Datum Electronics is a world-leading supplier of marine shaft power meters. Our competitively priced, flexible systems are capable of measuring the on-shaft torque and power of a ship on shafts from 150mm to 1,100mm (and above) diameters.

We supply solutions for monitoring ship performance to a range of high-profile clients including the Royal Navy, having installed 15 shaft power meter systems on their Sandown and Hunt class vessels. These needed to meet the most stringent test requirements regarding environmental and electromagnetic radiation due to their application on minehunters. We are constantly working to develop systems to meet the challenges of both the civilian and military sectors.

Datum Electronics solutions can be used to evaluate and improve the efficiency of ships, monitor engine performance, monitor propulsion condition and reduce fuel consumption.

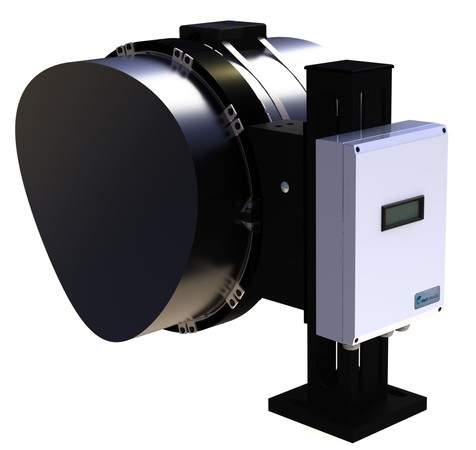

Commercial marine shaft power meter

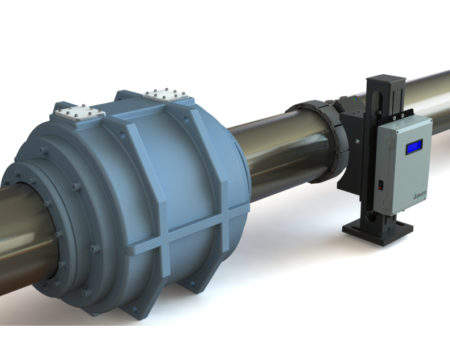

The Datum Electronics commercial marine shaft power meter has been developed to meet the requirements of marine industry customers by providing continuous power output measurements, as well as aiding fuel economy and equipment maintenance planning.

Robust, permanent, modular and simple to install, the commercial marine shaft power meter accurately monitors the efficiency and performance of the ship’s transmission systems, leading to large savings on running costs.

Monitoring actual power levels provides an accurate reference point in assessing:

- Propeller condition

- Hull condition

- Ship condition changes

- Engine performance monitoring

- Propulsion monitoring

- Operational efficiency planning

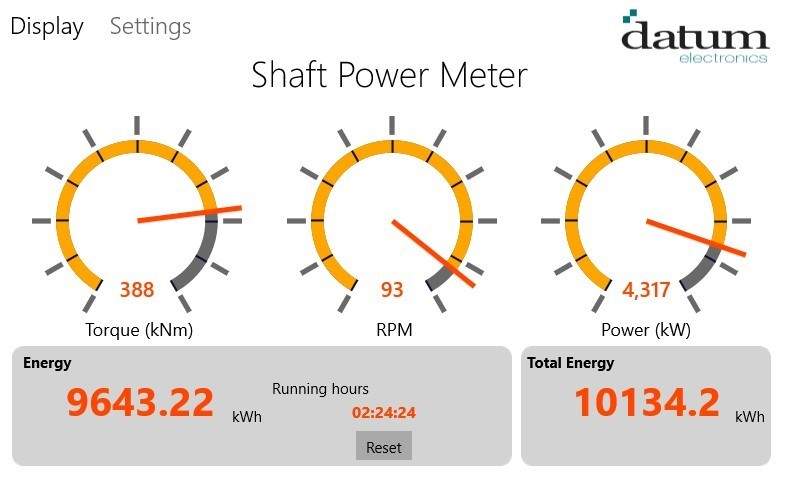

This tool will measure on-shaft torque, shaft rotation speed and the power going through the shaft. The stator uses a single-point design and does not require mounting around the shaft, allowing for a fast, simple and less intrusive installation compared with conventional designs.

The company’s power and torque meters have a modular design and can be used on shafts of 150mm-1,100mm diameter, with rotational speeds of up to 900rpm. Standard output is RS485, but this can be upgraded to USB, ModBus, Ethernet, RS232 and analogues (0-10V/4-20mA).

In addition, systems for power and torque measurement can be used with our display panel for either single or dual-shaft applications. Unlike other companies, we can also write algorithms and protocols to suit various customer system needs.

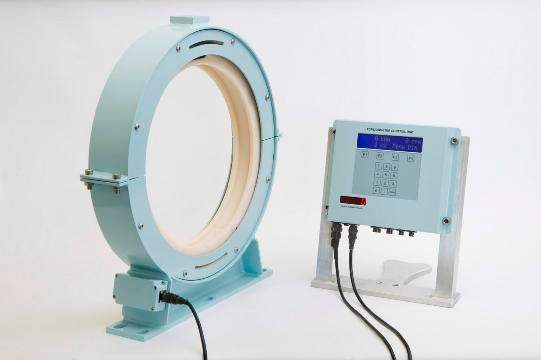

Shaft power measurement kit

Datum Electronics temporary torque and power measuring systems monitor the on-shaft torque for trial applications on rotating shafts of 30mm-1,100mm diameter (and beyond this if required). Whether used for the simple testing of power levels or as a key tool in extended trials to assess fuel efficiency, the series 430 kit is easy to install, test and operate.

The system logs directly on to a PC or laptop with the aid of its software. Other advantages include:

- Portable and lightweight design

- User-friendly software

- Easy to install with a step-by-step guide in less than 30 minutes

- Measuring shaft power, torque and speed as a basic function

- Various digital and analog output options

- Logs, records and displays ‘real time’ data

- Compatible with two data channels and shaft speed

As well as measuring torque, the instrumentation can be used to verify power outputs from engines and motors, as well as analysing other types of data, including:

- Power transmission

- Shaft vibration

- Torque trials

- Peak torque levels

- Power delivery

- Power transients

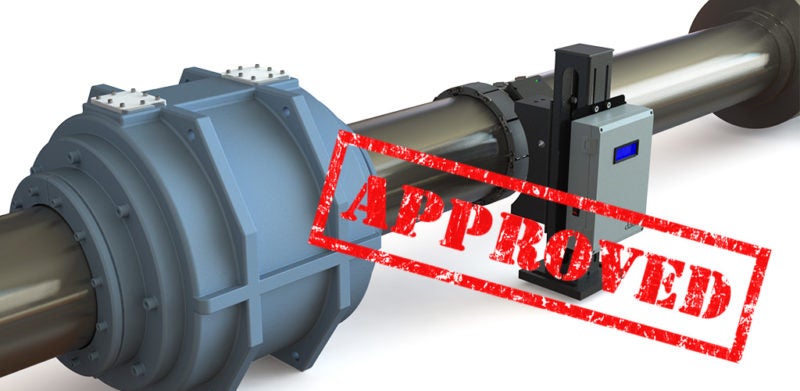

Marine shaft power meter system for military vessels

The Datum Electronics marine shaft power meter system assesses and monitors propeller shafts on ships, by measuring shaft speed, power and torque. Originally designed for use by the Royal Navy, later variations have been provided for the Indian Navy, Australian Navy and Korean Navy.

The company’s propeller shaft power meters have been through rigorous UK MOD and USA MIL testing programmes for the harshest of environments, and are therefore verified in a number of marine conditions, including:

- MIL Spec std. 901-D shock

- 167-1A 2005 Vibration

- Safety Case to JSP430

- Shock to Def Stan 08-120

- EMC to Def Stan 59-41

- Selection of marine shaft power meters Def Stan 02-606

- Magnetic Ranging to 08-123 DS31

Other environmental tests will include Def Stan 08-123 DS28 (shock), D25 (vibration), DS24 (contamination), DS9 (temperature and humidity) and DS21 (salt atmosphere).

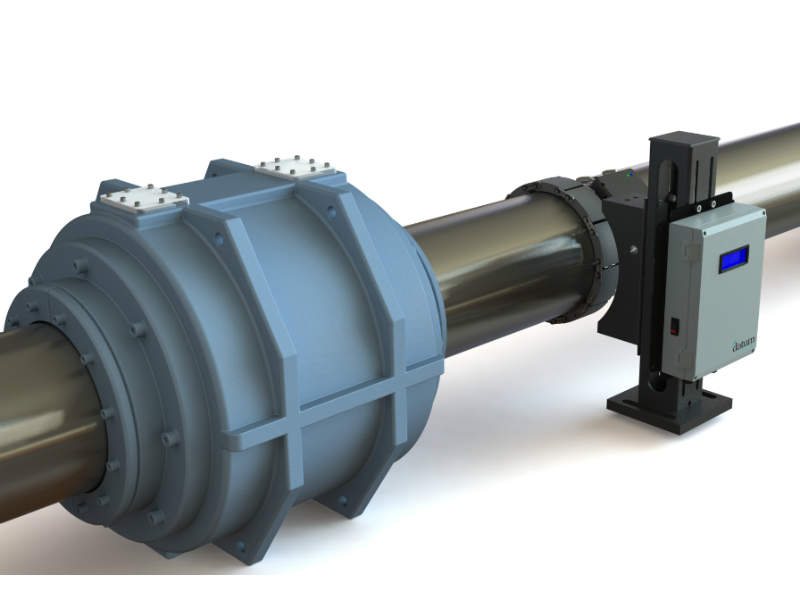

The series 420 torsionmeter system can be configured for single-shaft or multiple-shaft use (two, three or four shafts), in order to provide accurate non-contact shaft measurement. A fitted shaft unit measures torsional strain and rotational speed, with a separate stator unit to transmit the data to the control unit.

This system fits shafts of 160mm-1,100mm diameter, with stator housings manufactured for a range of shaft sizes:

- Size 1: shafts 160mm-250mm

- Size 2: shafts 250mm-350mm

- Size 3: shafts 350mm-500mm

- Size 4: shafts 500mm-650mm

- Size 5: shafts 640mm-800mm

- Size 6: shafts 800mm-1,100mm

Installation, training and consultancy

All of our systems are supplied along with the required product information and user handbooks. Full training can be provided, either on-site by one of our installation engineers or at our specialist facility in the UK.

Datum Electronics has expertise in a range of fields including electronics, torsional vibration, field testing, strain gauging and installation. Contact us with your problem and we will endeavour to find a workable solution for you.