as good as new. Often a shaft that has been straightened by MarineShaft has a better straightness than that of a new shaft. We regularly achieve a straightness of 0.05mm or better, even on very big shafts. We have straightened shafts of more than 1,500mm in diameter and more than 25,000mm in length. Some of these shafts have been bored for push/pull rods.

Straightening of shafts is much faster than manufacturing new shafts. Many jobs can be completed within 24-48 hours from arrival at our workshop. When necessary, we work round the clock to ensure the best delivery times for our customers. We always have the capacity for urgent repairs and the experience to make the right decisions quickly.

Straightening is also a more economical solution than having new shafts manufactured. MarineShaft straightens propeller shafts and rudder stocks from all over the world. No matter where the propeller/rudder damage occurs, we can help you save money.

MarineShaft is among the leading companies when it comes to the manufacturing of propeller shafts and rudder stocks. Our flexible organisation makes us capable of switching production at very short notice, so new propeller shafts and rudder stocks can often be manufactured in a few days.

We have a large stock of class-approved steel. With Round steel bar in various sizes and grades up to 1,000mm in diameter and up to 18,000mm in length. We supply plates up to 150mm, propeller shafts with flange diameter up to 1,300mm and liners in stainless steel and bronze. All material is 3.2 class-certified.

We have a stock of class-approved steel in several large and very large dimensions – ready to be machined quickly. All material is 3.2 class-certified.

MarineShaft has great experience in reconditioning rudders and rudder arrangements. We perform the work in our workshop or on-site, always focusing on quality. Our reconditioned products are as good as new, thanks to our fast and economical process.

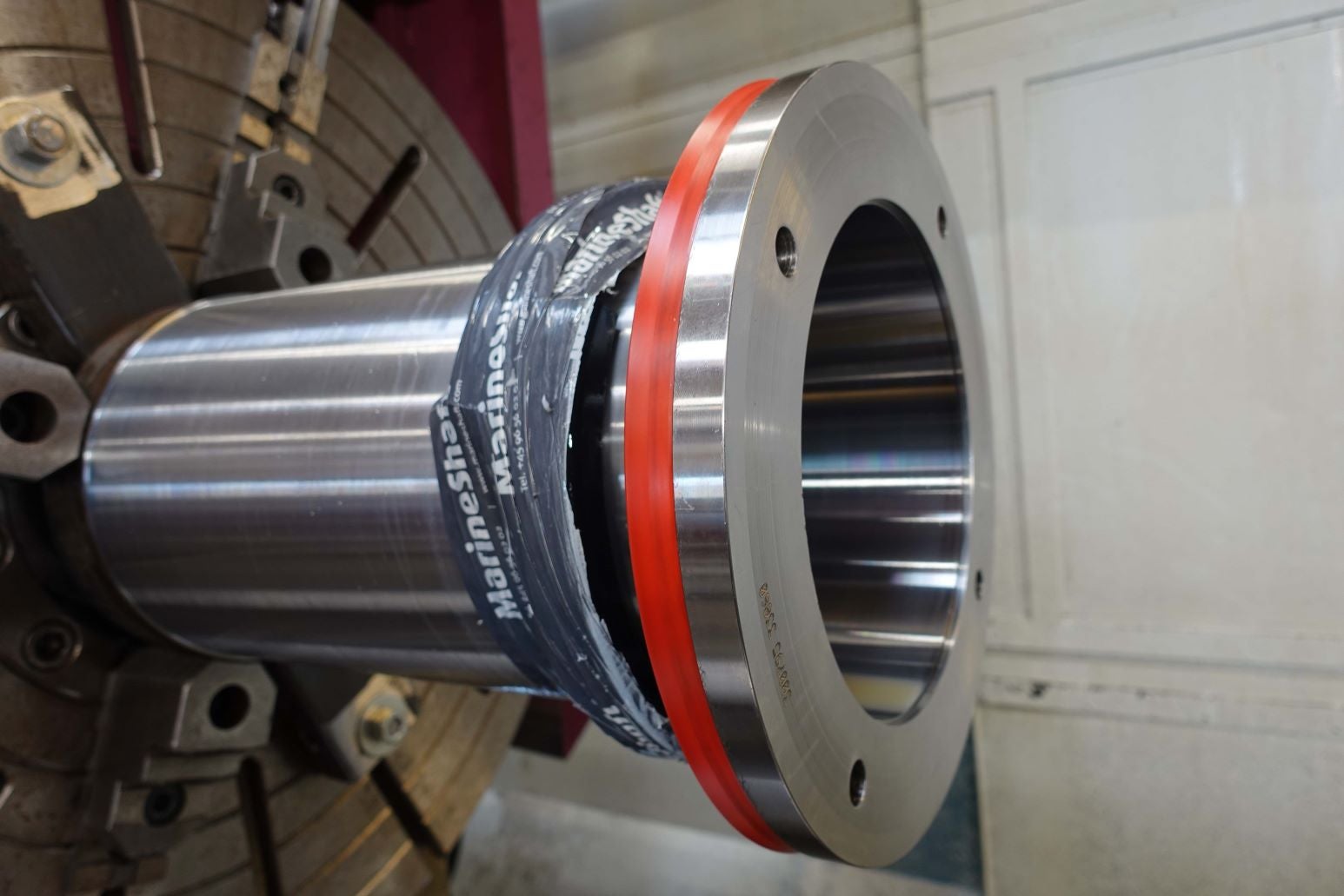

We also carry out complete reconditioning of propeller equipment, including shafts, propeller hubs and marine shaft sealing systems, as well as centrifugal casting of white metal bearings.

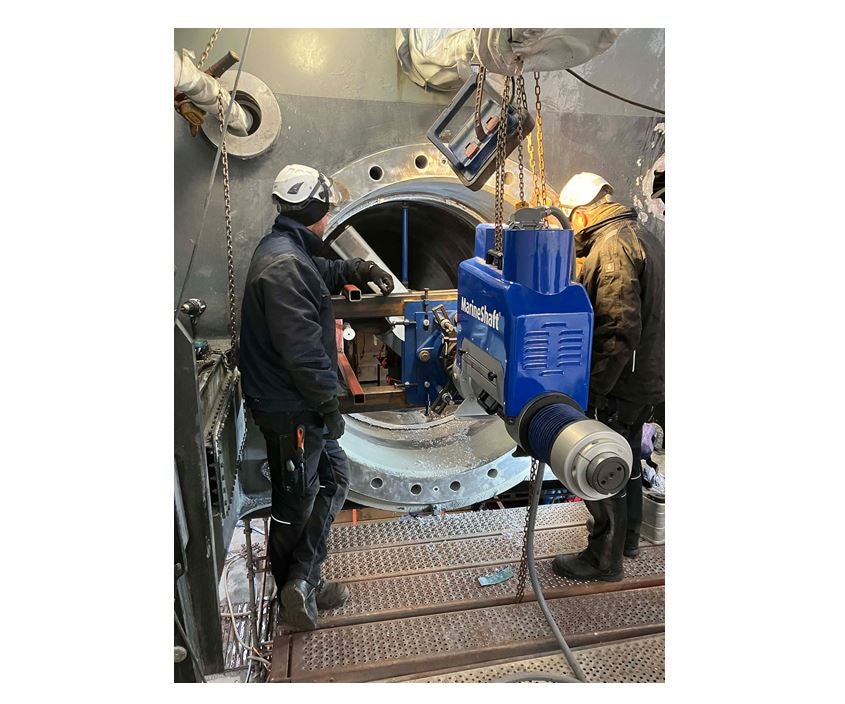

Our workforce is our main asset, with the experience to make fast decisions. Many of our employees have been in the business for more than 40 years. We have the experience and the equipment to solve any problem our customers may have with their propeller equipment or rudder arrangement. We can handle even very large dimensions, and when the job needs to be completed on-site we are able to send competent teams at short notice.

Use the form below to tell us what you need and we will reply with a complete quotation detailing delivery time and total price, including transportation and classification costs.

Transport and shipping worldwide is part of our service. We deliver wherever we are needed and work with reliable forwarding companies.

MarineShaft carries out repairs and straightening of propeller shafts for the marine industry.

MarineShaft specializes in cold straightening of propeller shafts, intermediate shafts, and rudder stocks.

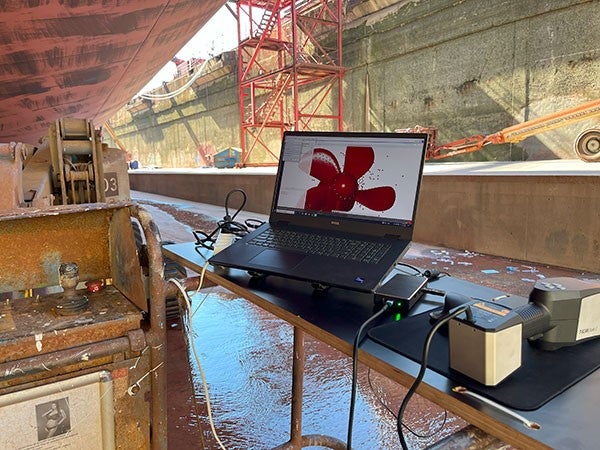

We share two recent case studies showcasing how our 3D scanning equipment enabled cost-effective repair solutions.

We recently completed a repair job for the famous National Geographic Explorer, a vessel that sails in the waters of Antarctica during winter and the Arctic in summer.

A short repair time is an important factor for most of our repair work.

When crucial components like shaft seal liners suffer damage, owners face the need for urgent replacement or repair solutions.

MarineShaft received the order, and the shipyard arranged to transport the two shafts to our workshop facilities in Hirtshals.

It is almost Christmas, and this December wraps up a busy year, to say the least. We want to start with a big "Thank you" for the repair and manufacturing jobs placed with us during the year.

Both projects involved the repair and manufacturing of new parts/components. For many of our in-house jobs, repair and replacement go hand in hand. Keeping material in stock is of high value and importance to guarantee a short delivery time.

MarineShaft has made a strategic move by investing in the latest 3D scanning equipment. This purchase is in line with our commitment to staying at the forefront of technology.

A chemical tanker suffered a bearing failure off the coast of Sweden. The vessel was towed to Denmark and lay at anchorage of Skagen.

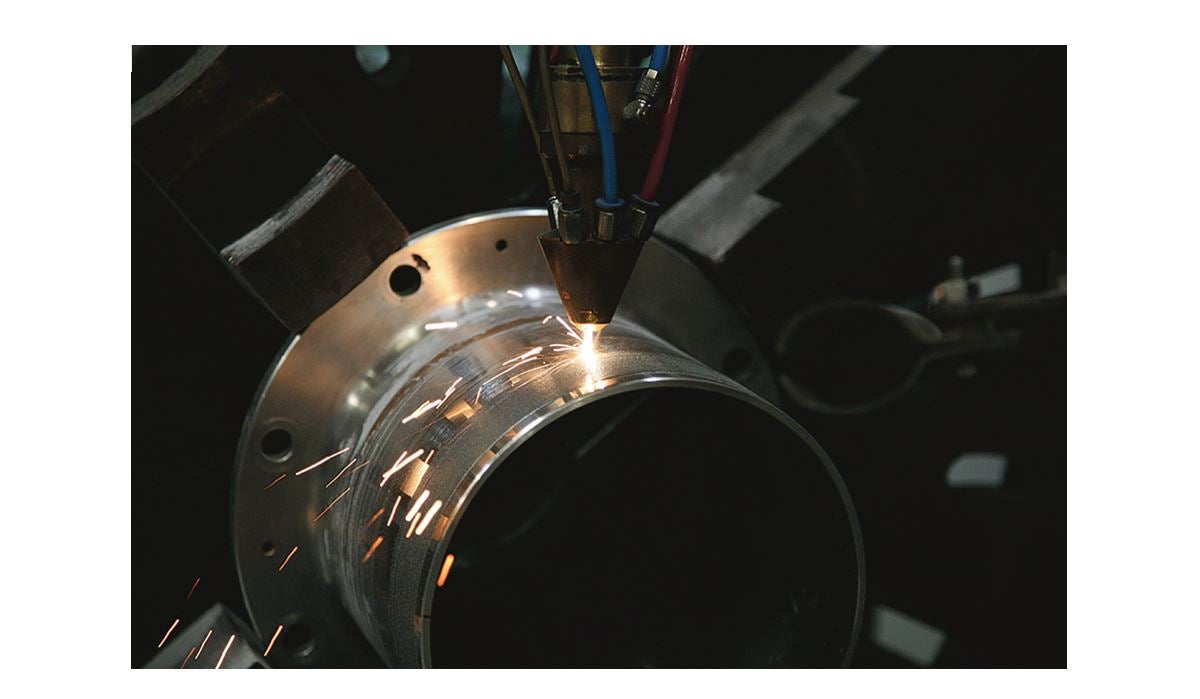

From day one, our goal has been to attain full class approval to use laser cladding on various materials, and we have achieved our goal.

Using our lathes was not an option, and we had to find a different solution to machine the sealing surface before and after laser cladding.

In December, we completed a a case that included both in-house and on-site work from MarineShaft.

Marineshaft's new machine has a capacity of up to 1,600mm in diameter.

MarineShaft came to the rescue when a chemical tanker needed a new coupling and a fast repair of its propeller equipment.

This cold straightening repair case of a tail shaft is quite spectacular, not due to the extent of deflection, but due to its size!